Benefits of zinc in hot chamber die casting are primarily based on its low melting point, high fluidity, high strength, resistance to wear, dimensional accuracy, electrical and thermal conductivity, and etc.

At the processing level, zinc alloys possess the lowest melting point (except for lead), the lowest specific heat capacity, and the highest fluidity. These physical properties enable the casting of thinner walls and more complex shapes, achieving faster cycle times and significantly longer die life compared to other die-casting alloys. The inherent corrosion resistance of zinc, the superior performance of zinc alloys, and the efficient and flexible nature of the die-casting process combine to create a significant competitive advantage.

The application of zinc alloys in die casting not only facilitates product development and simplifies production processes, ultimately resulting in durable finished products. Zinc’s strength, ductility, and stability enable professionals to manufacture higher-quality, more durable products.

Benefits of zinc in hot chamber die casting

Zinc offers several benefits in hot chamber die casting, making it a popular choice for this manufacturing process. Here are the key advantages.

- Low melting point and high fluidity

- High strength and wear resistance

- Excellent dimensional accuracy and consistency

- Good electrical and thermal conductivity

- Cost-effective and environmentally friendly

- Long mold life and low maintenance requirements

- Fast production cycle times

- Versatile Surface Finishing Capabilities

- Suitable for complex designs

Low melting point and high fluidity

- Zinc alloys have a low melting point (approx. 419.5°C), which makes them ideally suited for hot chamber die casting processes.

- The low melting point not only reduces the amount of energy required for heating, but also shortens cycle times, thus increasing productivity.

- In addition, zinc alloys are extremely fluid in the molten state, which allows them to fill complex mold designs and form thin-walled structures and precision-sized parts.

High strength and wear resistance

- Zinc alloys have excellent mechanical properties, including high strength, high hardness and good wear resistance.

- These properties allow zinc die castings to withstand heavy loads, vibration and harsh environmental conditions while maintaining structural integrity and performance.

Excellent dimensional accuracy and consistency

- The high fluidity of zinc alloys allows them to produce parts with high dimensional accuracy and consistency.

- This is important for applications that require precise fit and positioning.

Good electrical and thermal conductivity

- Zinc alloys have good electrical and thermal conductivity, which makes them ideal for use in electronic components.

- This property also makes zinc alloys excellent in the manufacture of heat sinks, electrodes and other parts that require thermal conductivity.

Cost-effective and environmentally friendly

- Zinc alloys are relatively inexpensive to produce and due to their recyclability, zinc die castings have a low environmental impact.

- In addition, the use of zinc alloys reduces the need for other, more expensive materials, further lowering production costs.

Long mold life and low maintenance requirements

- Zinc alloys are commonly used in hot chamber die casting machines because these alloys do not corrode or erode machine parts, thus extending the life of the mold and equipment.

Fast production cycle times

- The hot chamber die casting process has very short cycle times, often reaching hundreds of injections per hour, which makes zinc alloys ideal for high-volume production.

Versatile Surface Finishing Capabilities

- Zinc die castings can be finished with a variety of surface treatments (e.g. plating, painting, etc.) to achieve the desired appearance and durability.

Suitable for complex designs

- The high fluidity of zinc alloys enables the manufacture of complex part designs, including thin-walled structures and precision-sized zeros.

Technical basis of hot chamber die casting

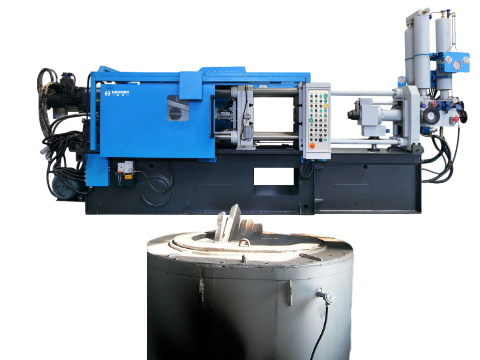

In a hot chamber injection molding machine, the injection mechanism is immersed in a molten metal pool within a metal furnace.

This furnace connecting to the machine via a metal conveying system a gooseneck.

As the plunger in the injection cylinder rises, the opening port on the cylinder opens, allowing molten metal to flow in. As the plunger descends, the port closes, forcing the molten metal through the gooseneck and nozzle into the mold cavity. After the metal solidifies within the cavity, the plunger retracts, the mold opens, and the casting is ejected.

Hot chamber injection molding machines are primarily used for zinc, magnesium, lead, and other low-melting-point alloys,

As these materials are less likely to corrode the molten metal pool, cylinder, and plunger.

We can configure a complete production line for you, featuring high-quality, durable components.

Haichen zinc alloy die casting machine supplier

Haichen is a well-known supplier of zinc alloy die casting machines, offering a range of equipment designed for high efficiency, precision, and reliability in the die casting process.

Besides zinc alloy die casting machine, we also supply cold chamber die casting machines, aulixiary equipmets and spear parts.

And Haichen machines are equipped with advanced features such as real-time monitoring systems, energy-saving designs, and high-precision control systems to ensure optimal performance and efficiency. if there is any demand, welcome to consult us.