Here are the energy saving solution of cooling chiller in die casting.

- Chiller Size and Selection

- Adjust Smart Temperature Control

- Energy Recovery System

- Cooling Tower Operation Efficiency

- Improvements in efficiency of chilled water systems

- Advanced Cooling Strategies

Energy saving solution of cooling chiller in die casting

Chiller Size and Selection

As a best practice, employ variable speed or inverter driven chillers that meet the set cooling load requirements. There should be no oversized chillers as they have low efficiency when part loaded. It is best to consider high-efficiency chillers with a COP (Coefficient of Performance) rating.

Adjust Smart Temperature Control

Measures Temperatures should be maintained using controllers such as PID (Proportional-Integral-Derivative) to ensure a specific cooling temperature is not exceeded. Dynamically modify setpoints to align with process/requested parameters to prevent overcooling.

Energy Recovery System

Waste heat reduction achieved from chillers can be repurposed for preheating molten metal, space heating or other processes. Heat exchangers should be set in place for the transfer of surplus heat to other systems.

Cooling Tower Operation Efficiency

For cooling tower pacing, the fan speed should be set using VFD (Variable Frequency Drives). Water treatment should be observed at all times to avoid scaling and fouling which impacts cooling heat transfer efficiency, reducing load capacity. In cooler regions, free cooling should be used adiabatically to reduce the workload on the chillers.

Improvements in efficiency of chilled water systems

With partial loads, energy use will be reduced by using variable speed pumps. Enhance insulation in pipes, minimize pressure drops across the system. Move the demand for cooling to off peak periods using Thermal Energy Storage (TES). Regular observation, maintenance and adjustment of TBs as well as checking for leaks during early stages helps to clean both the condenser and evaporator coils

Advanced Cooling Strategies

- Phase-change materials (PCMs) can be used for temporary cooling needs.

- Hybrid cooling systems combining air and water cooling for optimal efficiency.

What is the cooling system in die casting?

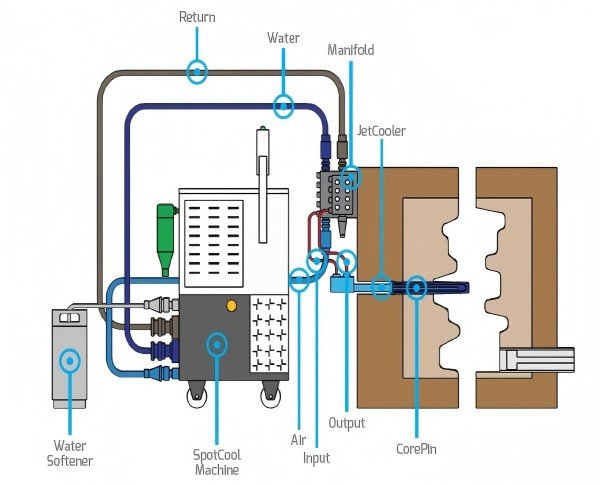

The die casting cooling system is a vital component of the die casting process. Its main purpose is to control the mold temperature and ensure that the molten metal can be cooled quickly and evenly, so as to achieve high-quality casting production. The design and efficiency of the cooling system directly affect the production speed, mold life and product quality.

What is Cooling System in Die Casting Mold?

The cooling system in a die casting mold is a network of channels that remove heat from the mold during the die casting process. The cooling system helps control the temperature of the mold and the molten metal, which is important for producing high-quality parts and reducing production cycle times.

Cooling system in a die casting mold usually consists of a series of channels that are machined or drilled into the mold. These channels can be designed to follow the contours of the mold or placed in specific locations where heat buildup is most likely to occur.

How does a cooling chiller work in die casting?

Die Casting Coolers are uniquely designed coolers that effectively remove heat from the die casting process system by circulating a heat transfer fluid (water or oil) through the die to preheat and maintain the die at a set temperature point.

What are cooling types in die casting?

- water cooling

- oil cooling

- spray cooling

Water Cooling:

The most prevalent cooling method is this one. It involves absorbing heat from the mold surface by circulating water through the mold’s cooling channels and using the water as a coolant. Even though this method is relatively efficient, it necessitates constant upkeep to avoid clogging.

Oil Cooling:

This is used for molds that need uniform high temperature control. It uses a high temperature oil ( e.g. thermal oil ) as the cooling medium. One strong point of oil cooling is its good thermal stability and reduced thermal stress. Oil cooling is more complex to maintain and can pose a fire risk.

Spray cooling:

Generally applicable for large aluminum parts or molds that need to cool off quickly, this technique involves the rapid de/reduction of the mold’s temperature by spraying fine water or other cooling agents onto its surface.

Haichen die casting solution supplier

Haichen is a die casting machine factory in China, mainly supplying cold chamber die casting machine and hot chamber die casting machine. Besides, we also supply the corresponding die casting auxiliary machines, including cold water, robots and so on. If there is any need, please feel free to contact us.

The cooling water chiller ensures that the mold maintains an approximate temperature during the die casting process through an efficient cooling mechanism, thereby optimizing product quality, production cycle and extending mold life. This process requires a combination of advanced design and maintenance strategies to achieve the best production results.