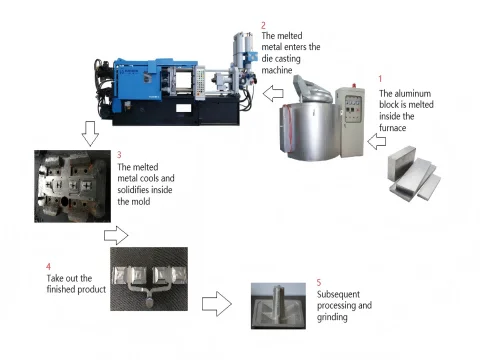

For aluminum road stud die-casting machines, cold chamber models should be selected, combined with four-chamber molds and automated units.

Which can efficiently produce road studs that meet the requirements of reflection and weather resistance.

In the automated production line of road spike die-casting machines, to achieve robot part picking and inspection in high-temperature environments, multiple aspects.

When choosing a die-casting machine for the aluminum road spike mold, Haichen needs to consider several factors, including injection energy, mold cavity capacity, clamping force, and mold installation dimensions.

When producing aluminum road markings, cold chamber die-casting machines are usually used because aluminum has a high melting point and needs to be injected under high pressure.

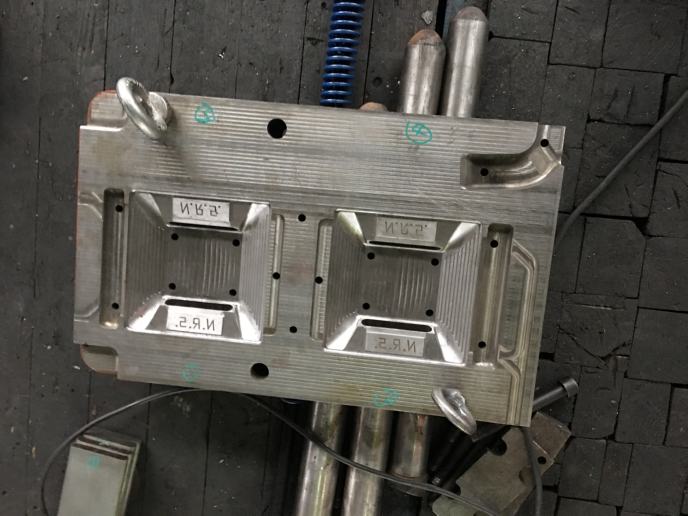

Aluminum Road Stud mould

There are several factors to consider when choosing a die casting machine for aluminum road stud mould, including injection energy, chamber capacity, clamping force, and mold installation size.

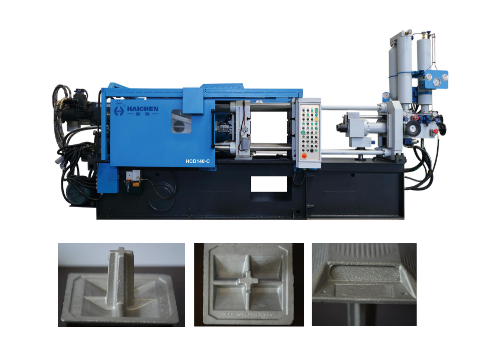

According to the different production requirements and size specifications of the customers, Haichen has designed 2-cavity and 4-cavity aluminum dowel die-casting molds respectively.

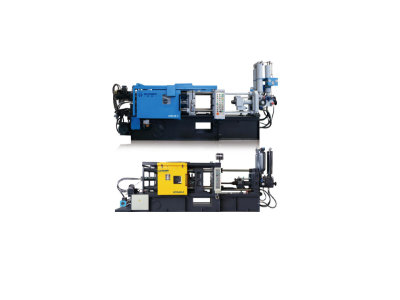

The customer can also choose to equip 200-ton and 300-ton cold chamber die-casting machines.

Road stud mold design

Once the material has been chosen, Haichen skilled design team of the road stud manufacturer takes immediate action to carefully design the shape, dimensions and internal structure of the road stud based on different application scenarios and traffic norms.

CAD software and precision machinery are used to create detailed prototypes and molds.

Make aluminum road stud mould

The fabrication of an aluminum road stud mold involves multiple steps and material selection.

Here are the details about aluminum road nail molds:

- Mold material selection

- Mold manufacturing process

- Application of molds

- Mold maintenance and maintenance

Mold material selection

- Aluminum alloy

- Tungsten carbide

- Tungsten carbide

- Cold work steel

- H13 Steel

Aluminum alloy

Although aluminum alloy has the characteristics of light weight, good thermal conductivity and strong corrosion resistance.

Its strength is low and it cannot withstand the effects of high temperature and pressure.

Therefore, aluminum alloy molds are suitable for low-pressure, low-temperature, low-speed hot forging and hot extrusion processing.

Tungsten carbide

Steel is especially suitable for use in high temperature and high pressure environments due to its high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance and a series of excellent properties.

Tungsten steel retains a high hardness at a temperature of 500°C and a high hardness at 1000°C.

Cold work steel

For aluminum stamping dies, it is recommended to use cold work steels, such as powder steels such as V10, V40, V4, etc., as well as materials such as Cr12MoV, SKD11, D2, DC53, GOA, etc.

These materials have excellent machinability, good thermal stability, good polishing properties and sufficient surface hardness and wear resistance.

