Cold chamber die casting machine development trend includes automobile manufacturing industry, electronics industry and other industries.

The development trend of cold chamber die casting machines is centered on intelligence, large-scale and environmental protection. Technological progress has promoted the improvement of production efficiency and product quality, while the diversification of market demand requires equipment to have stronger adaptability and flexibility.

In the future, cold chamber die casting machines will continue to play a key role in new energy vehicles, high-end electronics and other fields, and respond to the sustainable development needs of the global manufacturing industry through technological innovation.

Cold chamber die casting machines have shown significant advantages in many specific application scenarios. The following is main application areas and their advantages:

- Automobile Manufacturing Industry

- Electronics Industry

- Aerospace industry

- Medical devices

- Home appliance industry

- Other industries

Automobile Manufacturing Industry

Automobile Manufacturing Industry

- Application of magnesium alloy

- High production efficiency

- lightweighting automobiles drive market growth

- The driving force of new energy vehicles

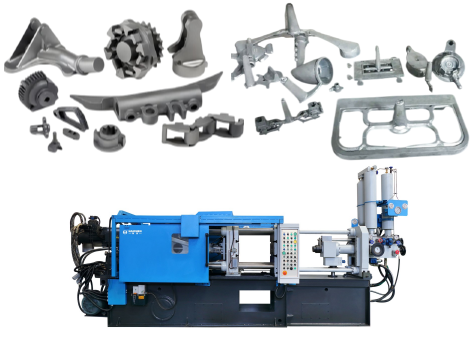

Cold chamber die casting machines play an important role in the automobile manufacturing industry.They are particularly suitable for producing lightweight, high-strength parts. For example:

Key parts such as engine housings, gearbox housings, luggage racks, and wheels: These parts require high precision. Smooth surfaces, and excellent mechanical properties, and cold chamber die casting machines can meet these requirements.

Application of magnesium alloy

Due to its low density and high strength. Magnesium alloy widely use in lightweight automobile production, such as dashboard beams, seat frames, etc.

High production efficiency

Cold chamber die casting machines can achieve rapid prototyping and efficient production to meet mass production needs.

lightweighting automobiles drive market growth

- Cold chamber die-casting machines have become the core technology for lightweighting automobiles because they can produce high-precision, complex and lightweight aluminum alloy parts.

- For example, the requirements of electric vehicles (EVs) for battery life and energy efficiency have promoted the widespread use of aluminum parts like aluminium alloy road stud. It is expected that the aluminum consumption per vehicle will reach 250kg in 2025 and further increase to 350kg in 2030.

- The high pressure (30-150 MPa) and adaptability to high-melting-point materials (such as aluminum and magnesium alloys) of cold chamber die-casting machines make them the preferred process for producing key components such as engine blocks and gearbox housings.

The driving force of new energy vehicles

- The dual demands of new energy vehicles (NEVs) for lightweight and cost control have accelerated the market penetration of cold chamber die-casting machines.

- For example, the integrated die-casting technology (Ultra-Essentia) adopted by Tesla reduces the number of parts and welding processes, reducing production costs, prompting traditional die-casting companies to accelerate technology upgrades.

- The growth of the Chinese market is particularly significant. In 2021-2022, China’s cold chamber die-casting machine market will leap from 6000T to 16000T, and the proportion of new energy vehicle orders will continue to rise.

Electronics Industry

- High precision and surface quality

- High degree of automation

- Miniaturization and customization needs

Cold chamber die casting machines mainly use in the electronics industry. To produce parts such as housings, brackets and connectors for mobile phones, laptops, tablets and other devices. Its advantages include:

High precision and surface quality

- Cold chamber die casting machines can ensure the dimensional accuracy and surface finish of parts. mprove the overall performance and user experience of electronic products.

- Cold chamber die-casting machines have become the preferred process in the electronics industry (especially 3C electronics) because they can produce high-precision, complex structure parts (such as battery housings, radiators, micro connectors, etc.).

- For example, it is pointed out that cold chamber die-casting technology significantly improves the mechanical properties and surface quality of products. By precisely controlling the alloy composition and cooling process, meeting the requirements of electronic equipment for lightweight and high reliability.

High degree of automation

- By integrating advanced control systems and automation technologies, cold chamber die casting machines can improve production efficiency and reduce labor costs.

