Selection tips for nozzle in die casting

Die casting nozzle selection tips includes material selection, nozzle size and shape, Heat and surface treatment and so on. When selecting a die casting nozzle, you need to consider multiple factors

Die casting nozzle selection tips includes material selection, nozzle size and shape, Heat and surface treatment and so on. When selecting a die casting nozzle, you need to consider multiple factors

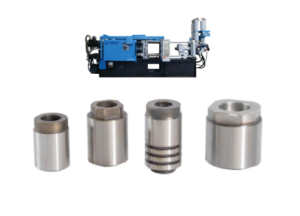

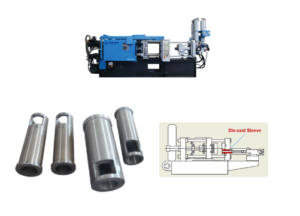

Manufacturer of Plunger Tips for Die Casting Machines: Plunger tips also known as the plunger head of the die casting machine is the core component of the die casting process.

Plunger Tips are the end part and most critical element of the shot end assembly. Its role is to contact the molten metal and force it through the sleeve and

When selecting die casting plunger tips, key factors include material compatibility with the molten metal, tip geometry for optimal flow and pressure control, durability to withstand high – pressure injection,

Plunger tips for die casting are component utilised within the injection sleeve of a die-casting machine. It is designed to regulate the flow of molten metal into the injection sleeve,

Plunger Tip for Die Casting includes its function, material selection, customization and maintenance, design and optimization and so on. The plunger tip is a critical component of the die-casting machine’s shot-jetting system.

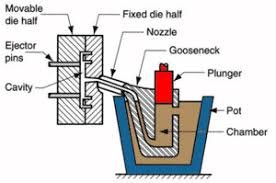

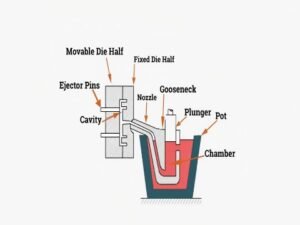

Haichen Machinery is a professional die casting machine gooseneck pot producer. In hot chamber die casting machines, gooseneck pots (or goosenecks) are the key components connecting the furnace and the

Choose gooseneck in die casting includes material characteristics, heat resistance and mechanical strength, structural design and so on. In a hot chamber (gooseneck) die-casting machine, the gooseneck is the critical channel that

Gooseneck die casting, also known as hot-chamber die casting, is an efficient metal casting process ideal for low-melting-point alloys (e.g., zinc, magnesium, lead). The gooseneck tube is a critical component

The gooseneck in die casting is a crucial component that transfers molten metal from the injection system to the mold cavity, ensuring smooth and efficient metal flow during the casting