H13 Steel

The material suitable for aluminum extrusion die should have basic properties.

Such as high yield strength and hardness at high temperatures, excellent fracture toughness, and high tempering resistance.

H13 steel performs well in high-temperature and high-pressure environments.

And is able to withstand the thermal fatigue caused by high temperature action and repeated heating and cooling.

Mold manufacturing process

Cast aluminum road studs usually use a permanent mold casting process.

First, the upper and lower dies are combined, and then the liquid aluminum is poured into the mold.

And after cooling, the aluminum road studs are obtained.

The surface treatment of the mold is also important, and it is often anodized to enhance corrosion resistance and hardness.

Application of molds

Aluminum road stud molds can be used to produce products with complex shapes

Such as rotary molds, which are capable of producing complex polyhedral shapes.

In practical applications, aluminum road nail molds are not only used for casting aluminum products.

But also for casting other metals such as copper.

Mold maintenance and maintenance

Aluminum molds require regular maintenance to maintain their accuracy and longevity.

They are lighter than steel molds, but they require regular inspection and maintenance.

Aluminum Road Stud mould material——H13 steel

H13 tool steel has excellent application performance in aluminum molds, and its performance characteristics and application fields are as follows:

- High hardenability and resistance to hot cracking

- Abrasion resistance and heat fatigue resistance

- High strength and hardness

- Oxidation and corrosion resistance

- Excellent comprehensive mechanical properties

- Wide range of applications

High hardenability and resistance to hot cracking

H13 die steel has extremely high hardenability and is able to withstand long-term operation at high temperatures without breaking and deformation.

This characteristic makes it excellent in high-temperature and high-pressure environments such as aluminum extrusion and aluminum die-casting.

Abrasion resistance and heat fatigue resistance

H13 die steel has good wear resistance and can maintain a long service life even under high load and high friction conditions.

In addition, it has excellent thermal fatigue resistance and is able to remain stable in alternating heating and cooling cycles.

High strength and hardness

The hardness of H13 die steel can reach 55HRC after heat treatment, which has high strength and hardness, so that it can still maintain good working performance at high temperatures.

Oxidation and corrosion resistance

The role of aluminum in steel significantly improves the oxidation resistance and corrosion resistance of H13 die steel.

For example, the addition of 6% aluminum can make steel oxidation resistant below 980°C, and even better when used with chromium.

Excellent comprehensive mechanical properties

H13 die steel not only has high hardness and strength, but also has good toughness.

So that it can maintain excellent performance in high temperature, high pressure, high strength and high wear environment.

Wide range of applications

H13 die steel is widely used in the manufacture of die-casting molds for aluminum, zinc, and copper alloys, as well as plastic molds and other high-wear-resistant, high-strength tools.

Especially in the fields of aluminum extrusion molds, aluminum die-casting molds.

H13 mold steel prolongs the service life of the mold and reduces the risk of damage due to its excellent hardness and wear resistance, thermal fatigue resistance and good toughness.

Die casting machine for Road Stud mould

Choosing the right die casting machine for aluminum road studs requires a combination of factors to ensure that the equipment can meet production needs and ensure product quality.

Here are the detailed analysis and recommendations:

- Product design requirements

- Production capacity and efficiency

- Ease of operation and maintenance costs

- Die Casting Machine Type

- Clamping force and mold size

- Degree of automation

Product design requirements

The size, shape, material and quantity of aluminum road studs are an important basis for choosing a die-casting machine.

Aluminum road nails usually require high precision, high stability, and high clamping force to ensure the dimensional accuracy and surface finish of the product.

Production capacity and efficiency

Depending on the production quantity and cycle demand of aluminum road studs, multiple or high-speed die casting machines can be selected to improve production efficiency.

For high-volume production, the use of high-speed die casting machines can significantly increase throughput.

Ease of operation and maintenance costs

Choosing a die casting machine that is easy to operate and low maintenance can reduce production costs and improve market competitiveness.

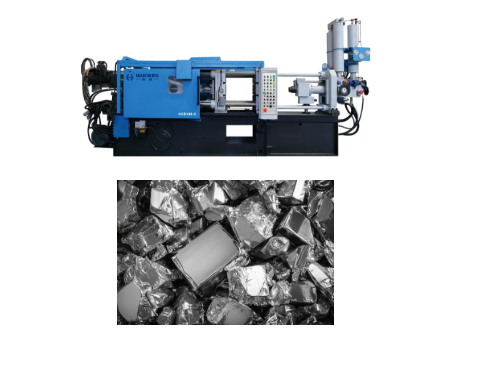

Die Casting Machine Type

Aluminum road nails are usually used in cold chamber die casting machines because cold chamber die casting machines are suitable for high melting point alloys.

Such as aluminum and can provide higher compressive strength and product integrity.

Clamping force and mold size

The clamping force of the aluminum road nail should be greater than the theoretically calculated expansion force to prevent the splashing of the molten aluminum.

And ensure the locking of the parting surface of the mold, so as to ensure the dimensional accuracy of the casting.

Degree of automation

Choosing a die casting machine with a high degree of automation can reduce manual intervention, increase output and reduce labor costs.

Haichen Die casting machine

Haichen is a reputable supplier and ensures that foundries can provide comprehensive after-sales service, including professional installation.

Commissioning and maintenance services, as well as free repair and technical support during the warranty period.