The effective volume of the crucible(zinc) of a die-casting machine refers to the maximum amount of liquid metal alloy that the crucible can hold in actual production.

How much zinc we can melt in the crucible is the effective volume of the crucible(zinc). ?

The effective capacity of the crucible of a die-casting machine of different models and types is different. And it is effective for hot chamber die casting machine.

How to calculate the effective volume of the crucible(zinc)?

Calculating the effective capacity of a hot chamber die casting crucible usually involves the following 5steps:

- Determine the physical dimensions of the crucible

- Consider metal type and density

- Calculate the volume of the crucible

- Convert volume to mass

- Consider actual production needs

Determine the physical dimensions of the crucible

The dimensions of the crucible include diameter, height, etc. These parameters directly affect its capacity.

Consider metal type and density

Different metals have different densities. So you need to consider the type of metal when calculating capacity. For example, zinc has a density of about 7.14 g/cm³, while aluminum has a density of about 2.7 g/cm³.

Calculate the volume of the crucible

Based on the physical dimensions of the crucible (such as diameter and height), calculate its volume. The volume can be calculated using the formula for the volume of a cylinder: V=πr2h, r is the radius, h is the height

Convert volume to mass

Multiply the calculated volume by the density of the metal to get the effective capacity of the crucible. For example, if the volume of the crucible is, V cubic meters, the density of the metal is ρ, ρ kg/cubic meter Effective capacity C=V×ρ

Consider actual production needs

Select a crucible of appropriate capacity based on actual production needs and the parameters of the die-casting machine. For example, it is mentioned that the capacity of the crucible should be able to meet the production batch size and frequency.

Calculating the effective capacity of the crucible in a hot chamber die-casting machine, requires comprehensive consideration of the physical dimensions, metal type and density, and actual production requirements of the crucible. Through these steps, the effective capacity of the crucible can be accurately calculated.

Haichen die casting machine technical parameters of the effective volume of the crucible(zinc)

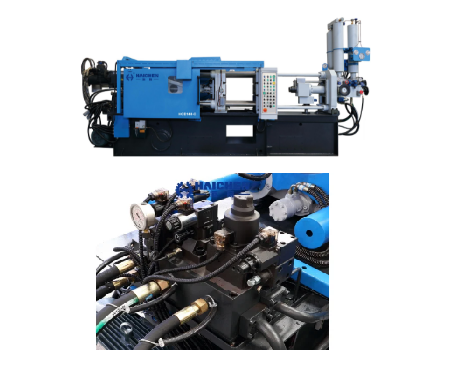

Die casting machine- Haichen

Haichen machinery produces high-pressure die casting machines. It includes both cold chamber die casting machines and hot chamber die casting machines. They have highly durable and precise features.

- Hot-chamber die-casting machine

- Clamping mechanism

- Injection mechanism

- Hydraulic transmission system

- Electrical control system

Auxiliary systems

The hot-chamber die-casting machine is a highly efficient casting apparatus specifically designed for casting low-melting-point alloys such as zinc, magnesium, and lead alloys.

Its core principle involves injecting molten metal into the mould cavity under pressure, where it cools and solidifies to form precision castings.

The furnace chamber during the die-casting process

Mould-Closing Mechanism

The mould-closing mechanism is responsible for opening, closing, and locking the mould. It comprises the fixed base plate, moving base plate, tie rods, hydraulic cylinders, and other components.

Modern models predominantly employ hydraulic or hydraulic-mechanical structures, with clamping forces reaching several thousand kilonewtons (kN).

Its function is to ensure stable mould closure during high-pressure injection, preventing molten metal leakage.

Injection Unit

The injection unit comprises the pressure chamber, ram, nozzle, and associated components.

The pressure chamber is directly immersed in the molten metal within the furnace.

Molten metal is propelled at high velocity by the vertically moving injection cylinder to fill the mould cavity.

Velocities may reach 5–8 metres per second, with pressures up to 40–150 megapascals, enabling the formation of thin-walled, complex components.

Optimised injection systems (e.g., dual-speed control) and nozzle heating devices enhance filling efficiency and casting surface quality.

Hydraulic Transmission System

Employing multi-stage pressure control and accumulator technology, it facilitates smooth transitions between actions such as mould closing, injection, and ejection.

System pressure typically ranges from 10-21 MPa, incorporating low-noise high/low-pressure dual pumps for energy conservation.

Die-casting Injection Unit Maintenance

Electrical Control System

Integrated PLC and touchscreen interface supporting multilingual operation and parameter presets (e.g., injection speed, holding time).

Haichen die-casting machines incorporate real-time monitoring modules to record production data and issue alerts for anomalies.

Auxiliary Systems

Furnace: Fully automatic combustion furnace or electrically heated crucible, capacity 50–500 dm³, with temperature control accuracy of ±5°C.

Cooling/Lubrication System: Mould temperature regulated via water-cooling or oil-cooling, while a centralised lubrication system minimises wear on critical components.

In summary, the effective volume of the crucible(zinc) for the die casting machine should be selected based on the actual production needs and the metal capacity of the furnace to ensure production efficiency and continuity.