Gooseneck cost optimization is a comprehensive process that involves balancing design, materials, processes, and innovative technologies.

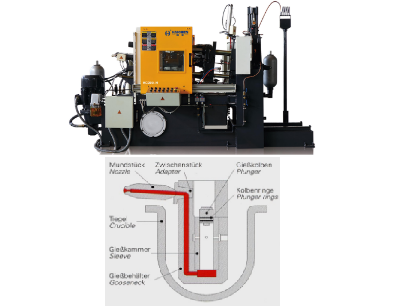

Specifically, the gooseneck, a curved conduit, actively transports molten metal from the furnace to the mold cavity .

Furthermore, its core functions include controlling metal flow to ensure smooth and rapid filling , resisting high temperatures up to 600-650°C and pressures of 10-70 MPa , and ensuring tightness to prevent leakage during injection.

Gooseneck function

- Metal Transfer: The gooseneck’s primary function is to act as a nozzle-like pathway for the molten metal.

- Submersion: It is submerged in the furnace holding the molten metal, allowing it to fill with the liquid.

- Injection: A plunger then forces the molten metal up through the gooseneck and into the die cavity.

- Temperature Control: The gooseneck must maintain the metal’s temperature. It is crucial to not exceed a certain residence time (e.g., 2-3 seconds) to prevent temperature loss.

- Flow Optimization: Designing the gooseneck with smooth internal walls and avoiding sharp bends helps reduce turbulence and oxidation for better flow and surface quality.

Gooseneck Applications

Hot-chamber die casting, also known as gooseneck casting, is a process best suited for lower melting point alloys like zinc, magnesium, and some aluminum alloys.

It is used to produce a wide range of complex, high-volume parts for industries including automotive, consumer electronics, and hardware.

Haichen Gooseneck

Haichen’s gooseneck kettles are highly resistant to high temperature, wear, and corrosion, and the concentricity between the body and the gooseneck is extremely high to prevent eccentricity caused by punch jamming when the metal flows.

In terms of material selection, high-quality cast steel or forged steel is used, and some high-temperature resistant materials such as tungsten steel and silicon nitride ceramics are used.

It can match Haichen’s hot chamber die casting machine from 16 tons to 180 tons.

Gooseneck cost structure

- Material cost

- Maintenance & Replacemen

- Energy costs

Material cost

Gooseneck cost optimization,the gooseneck is the heart of a hot chamber die casting machine.

High-quality cast steel, forged steel or special alloys (such as tungsten steel, silicon nitride ceramics) account for about 40-50%.

Precision casting, heat treatment (such as quenching, nitriding) and surface treatment (such as plating) account for 20-30%.

Maintenance & Replacemen

The frequency of replacements due to high-temperature corrosion has a direct impact on costs.

The life of ordinary gooseneck is about 1.5 million molds, and the inferior materials may be as low as 1 million molds, but after optimization, it can reach more than 2 million molds.

Energy costs

Nozzle heating (400-500°C) accounts for 15-20% of the total energy consumption of the equipment.

Gooseneck Cost Optimization

- Material innovation and composite design

- Structural optimization and lightweighting

Material innovation and composite design

High-strength alloy substitution

By utilizing a composite structure of silicon nitride ceramics with temperature resistance exceeding 1200°C.

And tungsten steel, manufacturers have developed components that demonstrate 3-5 times greater longevity compared to traditional steel castings.

For example, the ceramic chamber is connected to the tungsten carbide barrel by a high-temperature adhesive to reduce metal residue and corrosion.

Gradient material technology

The inner layer consists of cemented carbide (such as WC-Co), while the outer layer comprises ductile steel, thereby achieving a balance between corrosion resistance and impact resistance.

Structural optimization and lightweighting

Fluid-Structure Interaction Simulation Optimization

After optimization, the weight of the gooseneck is reduced by 12%, and the manufacturing cost is reduced by 8%.

Modular design

The gooseneck is divided into detachable nozzle segments and connection segments, reducing the overall replacement cost (only the worn part needs to be replaced).