- In the future, cold chamber die-casting machines will integrate machine learning algorithms.

- It will reduce energy consumption through predictive maintenance and parameter optimization, adapting to the needs of electronic manufacturing for high efficiency and low cost.

Miniaturization and customization needs

As electronic devices develop towards miniaturization, miniaturized models of cold chamber die casting machines (such as Haichen’s HCD-C series) are gradually emerging to meet the needs of mobile phones, wearable devices, etc. for precision micro parts.

Aerospace industry

- Material innovation

- Process optimization

- Equipment performance improvement

- Lightweight applications

- Sustainability

- High strength and corrosion resistance

- Environmental protection and energy saving

Cold chamber die casting machines are used in the aerospace industry to produce high-performance alloy structural parts and components, such as aircraft engine components and precision tools. Its advantages include:

Material innovation

The aerospace field has extremely high requirements for components (high temperature resistance, corrosion resistance, lightweight, high strength). Traditional aluminum alloys can no longer meet the needs. New materials such as titanium alloys and high-temperature alloys have become the focus of research and development. Cold chamber die-casting machines have become key equipment because they can process high-melting-point metals (such as aluminum, magnesium, and copper alloys).

Process optimization

Advanced technologies such as vacuum die-casting and squeeze casting are widely used to significantly reduce pores and shrinkage defects and improve the internal quality and dimensional accuracy of components. For example, vacuum die-casting technology meets the high standards of aerospace components by improving filling and solidification methods.

Equipment performance improvement

Modern cold chamber die-casting machines ensure high-precision repetitive production by shortening the pressurization time, increasing the injection speed and stability, and are suitable for complex components such as aircraft engine parts and turbine blades.

Lightweight applications

Cold chamber die casting can manufacture parts with high strength-to-weight ratio (such as aircraft structural parts and fuel system parts), helping to reduce aircraft weight and improve fuel efficiency, which is in line with the lightweight trend in the aerospace industry.

Sustainability

The cold chamber die casting process has high material utilization and low energy consumption, which meets the environmental protection requirements of the aerospace industry. For example, environmentally friendly coatings and waste recycling technologies are used to reduce pollution

High strength and corrosion resistance

Cold chamber die casting machines are able to produce high-strength, corrosion-resistant complex parts that meet the stringent requirements of the aerospace industry.

Environmental protection and energy saving

Cold chamber die casting machines have a stable operation process, less waste, and meet modern environmental protection requirements.

Haichen Practice in Cold Chamber Die Casting Machine Development Trendtrends

HAICHEN actively uses these trends in our machines to create value for customers.

- Servo Energy-Saving System in Automotive Production case

- Haichen Smart die casting System for High-Quality Parts

Servo Energy-Saving System in Automotive Production case

A car parts maker wanted to cut costs and improve stability. They chose a HAICHEN 800-ton cold chamber machine with a full servo system. This machine gave them precise control for complex parts. More importantly, it reduced their energy use by over 35%. The stable performance also lowered their defect rate. This investment paid back quickly through savings.

Haichen Smart die casting System for High-Quality Parts

One electronic housings producer had issues with part shrinkage. HAICHEN’s solution was a machine with our smart multi-stage injection system. This system allows for ten separate control stages for speed and pressure. By fine-tuning the profile, we solved the shrinkage problem without slowing production. This shows how HAICHEN turns trends into practical solutions.

The Cold Chamber Die Casting Machine Development Trend is clear: machines are becoming more efficient, intelligent, and precise. These changes help manufacturers save energy, reduce waste, and produce higher quality parts. Staying updated with these trends is key to staying competitive. As HAICHEN’s cases show, choosing a partner that invests in these advanced technologies brings direct benefits in cost, quality, and productivity for your business.

Medical devices

- High precision and improved stability

- High precision and reliability

- Diverse material applicability

Cold chamber die casting machines are used in the field of medical devices to produce precision medical devices and surgical tools.

High precision and improved stability

Medical equipment requires extremely high component precision. Cold chamber die casting machines achieve more precise injection control and repeatability by optimizing hydraulic systems, servo control and human-machine interface (HMI).

