Advantages of cast aluminum:Cast Aluminum can be used in parts of automotive and aerospace machinery as it is lightweight and easy to carry compared to steel. Additionally, it has good resistance to corrosion and can be used in consumer electronics due to its good thermal and electrical conductivity.

Due to its benefits, Cast Aluminum is widely use in the manufacturing industry. Businesses can save the money and resources while producing a wider variety of goods.

Manufacturers aiming to increase the durability and efficiency of their parts need to understand the benefits which Cast Aluminum can provide properly.

In this piece, we will analyze the advantages of Cast Aluminum, how it improves die casting and, in particular, its productivity and quality.

Other than that, we will look into specific instances of how Cast Aluminum is used in different lines of production for optimal results.

Advantages of cast aluminum

Cast aluminum offers a balance of strength, weight, and cost-effectiveness that makes it ideal for applications ranging from automotive parts to consumer electronics.

- Lightweight and Strong

- Corrosion Resistance

- High Thermal Conductivity

- Design Flexibility

- Cost-Effective

- Recyclability

Lightweight and Strong

Due to its lightweight, Cast Aluminum is a lot easier to carry as compared to steel. It is also more durable than other materials. For the automotive and aerospace industry, having fuels that can be more efficient is a lot more preferable and having stronger and lightweight parts improves the performance as well.

Corrosion Resistance

Cast aluminum has resistance to corrosion which is advantageous for products that face harsh Other environments. The corrosion resistance property of aluminum makes it suitable for outdoor use and for components that encounter moisture or chemicals. The natural oxide layer that forms on the surface closed the aluminum protects the aluminum from corrosion increasing the lifespan of the product.

High Thermal Conductivity

A plane of aluminum has high thermal conductivity which is advantageous for use in areas where heat transfer is needed. This property helps in the manufacture of heat sinks, and for the engine parts and other components for which thermal control is critical. The ability to quickly dissipate heat helps maintain optimal temperature and enhances the performance and reliability of items.

Design Flexibility

The casting technique enables features of high designable obtainable. Designable obtainable complex Sofas and sophisticated sophisticated segments can be achieved by cast aluminum. From the aviation and automobile engine parts to elaborate parts housings for consume electronics, cast aluminum can be tailored to fit specific design needs. This designable obtainable also makes it possible to combine and assemble several components in one casting, which helps in saving time and cost in the payments of architecture.

Cost-Effective

Cast aluminum provides a case in point where a material excels in cost-efficiency, particularly in high-volume manufacturing operations. In our experience, the tooling expenditures associated with aluminum casting are more economical than other manufacturing techniques. Moreover, the aluminum itself is accessible and affordable. Furthermore, the ability of the process to lower production expenditure by enhancing the speed and efficiency of parts production in bulk is beneficial.

Recyclability

The environmental advantages of cast aluminum stems from the fact that it can be recycled, and recycled aluminum can maintain its properties and be reused over and over again with minimal degradation. The aluminum industry aluminum recycling is a closed-loop process that dramatically reduces the need for resource extraction. This makes it easier to practice sustainable manufacturing by reducing waste and conserving materials.

Technical Challenges and Solutions

- Porosity: In die casting, rapid filling of the mold can easily trap gas and negatively impact airtighness.

- → Solutions: Vacuum die casting, localized extrusion techniques, optimized mold venting.

- Elongation Limitation: The maximum elongation of die castings is under 2% and sand castings can achieve 8%.

- → Solutions: Al-Si-Mg high-toughness alloys; semi-solid die casting to lower shrinkage defects.

- Heat treatment Limitations: Blistering of die castings is a common problem with conventional T6 treatments.

- → Solutions: low-pressure casting with heat treatment, micro-arc oxidation surface strengthening.

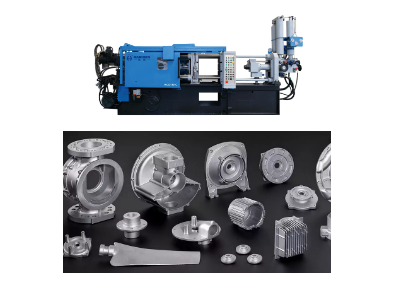

HAICHEN: Die Casting Machine Manufacturer

HAICHEN remains a trusted manufacturer when it comes to High-pressure die casting machines and industrial machinery. Our machines incorporate advanced industrial technology for ease of use and durability.

We offers a comprehensive range of die casting machines, from hot chamber to cold chamber variants. As a leader in the industry, HAICHEN offers total post-sale service including technical assistance, spare part provisions, as well as comprehensive training to maximize the customers return on investment.

Haichen Aluminum Products: Advantages and Application Practices

Leveraging advanced die-casting technology and extensive industry experience, Haichen transforms the superior properties of cast aluminum alloys into the core competitiveness of its high-performance end products. Below are some of Haichen’s representative aluminum products and their advantages:

High-Performance Cookware (Taking a 280×70 aluminum deep frying pan as an example)

Product Advantages:

- Extreme Heat Conductivity and Uniform Heating: Utilizing the high thermal conductivity of aluminum alloys, Haichen’s precision temperature-controlled die-casting process ensures a progressive wall thickness design from the bottom (4mm) to the side walls (2.8mm), achieving rapid heat conduction and uniform distribution, avoiding hot spots.

- Lightweight and Structural Strength: Compared to traditional iron pans, it reduces weight by over 60%, significantly improving the user experience. Simultaneously, optimized alloy formulas and die-casting parameters guarantee the necessary mechanical strength and durability of the pan body.

- Healthy Surface and Easy Cleaning: After die-casting, a special surface treatment creates a dense, smooth, uncoated, healthy cooking surface, combining excellent corrosion resistance and easy cleaning properties.

Haichen’s technological contributions: Utilizing the HCD series cold chamber die-casting machine, coupled with a multi-stage intelligent injection and precise mold temperature control system, perfect filling and rapid solidification of complex deep cavity structures are achieved, with a daily production capacity exceeding 1500 pieces and a stable yield rate above 98.5%.

Engineering-grade structural components (taking road studs as an example)

Product advantages:

- Superior strength and impact resistance: Using high-silicon (Si) aluminum alloy, Haichen’s die-casting process achieves a dense and uniform grain structure, enabling the product to withstand extreme impact loads from frequent vehicle traffic and exhibiting excellent fatigue resistance.

- Excellent weather resistance and corrosion resistance: Thanks to the inherent oxide protective layer of the aluminum alloy and Haichen’s optional surface strengthening processes (such as anodizing), the road studs maintain their functionality for extended periods in harsh outdoor environments such as rain, snow, and de-icing salt, extending maintenance cycles.

- Economic benefits and convenient installation: Lightweight design reduces transportation and installation costs, integrated die-casting reduces assembly steps, and the unique reflective design module can be efficiently integrated through embedded molding.

Haichen’s technological contributions: To address the wear-resistant requirements of road spikes, a special nitriding treatment is applied to the mold cavity, significantly extending mold life. A stable high-speed injection process ensures smooth flow of molten metal during rapid filling, eliminating defects such as cold shuts.

These industries benefit from aluminum casting due to its economic advantages. Furthermore, the aluminum’s lightweight, strength, high corrosion resistance, thermal conductivity, ease of design and machining, lower cost, and efficiently recyclable. Since the advantages of aluminum casting are high, it can be used in a range of industries.