Why does metal splash sometimes occur during die casting?

Metal splash occur during die casting includes: insufficient mold clamping force, injection pressure is too high or injection speed is too fast and so on. Metal splash, or the violent

Metal splash occur during die casting includes: insufficient mold clamping force, injection pressure is too high or injection speed is too fast and so on. Metal splash, or the violent

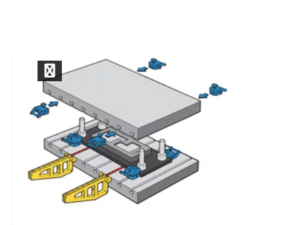

Quick Die Change Systems enables the automation of the mold-changing process, significantly enhancing the production speed, efficiency and productivity of the workshop. A quick die change system is an automated

Quick Die Change System (Quick Die Change System) in the die casting process application is mainly focused on the rapid replacement and installation of the mold to improve production efficiency

Composition of the quick mold change system: clamp, mould transfer arm, mould lifter, pneumatic and hydraulic power unit, control system and so on. The Quick Mold Change System is a mold

The key methods for quick die change (QDC) systems in die casting involve a combination of methodologies, mechanical innovations, automation, and process optimization. Technical details of die casting rapid mold

Discover the Advantages of Quick Die Change Systems for Die Casting: reduced downtime, increased productivity, and enhanced flexibility. In the highly competitive world of die casting, efficiency and productivity are

Tie bar load calculation in the die casting process, the tie rod is a key connecting component between the die casting machine and the mold. And it is directly related

Die cast machine tie bar is critical components that maintain the structural integrity of the machine during the high-pressure die casting process. Over time, tie bars can experience wear, stretching,

Die casting machine tie bar (also called tie rods or columns) are critical components in die casting machines, providing structural integrity and ensuring precise alignment during the casting process. In automatic tie bar

Die casting machine tie bars break because excessive mechnical stress, metarial and design issues, production speed and mold design and so on. The core of tie rod breakage is unbalanced stress