High precision and reliability

Cold chamber die casting machines can produce parts with high dimensional accuracy and good surface quality, ensuring the safety and effectiveness of medical devices.

Diverse material applicability

Cold chamber die casting machines support the processing of a variety of metal materials, such as aluminum alloys, magnesium alloys, etc.

Home appliance industry

- Significant economic benefits

- High production efficiency

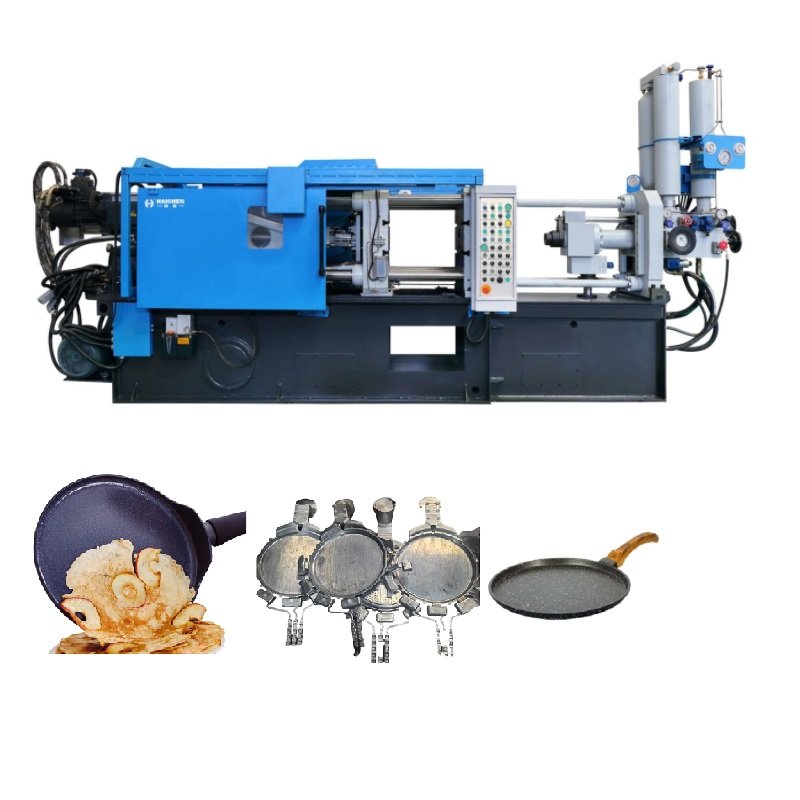

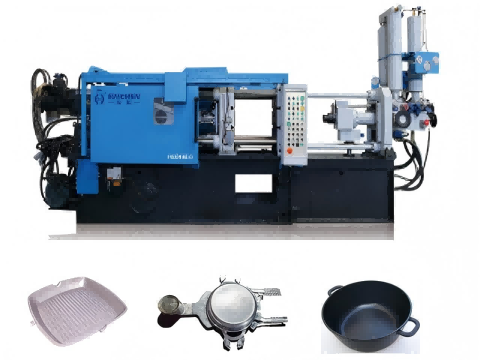

Cold chamber die casting machines are used in the home appliance industry to produce various hardware accessories, such as parts for refrigerators, air conditioners, washing machines and other equipment. Its advantages include:

Significant economic benefits

Due to the precise size and smooth surface of the parts, the need for secondary processing is reduced, reducing costs.

High production efficiency

Cold chamber die casting machines can achieve large-scale production and improve production efficiency.

Other industries

- High precision and durability

- Energy saving and environmental protection

Cold chamber die casting machines are also widely used in building hardware, sports equipment, power tools and other fields.

High precision and durability

Cold chamber die casting machines can produce parts with high dimensional accuracy. And with good surface quality, extending the service life of products.

Energy saving and environmental protection

Compared with traditional hot chamber die casting machines, cold chamber die casting machines are more energy-saving, reducing energy consumption and scrap rate.

Thus cold chamber die casting machines have shown significant advantages in many industries. Such as automobiles, electronics, aerospace, medical devices, and home appliances. Due to their high efficiency, high precision, energy saving, and environmental protection. They can meet the production needs of complex parts, and further improve production efficiency and product quality through automation and intelligent technology.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

When you have any demand of selecting cold chamber die casting machine, feel free to contact us.