Die casting boosting handwheel repair includes disassembly, cleaning, measuring key components, finishing the surface and reassembly.

The booster handwheel is a manual control device in die casting machine operations, mainly used to accurately adjust machine parameters (such as injection pressure and clamping force) to improve casting quality, production efficiency and safety. Its function is closely related to the booster system (such as the booster cylinder).

In this blog, we will analyze the die casting machine boosting handweel repair from it’s basic function and adjustment. Secondly, the die casting machine boosting handweel repair common problems and relative solutions. Thirdly, we will introduce the optimize boosting system method and repair technology.

- Function and adjustment

- Common problems and repair methods

- Optimization and maintenance of booster system

- Material selection and surface treatment

- Application of modern repair technology

Function and adjustment

- Improve casting quality

- Processing of complex thin-walled parts

- Improved production efficiency

- Safety

- Mechanical Adjustment

The booster handwheel is used in die casting machines to adjust the stroke depth or pressure of the die. For example, it mentions that the operator needs to adjust the stroke depth by rotating the handwheel. Which shows that the handwheel is an important component to achieve die stroke control.

In addition, it also mentions that the handwheel designs to ensure safety, reliability and labor saving. Morover, its height and stroke can adjust by a timer to optimize the cutting position, thereby extending the service life of the equipment.

Manual operations can be used to achieve the following goals:

Improve casting quality

Increase injection pressure to make the molten metal fill the mold cavity more evenly, reducing defects such as pores and cold shuts.

Processing of complex thin-walled parts

For thin-walled or complex structure parts, the booster system provides precise pressure control to ensure complete filling.

Improved production efficiency

Optimizing mold filling speed shortens cycle time and increases output.

Safety

Ergonomic design reduces operator fatigue and the risk of accidents.

Mechanical Adjustment

Clamping Force Adjustment:

- Change the clamping force by rotating the tie bar nut. The following steps are included:

- Slightly rotate the nut to the desired position to generate the appropriate clamping force.

- Switch the mold adjustment switch to “off.”

- Open and close the mold repeatedly to check the preload and ensure the piston rod reaches its end position and triggers the travel switch.

- Note: If adjustment becomes uncontrolled, stop the machine immediately, troubleshoot the problem, and restart the machine.

Limit Adjustment

- Some handwheels are equipped with limit devices to limit valve opening (e.g., for minimum flow control):

- Steps: Adjust the valve to the desired position → Remove the fastening screws → Install the valve stem limit cap → Re-tighten the screws

Hydraulic Parameter Adjustment

Boost Speed Adjustment

Adjust the slow, fast, and boost speed settings via the control valves on the oil manifold, directly affecting the metal filling process.

Injection Pressure Optimization

- If the casting exhibits underfill or flash, adjustments may be required:

- Insufficient pressure: Replace with a larger tonnage die-casting machine or increase the shot pressure.

- Flash Issues: Check for uniform clamping force and fine-tune the tie rod nut.

Common problems and repair methods

- Hydraulic system instability

- Mold stuck (high operating resistance)problem and method

- Heat cracking (component damage)

- Porosity/Flash (affecting precision)

According to the company, the repair of die-casting mold tools usually includes disassembly, cleaning, measuring key components, finishing the surface and reassembly. If the handwheel is worn or damaged, it can be repaired by following these steps.

In addition, when repairing the handwheel, check for obstacles that hinder function. Such as entangled wire ends or impurities and ensure that the handwheel area is clean and unobstructed.

Hydraulic system instability

Problem

Fluctuating injection speed, resulting in inaccurate boost pressure, affecting handwheel control of mold filling.

Causes

Hydraulic pump flow valve failure, seal wear, or leakage.

Method

- Check and calibrate the hydraulic pump flow valve to ensure stable pressure.

- Replace worn seals and eliminate leaks.

Prevention

Regularly monitor hydraulic fluid cleanliness to prevent clogging with impurities.

Mold stuck (high operating resistance)problem and method

Problem

Abnormal resistance during handwheel adjustment, possibly accompanied by flash.

Causes

- Impurities or wear on the mold parting surface, leading to a poor seal.

- Insufficient clamping force or excessive injection pressure, allowing molten metal to penetrate the mold gap.

Method

- Clean the mold parting surface, remove impurities, and lubricate sliding parts (e.g., using a graphite-based lubricant).

- Adjust the clamping force: Reduce the injection pressure or increase the clamping force.

Prevention

Regularly inspect the mold for wear and promptly repair or replace damaged parts.

Heat cracking (component damage)

Symptoms

Cracks on the boost cylinder or mold surface where the handwheel is connected.

Causes

- Uneven mold temperature or excessively rapid cooling rate, resulting in shrinkage stress.

- Incorrect alloy composition (e.g., iron content below 0.6%), reducing material toughness.

Method

- Pretreatment: Clean the cracked area and grind to remove the oxide layer.

- Welding:

- Use a welding rod with the same composition as the mold steel (e.g., H13 for H13 steel).

- Preheat the mold to 180–200°C (to avoid thermal stress).

- Weld under a shielding gas (e.g., argon) to ensure uniform penetration.

- Post-treatment: Cool slowly to avoid secondary cracks.

Porosity/Flash (affecting precision)

problem

Increased porosity or flash on the casting surface, and ineffective handwheel pressure adjustment.

