Die casting and forging applications include in the automotive industry, aerospace, industrial machinery and so on.

Die Casting and Forging complement each other in industrial manufacturing: the former is good at high efficiency and complex molding, while the latter focuses on strength and durability.

When choosing, you need to consider the function of the part, the material properties and cost-effectiveness. With the advancement of technology, the integrated application of the die casting and forging in the field of lightweight and high performance (such as semi-solid technology) will promote innovation in the manufacturing industry.

- Main application areas of Die Casting

- Main Application Fields of Forging

- Construction and infrastructure

- Selection principles of Die cating and Forging

Main application areas of Die Casting

Automotive industry

Engine and transmission system: such as engine block and gearbox housing, using the lightweight advantages of aluminum die casting to improve fuel efficiency.

- Structural parts: door frames and suspension parts, reducing assembly processes through high-precision molding.

- Main components/applications: Engine housing, cylinder head, gearbox housing, steering gear, brake calipers, wheels, body structural parts, decorative parts

- Die casting features: High-pressure injection molding can form complex, thin-walled structures in one go, with light weight and high dimensional accuracy

Consumer electronics

Housing and radiator: metal housings of smartphones and laptops, taking into account both aesthetics and heat dissipation like aluminum radiator

- Connectors: highly conductive zinc die castings are used for USB interfaces and circuit board fixtures.

- Main components/applications: Mobile phone, notebook, tablet, game console casing, radiator.

- Die casting features: Where high surface finish and complex internal channels are required, die casting can be completed in one go, reducing assembly costs.

Aerospace

Lightweight structural parts: aircraft engine blades and fuselage brackets, using magnesium alloy die casting to reduce weight.

- High temperature resistant parts: turbine housings are die-casted with special alloys to achieve high temperature stability.

- Main components/applications: Engine hood, brackets, fuselage structural parts, deflectors, ejection device parts.

- Die casting feature: Magnesium and aluminum alloy die-castings are both lightweight and high-strength, meeting the strict strength-to-weight ratio requirements of aviation.

Industrial machinery

- Hydraulic system parts: pump bodies and valves, using the sealing and pressure resistance of die casting.

- Tools and equipment: power tool housings, improving durability and insulation performance.

Other fields

- Lighting equipment: LED heat dissipation bases are optimized through aluminum die casting for thermal management.

- Medical equipment: surgical instrument housings, meeting surface finish requirements in sterile environments.

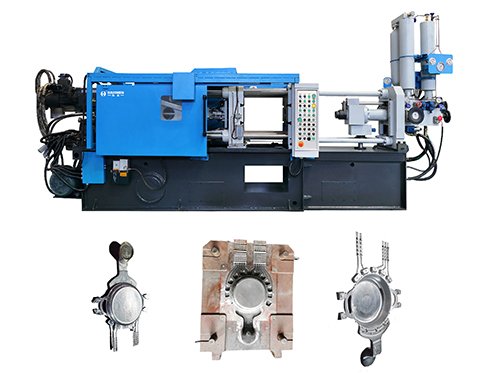

Haichen has established a prominent force in the die-casting industry, renowned for providing technologically advanced solutions. Specializing in both hot and cold chamber die-casting machines. For examples, aluminum pan die casting, aluminium radiator die casting, zinc medal die casting, zinc pipe couping die casting.

Haichen die casting technique is engineered for high precision, exceptional reliability, and superior efficiency in producing complex metal components. By integrating innovative features and intelligent control systems, they achieve enhanced productivity and reduced operating costs. Committed to performance and durability, Haichen Machinery is the trusted partner for foundries seeking to excel in the competitive and demanding field of die-casting production.

Main Application Fields of Forging

- Die casting and forging applications: Aerospace

- Automotive industry

- Die casting and forging applications:Energy and heavy industry

Die casting and forging applications: Aerospace

- Engine core parts: turbine discs, landing gear parts, need to withstand extreme temperatures and pressures

- Structural parts: wing frames, fuselage connectors, high strength-to-weight ratio achieved through titanium alloy forging.

- Main components/applications: Turbine shafts, engine blades, fuselage structures, landing gear components, flight control components.

- Forging features: High-temperature alloy forgings have excellent high-temperature resistance and creep resistance, meeting the harsh working conditions of aircraft engines.

Automotive industry

- Powertrain: crankshaft, connecting rod, use the high fatigue strength of forging to improve engine life.

- Transmission system: gears, drive shafts, optimize grain structure through hot forging to reduce wear.

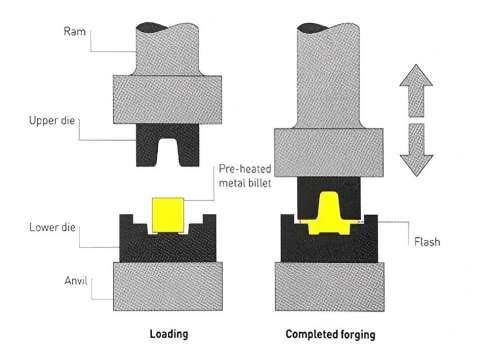

- Forging features: Forging improves metal grain structure through compression deformation, providing extremely high strength and fatigue life, and is suitable for key components that bear large loads.

Die casting and forging applications:Energy and heavy industry

- Power generation equipment: turbine rotors, nuclear reactor pressure vessels, require ultra-high strength materials.

- Oil and gas: valves, flanges, resist corrosion and high pressure through stainless steel forging.

- Forging feature: Large size and high strength requirements make forging the preferred process.

Construction and infrastructure

Fasteners

Bolts, nuts, cold forging process to ensure dimensional consistency of mass production.

Heavy machinery

Excavator bucket teeth, hooks, wear resistance enhanced through hot forging. Military and defense.

Weapon parts

Barrels, armor plates, forged with high-strength steel to improve impact resistance.

Manufacturing Process Selection

HAICHEN provides the technology and expertise to implement die casting solutions effectively.

- Help The Manufacturer Choose the Right Process

- HAICHEN die casting machine Advantage

Case: Help The Manufacturer Choose the Right Process

One of Haichen metal manufacturer was developing a new aluminum bicycle crankarm. They debated between forging for strength and die casting for complex shaping and cost. HAICHEN engineers analyzed the design. We showed that with a high-integrity die casting process using our precision machine, they could achieve the required strength while integrating mounting features directly into the part. This eliminated machining steps. By choosing die casting with HAICHEN, they reduced total part cost by 25% and accelerated time to market.

HAICHEN die casting machine Advantage

Haichen as one of die casting machine manufactuers over 10years who help clients analyze their product needs to select the most efficient process. For die casting applications, our machines offer the stability, precision, and control needed to push the performance boundaries of cast parts, often making them a viable and superior alternative to forging for the right application.

Selection principles of Die cating and Forging

Die casting

Die casting dominates industries requiring lightweight, complex geometry, high surface quality, and high volume production (automotive, aviation, electronics, hardware).

Forging

Forging is essential for critical structural parts that withstand high loads and require excellent mechanical properties (engine crankshafts, aircraft turbines, and heavy machinery).

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.