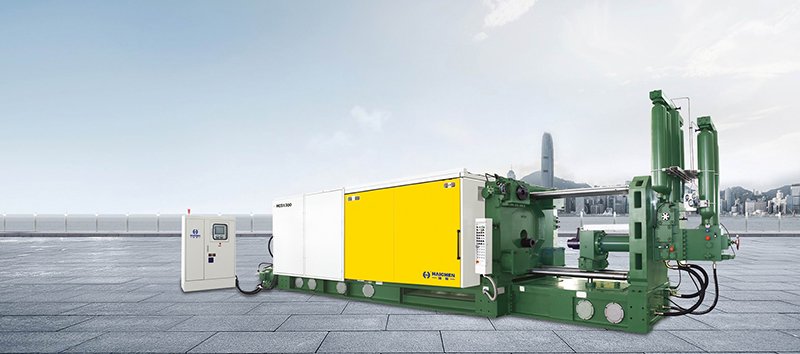

Release agent mixer manufacturers include L.K. Group and Yizumi in China.

The main purpose of the die-casting release agent mixer is to evenly mix the various components of the release agent (such as silicone oil, wax, surfactant, etc.) to ensure its stability and performance, thereby forming an effective protective film during the die-casting process, facilitating the demolding of castings and extending the life of the mold.

The mixer fully blends the different components through stirring, emulsification and other steps. For example, the water-based release agent needs to evenly disperse the silicone oil and the modified components in water.

Therefore, finding the right Die casting release agent mixer manufacturer is extremely important for your die casting industry production.

Applications of Die Casting Release Agents

- Haichen’s superior mold lubrication provides reliable and consistent demolding results

- Easily dilute to meet your specific needs

- Enhance the flow of metal in the mold

- Further reduce porosity and improve part quality

Water-based and water-free release agents

Water-based release agent usage

In non-ferrous die casting, a distinction is made between the use of waterless and water-based release agents.

Waterless release agents are mainly for hot-chamber zinc die casting.

This is because the die temperatures for zinc die casting are usually between 80°C and 180°C, and the energy input for zinc alloys is lower than for aluminum-silicon or magnesium alloys, since the melting point of zinc alloys is around 400°C.

Application fields of water machine release agent

Due to the advent of new commercial oils, waterless release agents are also widely used in magnesium and aluminum die casting – the benefits are obvious: the lower spraying volume leads to less waste to be disposed of, and since there is no cooling effect of waterless release agents, tool steels are not subjected to the thermal stresses typical of water-based release agents, which can cause premature aging or damage to hot-formed steels.

In addition, the advantage of using waterless release agents for magnesium alloys is that the required thermal energy supply is significantly reduced. However, when using waterless release agents, appropriate extraction systems need to be installed above the die casting machine to prevent the generated aerosols and vapors from escaping into the foundry.

After more design iterations Haichen water-based mold release agents can achieve wetting at mold temperatures from about 150°C to more than 300°C. So-called “high-temperature mold release agents” are able to wet and form a mold release film at extremely high temperatures. The thermal shock stress they generate is significantly lower than in the past.

In addition to the casting alloy, need to consider many more details of die casting production t before choosing the right release agent mixer.

These include: the draft angle of the die, the surface of the part to be manufactured, the porosity level that must be met, whether the die casting is used as a safety component, whether the surface of the part is finely processed (such as galvanized or painted), whether the die casting is welded or glued (see “Die Casting Welding”), whether the structural component is cast from a wrought alloy and has long flow channels, etc.

The application of the release agent must also be considered:

- How can the release agent be mixed correctly using a proportioning machine?

- Is the water quality suitable for diluting the release agent?

- In which system will the release agent be diluted and delivered to the individual die casting machines?

- What spraying equipment is used to apply the release agent?

- What residues will the release agent leave on the supply system, casting tools and, most importantly, the die casting?

In general, the criteria are extremely complex and often even contradictory.

The selection of a release agent should therefore always be carried out together with the well-trained and experienced application engineers of the manufacturer of the release agent mixing machine.

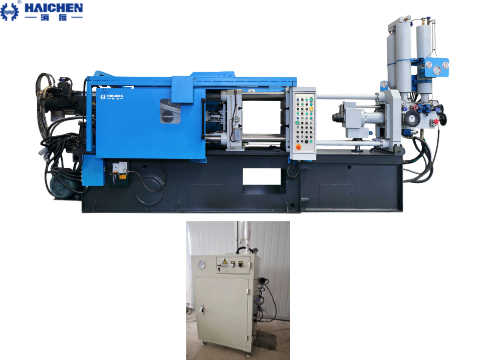

Haichen die casting machine release agent mixer manufacturer

As experienced producers, we sincerely recommend this.

From the perspective of economic efficiency, the price of the release agent mixer itself is not the most important criterion and should not be the only aspect that a company considers – cheap products may lead to productivity and efficiency losses in die casting, reworking and subsequent refining, which is not worth the loss.

After many years of practice by Haichen, the mixing process can also adjust the concentration of the release agent, optimize the spraying effect, and avoid the film formation problem caused by uneven temperature on the mold surface.

Together with efficient mixing technology (such as colloid mill), we can improve the high temperature stability and lubricity of the release agent .And reduce the risk of adhesion of aluminum die-casting products.

FAQs of Die casting Release Agent Automatic Mixer:

Q: What is the power source for this automatic mixer?

A: The power source for this unit is electricity.

Q: What is the weight range available for this product?

A: The weight of the unit can vary as per available kilograms (kg).

Q: What color is the Die casting Release Agent mixer?

A: The unit comes in a sleek white and black color combination.

Q: What are the usage/applications of this unit?

A: This unit is designed for industrial usage and applications.

Q: Does this unit come with a warranty?

A: Yes, this unit comes with a warranty for added peace of mind.

Call Haichen for more die casting technical support.