Die casting PLC configuration includes importance of PLC selection and system configuration, optimize and control of die casting process parameters etc.

The PLC control system of a die casting machine is responsible for the sequential, parallel, and exception handling of all process flows. Including hydraulic injection, mold closing, temperature/pressure monitoring, silo supply, and safety protection.

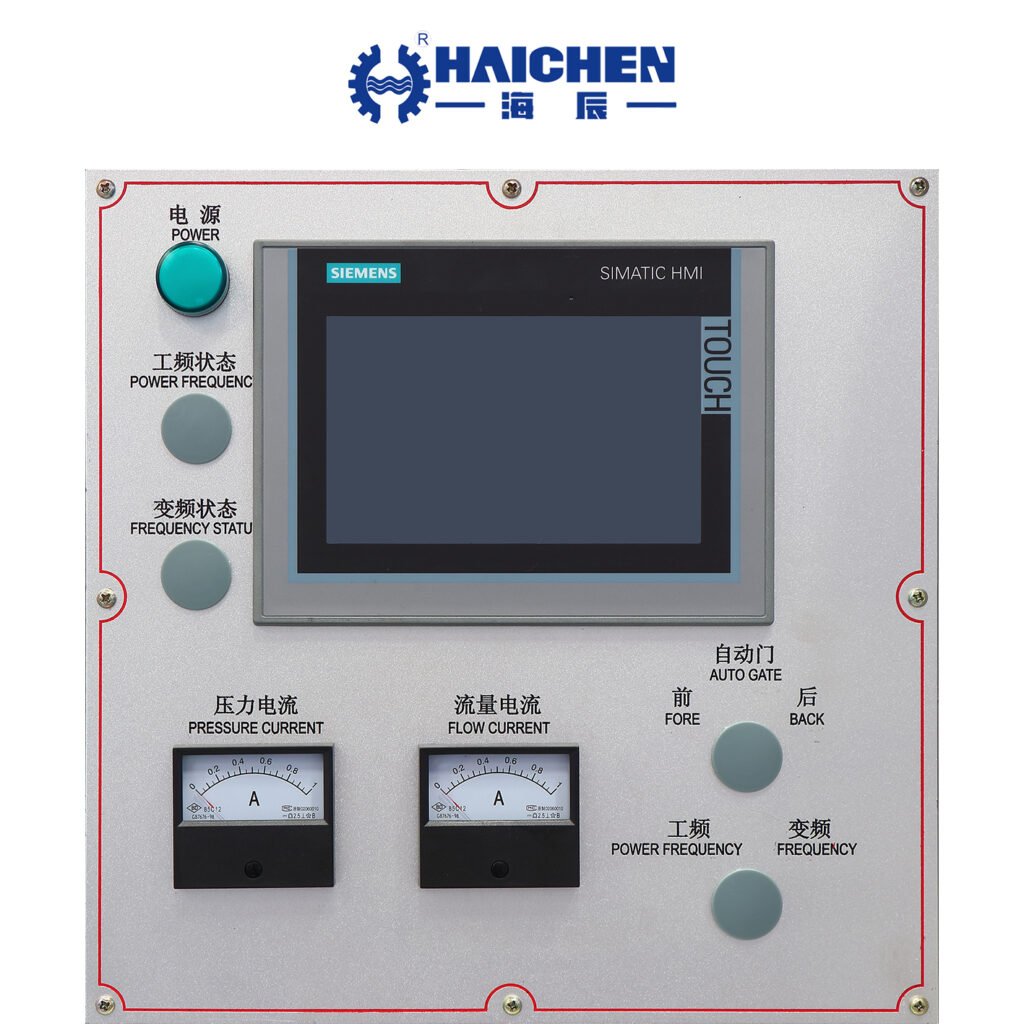

A typical PLC control structure includes a CPU, digital/analog I/O, communication modules. And an HMI (human-machine interface), and field wiring to hydraulic valves, sensors, and actuators.

Below are Haichen die casting machine PLC configuration features:

- Importance of PLC selection and system configuration

- Optimization and control of die casting process parameters

- Advanced model-based control methods

- Application of Automation and Artificial Intelligence

- Environmental adaptability and system reliability

Importance of PLC selection and system configuration

PLC (Programmable Logic Controller) plays a vital role in the control system of die casting machines.

In order to design a control system with the best performance-price ratio, technicians need to master the general methods and principles of PLC selection and system configuration.

This includes the selection of machine models, the selection of hardware and software conditions, the adaptability of the supporting environment, etc.

High-speed response

Given the short high-pressure casting cycle (within seconds), the PLC must possess millisecond-level response capability to precisely control injection and holding pressure times.

Robust analogue processing

The casting process involves high-precision pressure, displacement, and temperature control, requiring the PLC to utilise high-accuracy analogue input/output modules.

Complex Logic Control

From mould coolant circulation to synchronised control of injection cylinders, the PLC must manage intricate logic sequences.

Optimization and control of die casting process parameters

Optimization of die casting process parameters is the key to ensuring product quality.

For example, through experimental design and optimization methods, it can improve both casting quality and mold life.

In addition, studies have shown that parameters in the die casting process (such as first stage speed, second stage speed, first stage length, and injection pressure) have a significant effect on the porosity of the casting. The optimization of these parameters can be precisely controlled by the PLC system.

