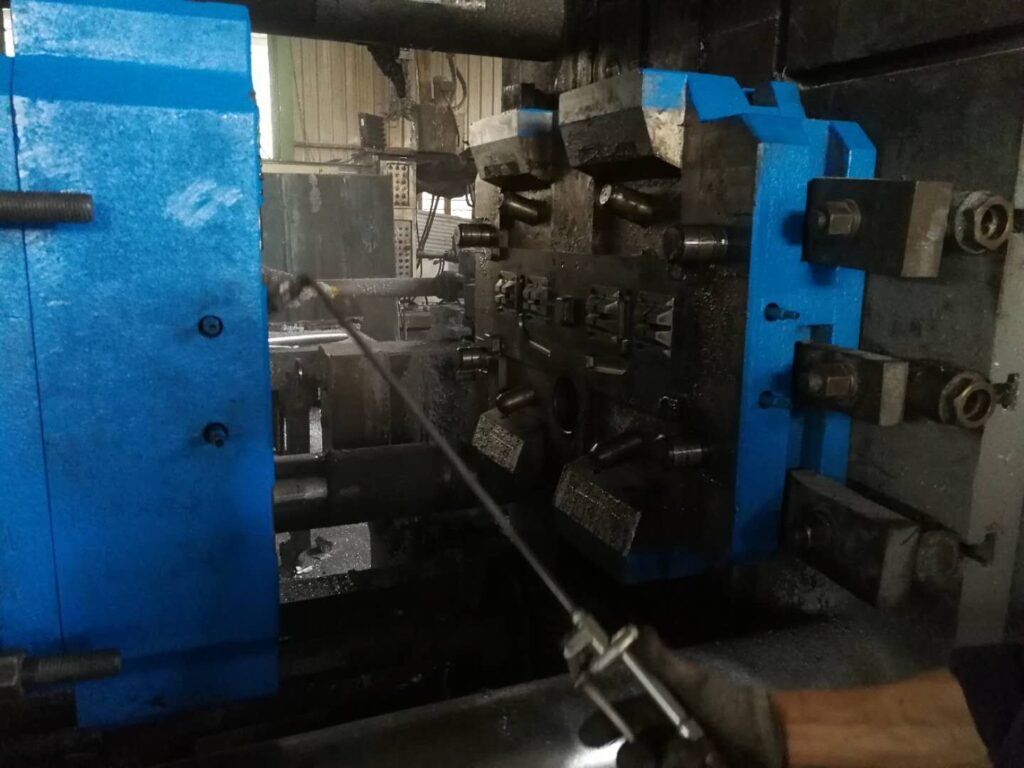

How Mold Temperature Controller Work : It precisely regulates mold temperature via coolant circulation to ensure consistent casting quality .

Mold temperature control must be done to exact specification as it is extremely important in achieving quality part production using die casting.

A machine that seeks to maintain even heating during the die casting process is known as a mold temperature controller. It is designed to automate the heating of the mold and to maintain a set mark throughout the cycle plan.

This document will discuss the function of controllers to the process of die casting and why temperature control is of utmost importance.

The Value of Controlling a Molds Temperature

- Even Repeative Quality

- Minimum Possible Faults

- Faster Cycle Counts

Even Repeative Quality

Industry set standards have to be met in terms of precise measurements and contour shape. Guaranteeing proper temperature setting in pre-defined intervals ensures that the parts produced will, albeit sometimes uniformly replicated. This is step is necessary towards achieving zero defect production with close-tolerance advanced feature technology.

Minimum Possible Faults

Lacking inspection or low supervision increases defects which can randomly occur in gap measurement, molding, and processing such as porous space, reduction in volume, and formation of bends. The above mentioned factors are greatly reduced due to accurate temperature management when the mold is retained within preset boundaries.

Faster Cycle Counts

The ability to produce more within a period lowers the cost per unit. climbing the temperature reduces cycle time. This saves time with every injection. Keeping the internal environment of the mold free of thermal variations leads to stable temperature which boosts the production rate.

Basic Principles of Mold Temperature Controllers

- Spot Checking

- Mold Temperature Controllers (MTCs)

- Control algorithms

- User Interface

Mold Temperature Controllers (MTCs)

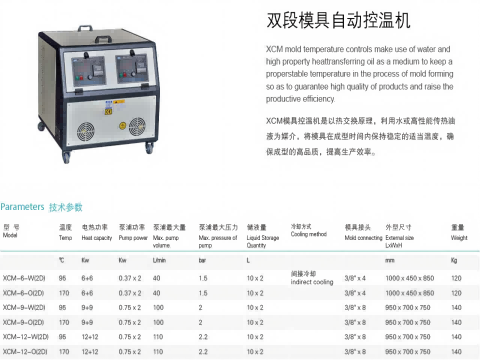

MTCs have a temperature management system that allows the mold temperature to be raise or lowered to the desired temperatures. The heat can be provide by heating elements while the cooling can be do by cooling channels or heat exchangers. The controllers rely on sensor data to modulate these systems.

