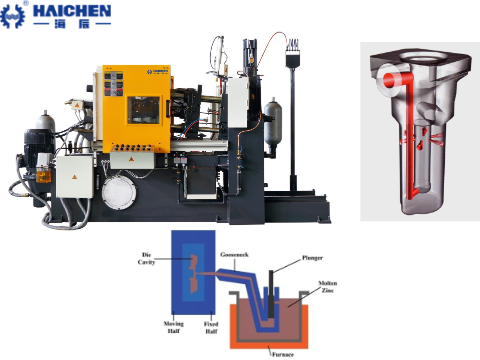

Gooseneck installation and commissioning in die casting involves precise alignment with the injection system, ensuring proper sealing and connection to the mold, and conducting thorough testing to verify functionality and optimize performance for consistent metal flow and part quality.

The gooseneck is a critical component in the die – casting process, responsible for transferring molten metal from the injection system to the mold cavity.

Proper installation and commissioning of the gooseneck are essential for ensuring efficient metal flow, consistent part quality, and overall production efficiency.

This article will provide detailed instructions and best practices to ensure a smooth and successful setup.

By understanding and following these guidelines, manufacturers can optimize their die – casting operations and achieve high – quality results.

Understanding the Gooseneck

- Function

- Components

Function

The gooseneck serves as a conduit for molten metal, ensuring a steady and controlled flow from the holding furnace to the injection chamber. Its design allows for precise control over the injection process, which is crucial for producing high – quality castings.

Components

The gooseneck typically consists of a flexible metal tube, often made from high – temperature – resistant materials, and a series of joints that allow for precise positioning and alignment. These components must be carefully selected and assembled to ensure optimal performance.

Gooseneck Installation Steps

- Preparation

- Mounting

- Connection

Preparation

Before installing the gooseneck, ensure that the die casting machine is powered off and all safety precautions are in place. Gather the necessary tools and materials, including the gooseneck assembly, mounting hardware, and any required seals.

Mounting

- Positioning: Place the gooseneck in the correct position on the machine, ensuring it is aligned with the holding furnace and injection chamber. Proper alignment is crucial for efficient metal transfer.

- Securing: Use the provided mounting hardware to securely attach the gooseneck to the machine. Ensure all connections are tight and properly sealed to prevent leaks.

Connection

- Furnace Connection: Connect the gooseneck to the holding furnace, ensuring a secure and leak – free connection. This step is critical for maintaining the integrity of the molten metal flow.

- Injection Chamber Connection: Connect the gooseneck to the injection chamber, ensuring proper alignment and secure attachment. This connection must be precise to ensure efficient injection.

Gooseneck Commissioning

- Initial Testing

- Calibration

- Final Testing

Initial Testing

- Leak Check: Conduct a thorough leak check to ensure all connections are secure and there are no leaks in the system. This can be done by pressurizing the system with inert gas and inspecting for any signs of leakage.

- Flow Test: Perform a flow test to ensure the molten metal flows smoothly and consistently through the gooseneck. Adjust the positioning and connections as needed to achieve optimal flow.

Calibration

- Flow Rate Adjustment: Adjust the flow rate of the molten metal to ensure it meets the specific requirements of the casting process. This may involve fine – tuning the position of the gooseneck or adjusting the injection parameters.

- Temperature Control: Maintain proper gooseneck insulation and control molten metal temperature within the specified range. This is crucial for consistent casting quality.

Final Testing

- Complete Cycle Test: Run the die casting machine through a complete cycle to ensure the gooseneck operates correctly throughout the entire process. Monitor the injection process to ensure there are no issues with metal flow or casting quality.

- Safety Check: Verify that the gooseneck is functioning safely and efficiently, with no risk of leaks or other hazards.

HAICHEN Gooseneck Solutions and Practice

HAICHEN has deep experience in designing, making, and setting up goosenecks for hot chamber die casting machines. Our solutions focus on stable, reliable, and long-lasting metal transfer, giving customers a ready-to-use, efficient experience.

- HAICHEN Gooseneck Design and Build Features

- HAICHEN Setup and Support System

- Case Study: Better Stability for Zinc Precision Parts

HAICHEN Gooseneck Design and Build Features

HAICHEN makes goosenecks from special alloy steel. This steel has very good strength at high heat and fights heat fatigue well. The inside channel is shaped using fluid flow software to make it very smooth. This reduces resistance when the metal flows and stops air from mixing in. Key joints use a special seal design. Every unit gets a high-pressure test before leaving our factory to prevent leaks. The modular design also allows fast change of wear parts like the nozzle, cutting maintenance time.

HAICHEN Setup and Support System

HAICHEN provides high-quality parts and also makes sure the system works well together.

- Pre-installation Check: Our engineers give a detailed list to check space and alignment based on the machine model and customer’s mold.

- Clear Installation Guide: We provide a guide with pictures and key steps. It shows correct positioning, how tight to fasten bolts, and how to seal.

- Parameter Tuning and Testing: After installation, our support team helps with first tests and setting the right process. We adjust keep-warm temperature, nozzle speed, and other settings. This makes the gooseneck, machine, mold, and metal work together best from the first try.

Case Study: Better Stability for Zinc Precision Parts

A maker of high-end zinc alloy hardware parts upgraded their line with HAICHEN hot chamber machines. They paid special attention to the gooseneck.

- Challenge: Their old gooseneck often made cold spots, causing flow marks on small parts. The seals wore out fast, needing replacement every two months.

- HAICHEN Solution: We provided a HAICHEN gooseneck with a special coated inside wall. We also improved the heating around it for even temperature. During setup, we carefully aligned the nozzle with the mold gate, keeping the error under 0.1mm.

- Result: With the new gooseneck, cold spot problems stopped. Part surface quality got much better. The seal system stayed tight with no leaks even after six months of use. The customer’s planned maintenance intervals became longer, and overall production efficiency rose by about 15%.

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we specialize in manufacturing high – quality die casting machines equipped with advanced features and reliable components. Our precision-engineered machines deliver efficient and safe operation, consistently producing parts that exceed industry standards. Whether you are installing a new gooseneck or upgrading your existing equipment, HAICHEN has the solutions to meet your needs.

Proper installation and commissioning of the gooseneck are essential for achieving efficient and high – quality die casting production. Follow this article’s steps to correctly install your gooseneck and optimize its performance.