Die casting cost have a variety of causes, including raw material selection, manufacturing process, equipment efficiency and recycling.

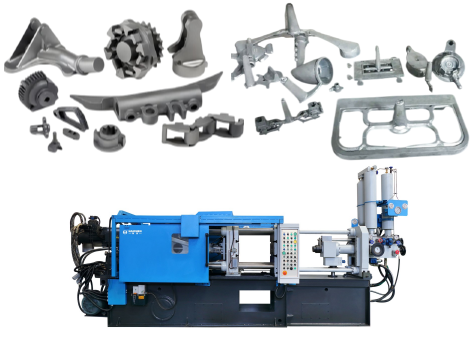

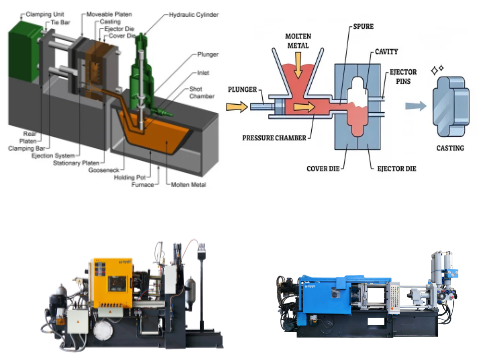

Die casting is a manufacturing process whereby molten metal is injected into a mould under high pressure. This technique produces complex components with precise dimensions and an exceptionally smooth surface finish.

This is particularly pertinent for bespoke die casting, a highly efficient and versatile manufacturing method. In this blog, we shall delve into the factors influencing die casting costs, explore cost optimisation strategies, and present practical case studies illustrating the importance of collaboration between procurement and design teams. Let us embark on this journey of die casting cost analysis together!

By optimising the process and material selection, the overall cost of die casting materials can be effectively reduced.

The influence of die casting material cost factors

Die casting material cost is affected by a variety of factors, including the price of raw materials, manufacturing process, equipment use efficiency and waste disposal.

For example, in the metal casting industry, large high-pressure die casting (HPDC) technology is widely used in automotive and other fields.

This technology by reducing the gate material and optimise the mould design to improve the production efficiency, so as to reduce the material cost per unit product.

The influence of material selection on the cost

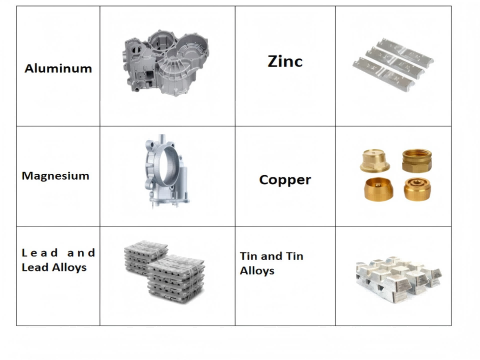

In the die-casting process, the choice of different materials will directly affect the cost.

The proportion of various types of metal alloy will cause the different cost of raw materials.

Manufacturing process contribution to cost

The complexity of the manufacturing process can also affect material costs. For example, the use of advanced DLC/TiAlN-coated die casting moulds reduces friction and wear, which extends mould life and reduces long-term production costs.

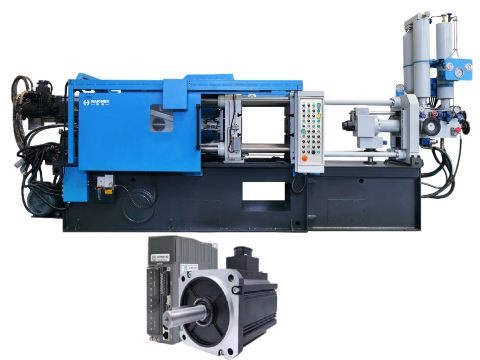

In addition, the use of automated equipment (e.g. robots) can further increase productivity and reduce labour costs.

Cost-effectiveness of recycled materials

The use of recycled materials can significantly reduce the overall cost of die casting materials. The use of recycled metal materials not only reduces the need for raw materials, but also reduces the carbon footprint of the production process.

How to Calculate Die Casting Cost?

To calculate the cost of die castings, a number of factors need to be considered.

Including direct costs, indirect costs and energy consumption in the production process.

