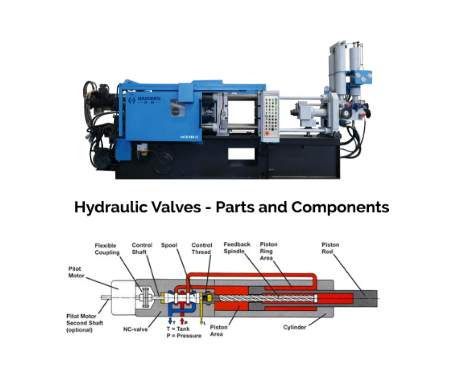

Hydraulic valve is a key components in die casting systems, used to precisely control the flow, pressure, and direction of hydraulic fluids.

Thereby driving various actions of die casting machines, ensuring efficient, safe, and high-quality casting processes.

The performance of hydraulic valves directly affects the quality, production efficiency, and equipment lifespan of die castings.

Modern die casting machines often use computerized control to replace older manual valves to improve repeatability and reduce wear,so as Haichen.

Hydraulic valve in die casting

Die casting technology is characterized by high energy consumption, for example, starting an automated process or heating the metal to high temperatures before injecting the mold during the die casting process requires a lot of energy.

Therefore, the hydraulic valves of die casting machines must ensure high reliability, repeatability and precision, which is essential in stages such as mold clamping or finishing with trimming machines.

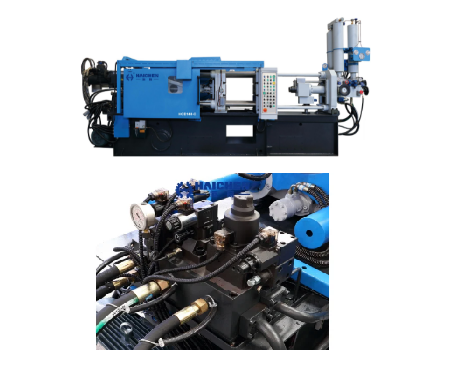

Haichen‘s hydraulic valves have been tested and verified by many customers for many years.

We worked with our customers to select the hydraulic valve that best suited the needs of the die casting process and received positive feedback.

Technical challenges and developments in hydraulic valves

Firstly, the closing response time of hydraulic vacuum valves may be insufficient, causing metal feeding and mold failures.

Therefore, control schemes such as PLC-based signal control require enhancement to achieve ultra-fast response.

Secondly, modern die-casting machines utilize computerized controllers to improve accuracy, while older machines rely on manual valves with variable settings, adversely affecting product quality.

Thirdly, integrated die-casting molds demand multiple hydraulic vacuum valves, but the integration of hydraulic cylinders into the mold increases system complexity.

The function of the hydraulic valve in die casting

Without proper hydraulic valve function, die casting machines would suffer from inconsistent fills, defects (porosity, flash), and mechanical failures.

- Control of Fluid Flow and Direction

- Speed Control

- Enabling Automated and Precise Operations

- Integration with Accumulators

- Safety and Reliability

- Adapt to different process needs

Control of Fluid Flow and Direction

Hydraulic valves regulate the flow of hydraulic fluid within the system.

They can stop the flow, allow it to pass, or change its direction.

This precise control is crucial for managing the movement of various components in the die casting machine, such as the plunger that injects molten metal into the mold.

Speed Control

By regulating the flow rate of hydraulic fluid, these valves control the speed of actuators.

In die casting, this means they can manage the speed at which the plunger moves during the injection phase.

This is important for achieving the desired filling characteristics of the mold.

For example, a two-stage valve can provide a fast response and precise control over the injection speed, ensuring optimal filling and reducing defects.

Enabling Automated and Precise Operations

Hydraulic valves enable the automation and precision required in modern die casting processes.

They can be controlled by external signals, such as electrical or hydraulic signals, allowing for complex and dynamic adjustments.

This level of control is essential for producing high-quality castings with consistent dimensions and properties.

Integration with Accumulators

Hydraulic valves work in conjunction with accumulators to provide a rapid and powerful injection of molten metal.

Accumulators store hydraulic fluid under pressure and release it quickly when needed.

The valves direct this fluid to the injection cylinder, ensuring a smooth and forceful injection process.

Safety and Reliability

By ensuring proper fluid flow, pressure, and movement control, hydraulic valves contribute to the safe and reliable operation of the die casting machine.

They help prevent malfunctions and ensure that the machine operates within its designed parameters.

Adapt to different process needs

Hydraulic valves can be customized according to different die casting process needs.

For example, in the high-pressure die casting process, a hydraulic vacuum valve can feed the molten aluminum into the vacuum valve at high speed start-up and close it when it is done to prevent the molten aluminum from clogging.

In addition, the hydraulic valve can also adjust the working mode according to the specific process parameters to adapt to different production conditions.

How to Choose the Ideal Hydraulic Valve for Die-Casting Machines

To optimize the performance of a die-casting machine, selecting the right hydraulic valve is crucial.

The perfect hydraulic valve can greatly enhance efficiency, precision, and overall production quality.

If you don’t know how to choose, you can consult Haichen.

- Flow Control Accuracy: Precise control over the hydraulic fluid flow ensures consistency in pressure and movement, which is essential for producing high-quality castings.

- Temperature Resistance: Valves must withstand high temperatures without compromising performance.

- Contamination Resistance: Valves must resist contamination in the dusty environment of die-casting plants to maintain long-term reliability.

- Precision Valve Core Design: Choose valves with a carefully designed core to precisely control fluid flow.

Haichen die casting hydraulic valve supplier

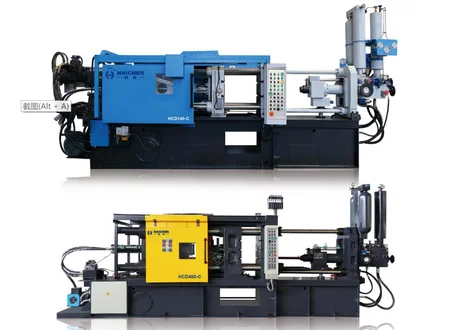

Haichen is a well-known Chinese manufacturer of die casting machines and related components, including hydraulic valves.

Key Advantages of Haichen Die Casting Hydraulic Valves

High Precision & Stability

- Accurate flow and pressure control ensure consistent injection speeds and clamping force, reducing defects like porosity or flash.

- Stable performance under high-pressure conditions (typical in die casting).

Durability & Long Service Life

- Made from high-quality materials resistant to heat, pressure, and hydraulic fluid erosion.

- Robust sealing technology minimizes leaks, even under frequent high-pressure cycles.

Energy Efficiency

- Optimized hydraulic circuits reduce power consumption, lowering operational costs.

- Some models feature proportional or servo valves for better energy management.

Customization & Compatibility

- Valves are tailored for Haichen die casting machines, ensuring seamless integration.

- Can be adapted for different casting processes (aluminum, zinc, magnesium).