Application of metallic lightweight materials such as aluminum and magnesium alloys: Widely used in the automotive, aerospace, and consumer electronics industries to reduce weight, improve fuel efficiency, and enhance performance while maintaining structural integrity.

In modern manufacturing, the demand for lightweight materials has surged across various industries, driven by the need for improved fuel efficiency, reduced environmental impact, and enhanced performance.

Metallic lightweight materials, such as aluminum and magnesium alloys, have become essential in achieving these goals.

These materials offer a unique combination of high strength, low density, and excellent corrosion resistance, making them ideal for applications in automotive, aerospace, and consumer electronics.

Automotive Industry

The automotive sector is one of the largest consumers of metallic lightweight materials. The shift towards electric vehicles (EVs) has further intensified the need for lightweight components to extend battery range and improve energy efficiency.

Aluminum alloys, with their high strength-to-weight ratio, are widely used in engine blocks, wheels, and body panels.

Magnesium alloys, being even lighter, are increasingly employed in interior components such as steering wheels, seat frames, and instrument panels.

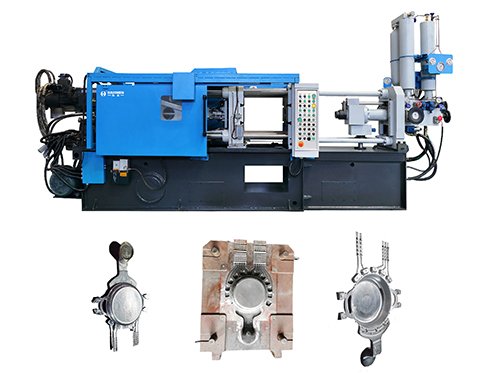

HAICHEN, a leading die-casting machine manufacturer, has been at the forefront of innovation in this field. Our advanced die-casting machines are specifically designed to handle the complexities of producing lightweight metallic components with high precision and consistency.

HAICHEN’s technology ensures that automotive parts made from aluminum and magnesium alloys meet the stringent quality standards required for modern vehicles.

Haichen Die Casting Application Example

Haichen provided a high-efficiency die casting solution for a well-known automotive parts manufacturer, using aluminum alloy to produce complex engine mounts. Employing a “one-to-one” mold design ensured the density and strength of the internal structure of individual parts, achieving a 30% weight reduction.

Aerospace Industry

The aerospace industry has long recognized the benefits of metallic lightweight materials. Aircraft manufacturers strive to reduce the weight of their aircraft to enhance fuel efficiency and extend range.

Titanium alloys, known for their exceptional strength and corrosion resistance, use in critical components such as engine parts and landing gear.

Aluminum and magnesium alloys also widely use in aircraft interiors and secondary structures.

Consumer Electronics

The consumer electronics industry is another major beneficiary of metallic lightweight materials. Devices such as smartphones, laptops, and tablets require materials that are not only lightweight but also durable and aesthetically pleasing.

Aluminum and magnesium alloys are ideal for this purpose, providing a sleek and robust casing for electronic devices.

HAICHEN’s die-casting solutions are tailored to meet the high-volume and high-precision demands of the consumer electronics market.

Our machines are designed to produce intricate and lightweight components with excellent surface finish and dimensional accuracy. This ensures that electronic devices are not only functional but also visually appealing.

Other Industrial and Consumer Products

Besides the major industries mentioned above, light metal alloys are also widely used in other fields. For example, zinc alloys, due to their excellent casting properties and surface treatment capabilities, are often used to manufacture high-end hardware, locks, and medals.

Haichen Die Casting Application Examples:

Haichen once produced official commemorative medals for a major international sporting event. Utilizing zinc alloy die casting and employing a “1-to-4” mold design for efficient production, coupled with sophisticated electroplating and enamel processes, the final product boasted exquisite details and outstanding texture, earning high praise from the organizers.

In the industrial sector, Haichen also produced aluminum alloy industrial cookware bodies and heat dissipation base plates for clients. Employing a “1-to-1” large-cavity mold ensured uniform wall thickness and excellent thermal conductivity in the products.

Advantages of Metallic Lightweight Materials

The use of metallic lightweight materials offers several key advantages across various industries:

- Weight Reduction: Reducing the overall weight of vehicles and aircraft leads to significant fuel savings and reduced emissions.

- Improved Performance: Lighter components enhance the agility and efficiency of vehicles and aircraft.

- Durability: Materials like aluminum and magnesium alloys offer excellent corrosion resistance and long service life.

- Recyclability: Many metallic lightweight materials are highly recyclable, contributing to sustainable manufacturing practices.

Future Outlook

The future of metallic lightweight materials looks promising as industries continue to seek innovative ways to reduce weight and improve efficiency. Advances in material science and manufacturing technology will further enhance the performance and application scope of these materials. HAICHEN, with its cutting-edge die-casting machines, supports this growth and contributes to the development of next-generation lightweight products.

Metallic lightweight materials are playing a crucial role in modern manufacturing, driven by their unique combination of properties. With the support of advanced manufacturing solutions from companies like HAICHEN, industries can continue to push the boundaries of what is possible, creating lighter, stronger, and more efficient products for a sustainable future.