What is the ejector space of the die casting machine

The ejector space of the die casting machine is the distance that the die-casting ejector moves during the ejection process. That is, the distance between the end face of the die-casting ejector and the working surface of the fixed template. The ejector space of the die casting machine is an important parameter to ensure the […]

What is die casting machine ejector stroke ?

The die casting machine ejector stroke is the maximum movement distance of the ejector of the die casting machine. It is an important parameter to measure the demoulding ability of the die-casting machine. The die casting machine ejector stroke is represented by S and the unit is mm. The importance of ejection stroke The Die […]

What is die casting machine ejector force?

Die casting machine ejector force is the force used by the die-casting machine to eject the formed casting from the die after the die-casting process is completed. Sometimes we also call die casting machine ejector force, ejector pressure. This is the key force to ensure that the casting can be smoothly separated from the die […]

What is casting pressure of die casting

Casting pressure of die casting is the pressure at which a liquid or semi-solid metal or alloy is filled into a mold cavity at high pressure and speed during the casting process. This casting pressure of die casting ensures that the metal completely fills every nook and cranny of the mold, resulting in a high-quality, […]

What does die casting projection area mean?

“Cast projection area” in die casting is the area of the mold cavity projected onto the parting surface. This area is calculated by projecting the three-dimensional casting onto a flat surface, specifically, onto the parting surface of the mold. The projection area plays a crucial role in the design phase, as it determines the opening force generated […]

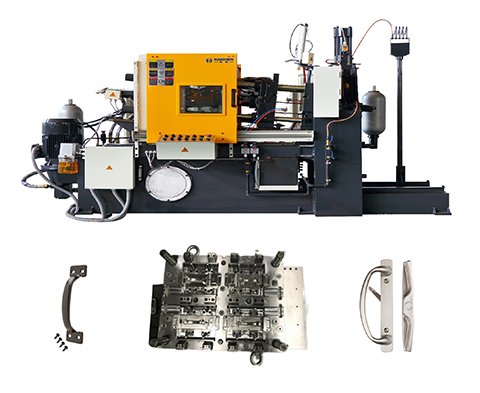

Types of Die Casting Machines

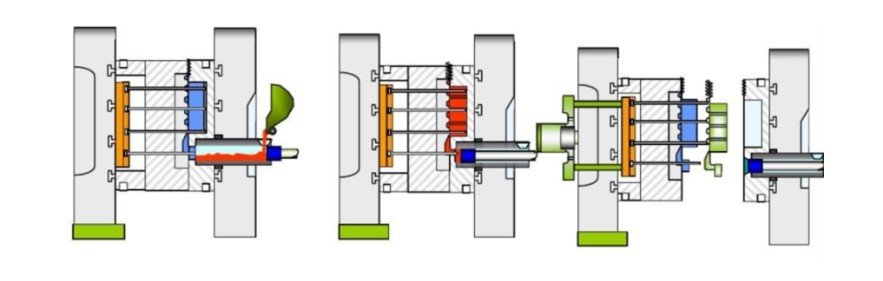

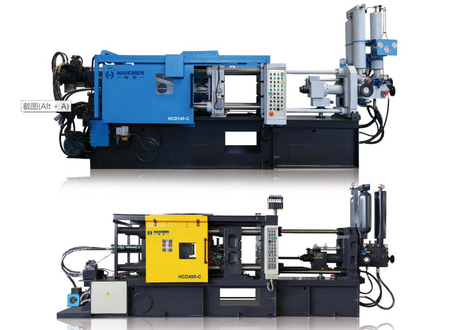

There are two primary main types of die casting machines: Hot chamber die casting machine: The casting chamber and casting head are immersed in molten metal liquid, which is suitable for die casting of low melting point alloys such as zinc and lead. Cold chamber die casting machine: The casting chamber and casting head are not immersed […]

The casting stroke of a die casting machine

The casting stroke of a die casting machine is the distance traveled by the injection punch from the starting position to the end position. So the casting stock = injection stock. In the die casting process, the movement of the injection punch is divided into several stages, including slow injection, fast injection, and pressurization, among […]

What is the Tank capacity for die casting machine?

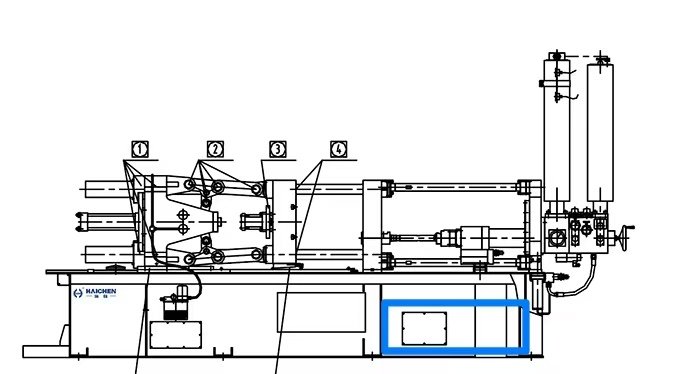

Tank capacity for die casting machines is the volume of hydraulic oil that can be held in the die casting machine tank, usually in liters (L). It is directly related to machine lubrication, cooling, stability, energy efficiency, productivity, environmental impact, cost-effectiveness, and process and quality control. Impact of Tank Capacity on Die Casting Machine Performance […]

What is the system working pressure of the die casting machine

The system working pressure of a die casting machine is the normal pressure in a hydraulic system of die casting machine. Usually the system working pressure determined by the output pressure of the hydraulic pump. During the die-casting process, system working pressure plays a crucial role in ensuring that the molten metal can be effectively […]

Oil consumption of machine burner

Oil consumption of machine burner: how much oil will be used during the machine burner working. The Oil consumption of machine burner is the main part to calculating the cost of the production. The fuel consumption of the combustion furnace of a hot chamber die casting machine can be affected by a variety of factors, […]