Die casting machine platens are critical components that hold the mold halves and withstand significant clamping forces. Common problems with platens can affect machine performance, part quality, and tooling life.

Platen issues in die casting machines often stem from misalignment, wear, overloading, or poor maintenance.

Regular inspections, proper alignment, and timely repairs can extend platen life and ensure consistent casting quality.

Common problems and solutions for die casting machine platens

Below are typical issues and their solutions for die casting machine platens:

- Cold Shut

- Soldering and Sticking

- Die Wear

- Die Deformation

- Flash

- Porosity

- Die Adhesion

- Erosion

- Misalignment

- Surface Roughness

Cold Shut

It refers to the phenomenon where the molten metal fails to fully fuse, resulting in unmelted traces on the surface of the casting.

Causes: Insufficient mold preheating, low pouring temperature, or poor metal flowability.

Solutions: Increase the mold temperature, optimize the gate design, enhance the metal flowability, and adjust the injection speed to ensure thorough mixing of the molten metal.

Soldering and Sticking

Soldering and sticking occur when the molten metal adheres to the mold surface, making it difficult to open the mold or causing defects on the casting surface.

Causes: Excessive mold temperature, improper use of lubricants, or residual materials on the mold surface.

Solutions: Control the mold temperature within an appropriate range, use suitable release agents, and keep the mold clean.

Die Wear

Long-term use can lead to mold surface wear, affecting the quality of the casting and the mold’s lifespan.

Causes: Repeated use of the mold, insufficient lubrication, or inadequate material hardness.

Solutions: Regularly inspect and maintain the mold, replace severely worn components, and increase the mold material hardness.

Die Deformation

Molds may deform under high temperature and pressure, affecting the precision of the casting.

Causes: Unreasonable mold design, insufficient material strength, or uneven heating.

Solutions: Optimize the mold design, select high-strength materials, and ensure even heating of the mold.

Flash

Flash occurs when the molten metal flows beyond the mold contour, resulting in excess metal on the casting surface.

Causes: Excessive injection pressure or large mold clearance.

Solutions: Adjust the injection pressure, optimize the mold clearance, and ensure tight mold closure.

Porosity

Porosity is caused by air or gas trapped in the molten metal, forming voids that reduce the mechanical properties of the casting.

Causes: Rapid cooling of the molten metal or insufficient mold preheating.

Solutions: Extend the molten metal’s dwell time in the mold, use vacuum degassing technology, and optimize the cooling system.

Die Adhesion

Die adhesion happens when the mold surfaces stick together due to high temperature or poor lubrication, causing production interruptions.

Causes: Improper selection of lubricants or excessive mold temperature.

Solutions: Choose suitable lubricants and control the mold temperature within a reasonable range.

Erosion

High-speed molten metal can erode and corrode the mold surface due to its impact.

Causes: High-speed metal flow or insufficient mold material strength.

Solutions: Optimize the mold design, apply wear-resistant coatings, and reduce the molten metal speed.

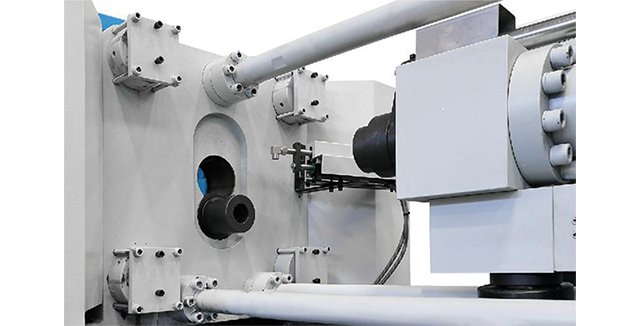

Misalignment

Misalignment of the mold can lead to dimensional deviations or surface defects in the casting.

Causes: Loose mold fastening or failure of the alignment device.

Solutions: Inspect and secure the mold fastening devices, and regularly maintain the alignment system.

Surface Roughness

The surface roughness of the mold affects the quality of the casting surface and increases the difficulty of subsequent machining.

Causes: Insufficient lubrication or inadequate mold material hardness.

Solutions: Improve lubrication conditions and increase the mold material hardness.

Comprehensive Recommendations

To effectively reduce common issues related to die casting machine platens and improve production efficiency and product quality, the following measures are recommended:

- Regularly inspect and maintain molds and die casting equipment to ensure they are in good condition.

- Optimize mold design, including the layout of gates and cooling systems.

- Use high-quality lubricants and release agents to ensure a smooth mold surface.

- Control production parameters such as injection pressure, temperature, and time to minimize defects.

- Provide enhanced training for operators to improve their understanding of equipment and processes.

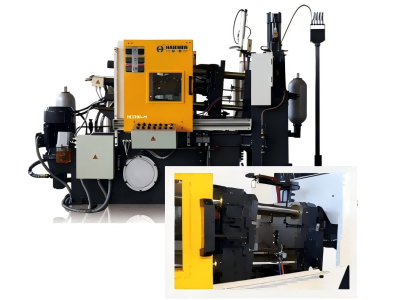

Die Casting machine supplier: Haichen Machinery

Haichen Machinery is a Chinese company specializing in the manufacturing and supply of aluminum cold chamber die casting machines, hot chamber die casting machines and related equipment.

- The advantage of Haichen die casting machine platens

- High Precision and Stability

- Adaptive Clamping Force Adjustment

- Shortened Dry Cycle Times

The advantage of Haichen die casting machine platens

High Precision and Stability

Haichen’s die casting machine platens are designed to ensure high precision and stability during the casting process. The platens are manufactured with high-quality materials and advanced manufacturing techniques to maintain tight tolerances and consistent part quality.

Adaptive Clamping Force Adjustment

Haichen’s Adaptive Clamping Force Adjustment Technology allows for real-time adjustments of clamping force to better adapt to different production needs. This feature improves production efficiency and product quality by ensuring more uniform clamping force distribution.

Shortened Dry Cycle Times

Through optimization of components and parameters, Haichen’s machines can significantly reduce dry cycle times. This improvement increases productivity by making the mold transfer operation faster.

If there is any demand for die casting machines or molds, welcome to consult us.