Injection parameters

Speed, stroke, acceleration

Pressurisation parameters

Time, pressure, pressure hold time

Cooling parameters

Cooling water valve opening, cooling time

Temperature parameters

Mould temperature, feed temperature

Advanced model-based control methods

The high pressure die casting (HPDC) process is characterized by rapid filling and rapid cooling, which has an important impact on the quality of the mold and casting.

In order to simulate and optimize this process, advanced modeling methods can be used to predict the temperature field and pressure distribution. These models can be integrated into the PLC system for more precise process control.

Core Mechanism

Employing advanced modelling techniques (such as finite element analysis) to predict temperature and pressure fields during molten aluminium filling, and integrating these models into the PLC system to achieve closed-loop feedback control, thereby ensuring consistent quality for every casting produced.

Software Implementation Path

From Model to Code, it need implement through model Development and Reduction, algorithm Design and simulation, and code generation and deployment.

Application of Automation and Artificial Intelligence

In recent years, artificial intelligence technologies (such as neural networks) have been used to optimize die-casting process parameters.

For example, through a MATLAB-based neural network model, it can reduce the time and cost of traditional trial-and-error methods.

This technology can be integrated into the PLC system to further improve the level of automation.

High-voltage I/O module

Specifically engineered to withstand noise and electromagnetic interference from high-pressure hydraulic systems in die-casting machines, ensuring signal accuracy for critical components such as suction valves and hydraulic pumps.

High-speed counter/clock

Employed for precise control of injection speed (R/C) and holding pressure time, which are key parameters determining casting quality.

High-Speed Communication Module

Typically employs Ethernet/IP, PROFINET, or CC-Link to facilitate real-time data exchange with upper-level systems (SCADA/HMI) and robotic arms (e.g., part-removal arms).

Safety Module (SafetyPLC)

Monitors emergency stop buttons, door light curtains, and similar safety devices to comply with standards such as ISO 13849, ensuring immediate shutdown during abnormal conditions.

HAICHEN’s Practical Application of PLC Configuration

We configure PLCs to solve specific production challenges for our clients.

Optimize Cycle Time

One of Haichen customers who produced aluminum housings. Their cycle time was too long, limiting output. HAICHEN engineers analyzed their PLC sequence. We found unnecessary delays between ejection and spray. By reprogramming the PLC to start the sprayer earlier and run it in parallel with other actions, we reduced the cycle time by 12%. This increased their daily production significantly.

Deliver Intelligent Control for Reliability

As a die casting machine manufactuer for more than 10years., HAICHEN’s advantage is deep system integration. We don’t just install a standard PLC. Our engineers configure it for your specific mold, alloy, and production goals. This tailored PLC configuration ensures our machines run with high stability and repeatability. For Turkish manufacturers, this means less downtime, easier operation, and a machine that is perfectly tuned for your products from day one.

Environmental adaptability and system reliability

When selecting a PLC, its environmental adaptability should also be considered, such as the impact of conditions such as temperature and humidity on the equipment. In addition, the reliability of the PLC system is crucial to ensure the stability and safety of the die-casting process.

Above all, the PLC configuration of die-casting machines needs to comprehensively consider factors such as process parameter optimization, advanced control methods, automation technology, and environmental adaptability. By rationally selecting PLC models and combining advanced modeling and artificial intelligence technologies, it can significantly improve the performance and product quality of die-casting machines.

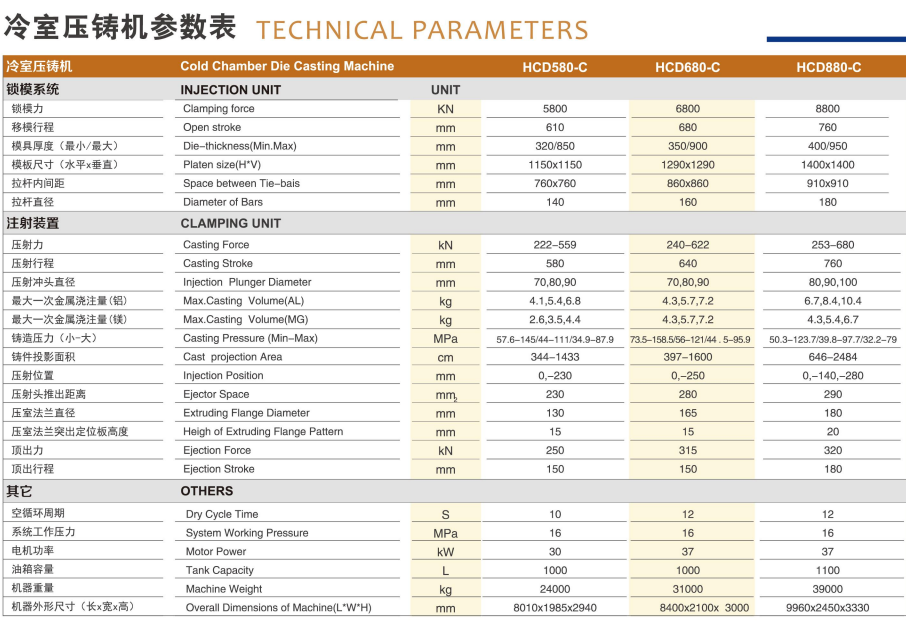

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.