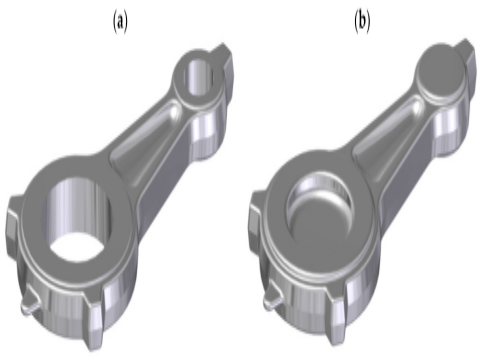

The connecting rod in die casting consists of several key parts that work together to ensure strength and performance.

Main Components of Connecting Rod in die casting

The connecting rod in die casting consists of several key parts that work together to ensure strength and performance. Below are the main components:

Big End:

The big end is the section that connects to the crankshaft’s crank pin. It is typically secured by special nuts and bolts to ensure a secure connection.

Small End:

The small end connects to the piston through the gudgeon pin (also known as the piston pin or wrist pin). In some engines, it connects to the crosshead.

Rod:

The rod is the central portion that connects the big end to the small end. It may have an I – beam or H – beam shape.

I – beam rods are more common due to their ease of manufacturing and ability to support greater loads while reducing deflections for the same amount of material. H – beam rods are generally more expensive and rigid, making them suitable for higher compressive forces.

Bush:

A bush bearing is used on the small end to facilitate smooth movement between the piston and the small end. It operates under continuous metal – to – metal contact with the piston pin and must withstand high cyclic loading.

Bearing Insert:

These are semi – circular pieces of low – friction material placed between the connecting rod and the crankshaft at the big end. They prevent metal – to – metal contact and help maintain an oil film between them, increasing the durability of both components.

Bolt and Nut:

Bolts and nuts secure the connecting rod at the big end and sometimes at the small end (when connected to a crosshead).

These fasteners are highly stressed and must endure fluctuating tensile stresses, bending stresses, and shear stresses during operation.

Considerations in Die Casting

When manufacturing connecting rods through die casting, the following factors are important.

Material Selection :Die casting typically uses materials like aluminum alloys due to their high strength – to – weight ratio and ease of casting. However, the choice of material depends on the specific application and required mechanical properties.

Design for Manufacturability :The design of the connecting rod must consider the die casting process. This includes ensuring proper draft angles, minimizing undercuts, and designing the part to allow for easy ejection from the mold.

Surface Finish and Accuracy :Die casting can produce components with high surface finish and dimensional accuracy. This is beneficial for connecting rods, as it reduces the need for secondary machining operations and ensures proper fit and function.

Weight Reduction :Die casting allows for the production of lightweight components, which is advantageous for connecting rods as it helps reduce the overall weight of the engine while maintaining structural integrity.

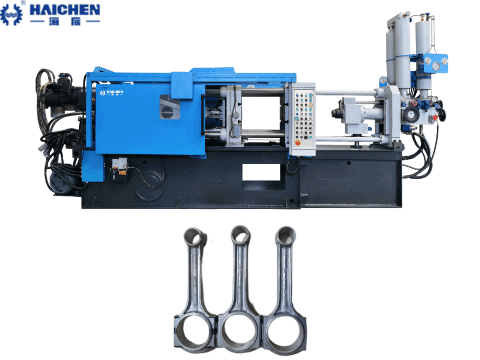

Die casting connecting rod supplier: Haichen Machinery

Haichen Machinery appears to be a supplier specializing in die-cast connecting rods or related components. We supple Cold Chamber Die Casting Machines and Hot Chamber Die Casting Machines except die casting components.

Our connecting rod typically made from aluminum or magnesium alloys, reducing weight vs. steel forged rods. And lower reciprocating mass improves engine efficiency, reduces vibration, and enhances fuel economy (key for automotive applications).

If there is any demand, welcome to consult us for more information.