Below are the detailed steps and related references:

- Die casting direct cost

- Indirect Costs

- Energy consumption in the production process

- Other related costs

- Calculation formula

Die casting direct cost

Material costs

This includes the metal (e.g. aluminium, zinc, etc.) and other auxiliary materials (e.g. hinges, rods, etc.) used in the manufacture of the die casting mould.

For example, the direct cost of the mould is USD750.00, hinges are USD120.00, rods are USD500.00, and other miscellaneous items are USD500.00, for a total direct cost of USD2,500.00.

Cost of mould design and manufacture

The design and manufacture of moulds is an important part of die casting costs. This usually includes design costs, mould fabrication costs, etc.

Indirect Costs

Labour costs

This includes operator’s wages and related costs.

Indirect costs

Such as plant operating costs, equipment depreciation, etc.

Indirect costs are usually calculated as a percentage of direct costs.

Energy consumption in the production process

The die casting process requires a large amount of energy inputs, including electricity, cooling water, etc.

For example, high-pressure die casting (HPDC) processes consume large amounts of energy and are closely related to the use of materials (e.g., oil-based lubricants) and cooling water.

The use of new technologies (e.g. GIS technology) can optimise energy consumption and thus reduce production costs.

Other related costs

Scrap disposal and clean-up costs: The die casting process generates scrap, which needs to be cleaned up and disposed of.

Maintenance and preventive maintenance costs: in order to ensure the reliability of the machine, regular maintenance and preventive maintenance is required.

Calculation formula

The total cost can be estimated by the following formula:

Total cost = direct cost + indirect cost + energy consumption cost + other related costs

In this case, indirect costs can be calculated as a percentage of direct costs.

The above steps allow for a more comprehensive estimation of the cost of die castings.

It is important to note that the application of different processes and technologies may affect how specific costs are calculated and the results.

Is die casting cheaper than machining?

Whether die casting (Die Casting) is cheaper than machining (Machining) depends on specific production needs and conditions.

- Advantages of Die Casting

- Disadvantages of die casting

- Advantages of machining

- Overall conclusion

Advantages of Die Casting

Low cost of high volume production

Die casting is particularly suited to high volume production because the cost of the mould is spread over each part, the cost of a single part is significantly reduced.

In addition, die casting can reduce or eliminate subsequent processing steps, thus further reducing production costs.

High efficiency and good precision

Die casting can quickly produce products with complex geometry and high precision, and the surface quality is better than machining. This makes die casting more advantageous when high precision and consistency are required.

High material utilisation

There is less material waste during die casting and moulds can be reused, thus reducing unit costs.

High degree of automation

Die casting is usually highly automated, reducing labour costs and improving production efficiency.

Disadvantages of die casting

High initial investment

Although die casting in mass production at a lower cost, but the initial design and manufacturing cost of the mould is high, need a larger capital investment in the early stage.

Limited scope of application

For low volume production or simple shapes, machining may be more economical.

Surface treatment needs

Although die casting surface quality is better, but in some cases still need additional polishing or finishing, which will increase the additional cost.

Advantages of machining

High flexibility

Machining is suitable for the production of small quantities or simple shaped parts, without the need for upfront investment in moulds.

Flexible surface treatment

Machining can obtain a smoother surface by subsequent polishing, etc., which is suitable for products with high surface quality requirements.

Lower cost

For low volume production, machining is usually more economical than die casting.

Overall conclusion

If it is mass production and need complex shape and high precision products, die casting is usually cheaper than machining.

For small production runs or parts with simple shapes, machining may be more economical.

Die casting has a higher initial tooling cost, but its unit cost is significantly lower in high volume production, making it more suitable for long term mass production.

Whether die casting is cheaper than machining therefore depends largely on factors such as the size of the production, the complexity of the product and the need for subsequent machining.

If the production requirements fulfil the conditions for the advantages of die casting, die casting may be the more economical choice; otherwise, machining may be more suitable.

By the end

This article has briefly described the different factors that contribute to the high cost of die casting and how to optimise these factors. Before you choose die casting as the sheet metal manufacturing process for your project, you should be aware of several factors that play an important role in the cost of the process. Common factors that you must understand how to adjust relate to the materials, processes, and tooling involved.

Do you have questions about your process or how to optimise it?

Please feel free to contact Haichen’s technical team for a detailed answer.