Control algorithms

Technologically advanced control algorithms and artificial intelligence embedded in the MTC make sure that the optimum temperature required is maintaine by implementing changing process parameters such as injection speed, physical characteristics of the material being use, and even external factors like environmental conditions.

User Interface MTC

comes equipped with a user interface that is specially designed for each operator to monitor and set the desired temperature of the mold.Set and monitored real time feedback, changes can be made as required.

Practical Applications and Benefits of Mold Temperature Controllers

- Automotive Industry

- Electronics Industry

Automotive Industry

Mold temperature controllers are precise components like engine parts, transmission housings, and structural components. All these parts requires absolute precision and indredible structural integrity. Very precise temperature regulation is the answer.

Electronics Industry

Mold temperature controllers are crucial for the production of high precision enclosures and connectors. Quite often they feature complex geometries that have very tight tolerances and use gaps for proper functions and fitting.

Practical Applications and Benefits of Mold Temperature Controllers

In different industries, mold temperature controllers are vital for producing high-quality, complex parts.

- Automotive Manufacturing

- Electronics Industry

Automotive Manufacturing

When making key parts like engine blocks or transmission housings, precise temperature control is necessary. It ensures dimensional stability, mechanical strength, and part density. This directly affects the part’s performance and safety.

Electronics Industry

For electronic housings and connectors with complex shapes, thin walls, and very tight tolerances, accurate temperature control helps prevent defects like flash and incomplete filling. It ensures good product appearance, assembly fit, and heat dissipation.

HAICHEN: Your Partner in Die Casting Solutions

At HAICHEN, our passion lies in crafting die casting machines that exhibit precision and reliability in their operation. To maintain production quality and efficiency, all our machines outfitte with advanced mold temperature controllers. Regardless of whether you are producing automotive parts, aerospace components, or other high-precision products, HAICHEN has the tools and experience to help accomplish your production goals.

Why Choose HAICHEN?

- Advanced Technology: Our die casting machines guarantee the production of high-quality components through the implementation of cutting-edge control systems, and advanced precision parts, including integration into our vertical die casting systems.

- Custom Solutions: For specific requirements, we provide custom configurations of our machines including the capability of controlling mold temperature.

- Quality and Reliability: HAICHEN machines manufactured to provide the greatest level of quality and reliability, maintaining consistent productivity while averting unscheduled downtimes.

- Comprehensive Support: Beyond customer satisfaction, HAICHEN dedicated to providing extensive after-sales support, in addition to technical and maintenance assistance.

HAICHEN Die Casting Solutions: Integrating Smart Temperature Control

HAICHEN die casting machines come with high-performance mold temperature controllers built in. This ensures stable and efficient production. We use a real case from an auto parts maker to show how HAICHEN solves specific temperature control challenges.

- Customer Challenge & HAICHEN Solution

- HAICHEN’s Targeted Measures

- Results Achieved

Customer Challenge & HAICHEN Solution

The customer made large aluminum structural parts. They faced serious shrinkage porosity in hot spots, low yield, and long cycle times. HAICHEN engineers found that large temperature differences across the mold were the main cause.

HAICHEN’s Targeted Measures

HAICHEN provided a multi-zone, independently controlled mold temperature system linked with the die casting machine’s main control. The solution used separate cooling circuits for different mold areas. It applied precise higher-temperature control to hot spots and stronger cooling to non-critical areas.

Results Achieved

After implementation, the mold’s overall temperature uniformity improved by over 60%. The shrinkage defect rate dropped to below 0.5%. At the same time, better cooling efficiency cut the single-part cycle time by about 15%. This significantly increased the customer’s output and economic benefits.

Mold Temperature Control Innovations and Trends for the Future

- Smart Control Systems

- Energy Efficiency

Smart Control Systems

- Integration into IoT: In the future, mold temperature controllers will most likely have the ability to interface with the Internet of Things (IoT), enabling remote temperature adjustment of the mold. This capability will streamline the optimization of production processes and boost efficiency on a larger scale.

- Predictive Maintenance: Advanced analytics and machine learning algorithms will used to predict potential issues with the mold temperature control system. This will allow for proactive maintenance, reducing downtime and improving the reliability of the production process.

Energy Efficiency

- Energy Recovery Systems: New developments in mold temperature control will focus on energy recovery systems that can capture and reuse heat from the cooling process. This will not only reduce energy consumption but also contribute to a more sustainable manufacturing process.

- Adaptive Control: Adaptive control systems will adjust the mold temperature in real-time based on the specific requirements of the part being produced. This will ensure optimal conditions for each production run, further enhancing part quality and consistency.

Mold temperature controllers play a vital role in the die casting process by ensuring consistent and optimal mold temperature. Mold Temperature Controller Work achieves this through advanced thermal regulation systems that maintain precision ±1°C stability for defect-free production. By maintaining precise temperature control, manufacturers can produce high-quality parts with fewer defects and higher production efficiency.