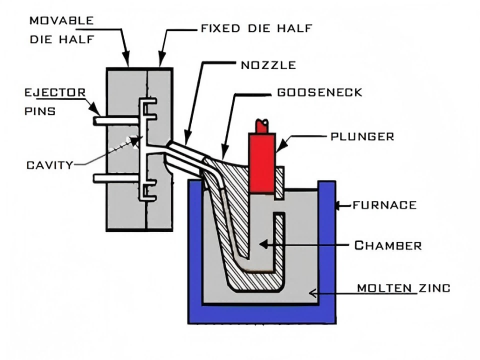

In die casting, nozzles play a crucial role in the injection system, which is responsible for delivering molten metal into the die cavity.

This article will detail the specific roles of nozzles in flow control and sealing, temperature management and thermal balance, and enhancing production efficiency.

It will also analyze key points in their design and maintenance, concluding with a HAICHEN case study showing how high-quality nozzles in die casting solve real production challenges.

The function of nozzles in die casting

- Flow Control

- Temperature Management

- Improve Casting Quality

- Increase Production Efficiency

- Minimize Material Waste

Flow Control

Regulate Molten Metal Flow:

Nozzles control the flow rate and direction of the molten metal as it enters the mold cavity.

This ensures a consistent and controlled filling process, preventing defects such as turbulence, air entrapment, and incomplete filling.

Prevent Backflow:

In some designs, nozzles prevent the molten metal from flowing back into the reservoir or supply system after it has been injected into the mold.

This is achieved by forming a solidified plug in the nozzle or using check valves.

Temperature Management

Maintain Molten Metal Temperature:

Nozzles can ensure that the molten metal remains at the desired temperature as it flows through the nozzle and into the mold.

This helps maintain the fluidity of the metal and ensures proper filling of the mold cavity.

Prevent Solidification:

By controlling the temperature, nozzles prevent the molten metal from solidifying prematurely in the nozzle, which could block the flow and disrupt the casting process.

Improve Casting Quality

Enhance Surface Finish:

Properly designed nozzles can help achieve a smoother and more uniform surface finish on the final casting.

By controlling the flow and temperature of the molten metal, they reduce the formation of surface defects such as porosity and inclusions.

Enable Complex Geometries:

Nozzles allow for the production of complex and intricate parts with thin walls and detailed features.

They can direct the molten metal precisely into the mold cavity, filling even the most intricate sections.

Increase Production Efficiency

Reduce Cycle Time:

Efficient nozzles can help reduce the overall cycle time of the die casting process. By ensuring a smooth and consistent flow of molten metal, they minimize delays and interruptions, allowing for faster production.

Minimize Material Waste:

Some nozzle designs, such as those used in heated-manifold direct-injection die casting, eliminate the need for sprues, gates, and runners. This reduces material waste and lowers production costs.

Thermal Balance Management and Service Life

Nozzles operate under continuous impact from hot metal; their thermal management capability is crucial for process stability and their own lifespan.

- Maintaining Molten Metal Temperature Stability

- Resistance to Thermal Fatigue and Cooling

- Preventing Cold Slug Blockage and Sticking

Maintaining Molten Metal Temperature Stability

Nozzles need good insulation or heating systems to minimize temperature drop as metal passes through. This is especially important for thin-wall castings or alloys requiring high fluidity in die casting, preventing cold shuts or insufficient filling caused by low metal front temperature.

Resistance to Thermal Fatigue and Cooling

Nozzles endure severe thermal cycling (heated and cooled each shot). The material must have excellent thermal fatigue resistance. Many nozzles incorporate cooling channels to control operating temperature and delay heat checking, a core measure for extending nozzle life in die casting.

Preventing Cold Slug Blockage and Sticking

In cold chamber die casting, if the nozzle temperature is too low, the first metal to contact it can solidify into a “cold slug,” potentially blocking the channel. Proper nozzle temperature and surface treatments reduce sticking of aluminum or zinc, ensuring smooth flow.

Nozzle Selection, Maintenance, and Performance Enhancement

Correct selection and maintenance are fundamental to fully utilizing nozzle function and ensuring continuous production.

- Selection Principles Based on Product and Material

- Regular Inspection, Cleaning, and Replacement Cycles

- Impact of Maintenance on Quality and Cost

Selection Principles Based on Product and Material

When selecting nozzles in die casting, consider the machine type, product characteristics, and alloy. Producing large aluminum parts typically requires nozzles with larger inner diameters and higher thermal shock resistance, while precision zinc parts may need nozzles with higher bore accuracy.

Regular Inspection, Cleaning, and Replacement Cycles

A preventive maintenance schedule for nozzles is essential. Regular checks should include inner bore wear, cracking, corrosion, and sealing face flatness. Timely removal of oxide scale and metal slag, along with scheduled replacement, prevents unplanned downtime from sudden failure.

Impact of Maintenance on Quality and Cost

Well-maintained nozzles stabilize injection parameters, directly improving product yield and reducing overall cost by minimizing unplanned stops and scrap. Neglecting maintenance leads to seal failure and unstable flow, causing batch quality defects.

Haichen die casting nozzle

Haichen is a well-known manufacturer of cold chamber, hot chamber die casting machines and components, including die casting nozzles. Our nozzles can meet the high demands of the die casting industry, ensuring precision, durability, and efficiency in the injection process.

Features of Haichen Die Casting Nozzles

- High-Quality Materials: Haichen nozzles are typically made from premium materials such as H13 hot-work tool steel or other high-grade alloys. These materials provide excellent resistance to thermal fatigue, wear, and corrosion, ensuring a longer lifespan.

- Precision Engineering: The nozzles ensure a perfect fit and seal between the injection system and the die. This minimizes leakage and ensures consistent metal flow.

- Optimized Design: Haichen nozzles can reduce turbulence and improve the flow of molten metal, which helps in achieving high-quality castings with fewer defects.

- Thermal Management: The nozzles can handle high temperatures and maintain thermal stability, preventing premature solidification of the molten metal.

- Compatibility: Haichen nozzles are designed to be compatible with a wide range of die casting machines and dies, making them versatile for various applications.

Case: Solving Internal Porosity in Automotive Engine Components

A customer producing aluminum cylinder heads faced persistent X-ray porosity rejection in specific areas. HAICHEN analysis found that the original nozzle’s poor internal streamlining caused turbulent flow and air entrapment. Switching to a HAICHEN-designed streamlined nozzle significantly improved flow stability. This change reduced the porosity defect rate for that part from 3.5% to below 0.8%, meeting the customer’s strict standard.

Although small, the nozzle in die casting is a crucial functional component connecting the equipment and the mold, controlling the final behavior of the molten metal. It plays an irreplaceable role in flow sealing, thermal management, and quality and efficiency improvement. Proper selection and maintenance are fundamental to ensuring its functionality.