How to choose Extractor in die casting

Choose extractor in die casting includes application and model matching scope, technical performance and functionality, etc. The extractor is the picking machine of a die casting machine. It is a

Choose extractor in die casting includes application and model matching scope, technical performance and functionality, etc. The extractor is the picking machine of a die casting machine. It is a

Technical parameters of ladle in die casting: Ladle in die casting process undertakes the functions of transporting and pouring molten metal. By holding molten steel, die-cast ladles in low-pressure casting thereby apply

Select ladle in die casting includes material selection, size and shape, operation mode, process requirements, etc. When choosing a ladle for die casting, you need to consider factors such as

Ladle Components in die casting include ladle cup, main frame, pouring spout, handle & lever mechanism, temperature control features, and etc. In the die casting process, the ladle is an

When we facing the material selection for ladle in die casting,we alwasy significantly impacts their performance, durability, and casting quality. In cold chamber die casting, a ladle is used to

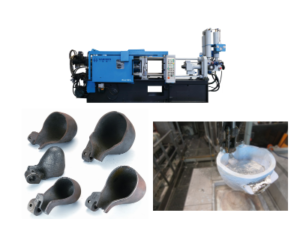

Die casting solution for Ladle ensures precise molten metal transfer with optimized temperature control and minimal oxidation. Die casting is a precision manufacturing process used to produce high-quality metal parts

Die casting mold cost optimization strategy includes material selection, optimize mold design, structural topology optimization, etc. The cost optimization strategy of die casting molds involves material selection, design optimization, maintenance

Common Die casting mold Problems & Solutions: Die casting mold problems are closely related to temperature control, mold design and process parameters. Defects can be significantly reduced and yield improved

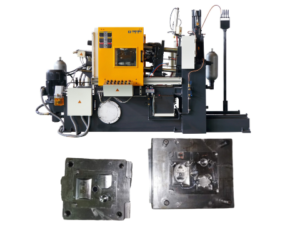

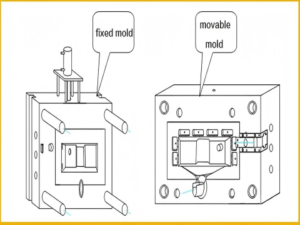

Components of die casting mold mainly includes cavity and core, sprue and gating aystem, mold base and support structure. Die casting molds, also known as die casting dies, are essential

Aluminum alloy die casting mold is a key tool used to fill molten metal at high pressure and high speed to manufacture complex parts. Accurate aluminum alloy die-casting mold design