Causes

- Excessive injection speed causes turbulent metal flow and gas entrapment.

- Insufficient clamping force or mold wear, causing metal overflow.

Solution

- Optimize injection parameters: Reduce injection speed to avoid turbulence; increase boost pressure to ensure adequate filling.

- Improve venting: Clean venting slots or add overflow slots to facilitate gas discharge.

- Adjust mold clamping: Calibrate clamping force to ensure a tight mold closure.

Prevention

- Control alloy melting temperature (to reduce gas dissolution).

- Apply release agent evenly (to avoid excessive application, which can lead to gas volatilization).

Optimization and maintenance of booster system

- Optimization Strategies

- Precise Control of Production Parameters

- Regular Maintenance Items

The booster cylinder is a system. It uses to push the mold forward and return to the initial position, which can reduce the impact on the material. Such a system usually requires regular maintenance to maintain its performance.

It points out that the adjustment of boost pressure needs to follow certain principles. Such as avoiding blindly increasing pressure, otherwise it may lead to a shortened mold life.

Optimization Strategies

- Integrate real-time sensors and data analysis tools to dynamically adjust pressure parameters.

- Use a vacuum system to improve airtightness and reduce internal porosity (this must be planned during the mold design phase).

- Avoid excessively high injection rates (“rushing” operations) to prevent mold damage.

Precise Control of Production Parameters

- Booster Stage: Boosts system pressure before filling the cavity to ensure dimensional accuracy.

- Key parameters: Boost Pressure Ratio, clamping force, and injection speed. Regular equipment calibration is required to ensure parameter accuracy.

Regular Maintenance Items

- Seal Maintenance:

Inspect and replace sealing components such as O-rings and sliding rings to prevent hydraulic leaks. - Ensure seals are properly seated during installation (for example, O-rings must be seated in the seal groove when tightening).

- Lubrication of Moving Parts:

Regularly lubricate pistons, bearings, and other components to reduce wear (for example, grease the centering piston and install the spring). - Use the designated lubricant to avoid chemical reactions with the material.

- Hydraulic System Inspection:

Monitor the oil level and contamination status, and replace the hydraulic oil promptly. - Check for leaks in the pipelines and replace damaged joints.

Material selection and surface treatment

- Material Selection

- General Treatment Technology

If the handwheel need to replace or repaire, you can choose a material suitable for the die casting machine environment. For example, 316 stainless steel often uses to manufacture valve handwheels. Because of its excellent corrosion resistance and crack resistance.

Material Selection

Die-cast power-assisted handwheels must balance lightweight, strength, corrosion resistance, and processability. Commonly used materials include aluminum alloy, magnesium alloy, and zinc alloy.

Surface treatment can improve the wear, corrosion, and fatigue resistance of repaired handwheels. The selection depends on the material properties and failure mode:

General Treatment Technology

Nitriding (gas/ion/salt bath nitriding):

- This creates a hardened layer, significantly improving erosion and soldering resistance. It is suitable for critical components such as nozzles and ejectors.

- The treatment must be customized based on the material composition (e.g., nitriding works best on H13 mold steel).

Application of modern repair technology

- Hybrid Manufacturing Technology

- Atomic Diffusion Repair Technology (for aluminum castings)

- Casting Defect Repair Machine Technology

3D printing and hybrid manufacturing technologies are using for mold repair. These technologies can quickly repair damaged handwheels and restore their original shape and function.

Hybrid Manufacturing Technology

Technical Principle: This technology combines additive manufacturing (such as direct laser deposition (DLD)) with subtractive manufacturing (such as 5-axis milling) to achieve precise repairs.

Atomic Diffusion Repair Technology (for aluminum castings)

Technical Principle: Atomic diffusion between the base metal and the filler material creates a metallurgical bond, repairing surface defects (such as pores and pinholes).

Casting Defect Repair Machine Technology

Technical Principle: Low-voltage, high-current resistance heating creates an instantaneous high-temperature fusion point at the defect, enabling rapid repair.

Solve a persistent pressure case

One of our Haichen customers reported unstable injection pressure. Their machine often lost boosting pressure, causing defective parts. A local technician replaced seals, but the problem returned quickly. HAICHEN’s service team diagnosed the issue as a worn handwheel shaft and damaged internal threads. We provided a complete repair kit with upgraded seals. Our engineer guided the local team through the precise repair process. After the fix, pressure stability was restored, and defect rates dropped significantly.

This case shows HAICHEN’s approach. We offer more than just machines. We provide long-term support with genuine parts and expert knowledge. Our goal is to minimize your downtime. Choosing HAICHEN means choosing a partner committed to your productivity.

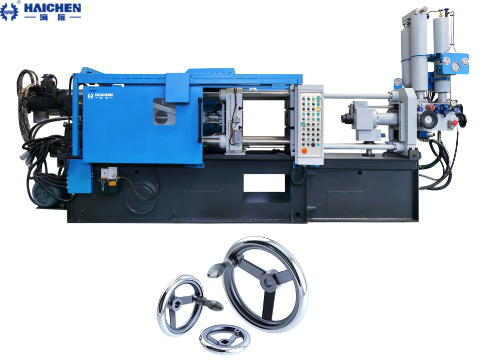

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.