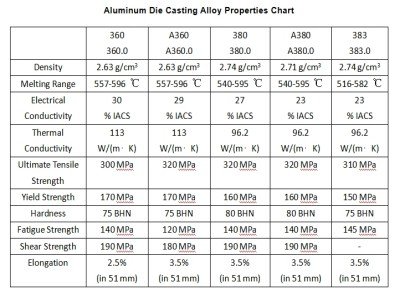

Die casting material properties refer to the properties exhibited by metal materials during the die-casting process, such as melting point, fluidity,etc.

These characteristics of the die casting used metal die casting materials determines greatly the quality and performance of the end piece.

This report is about the essential characteristics of the materials used in die casting and how they relate to the die casting and what is produce at the end.

This article will explore the key properties of die – casting materials and how they impact the casting process and part performance.

Die Casting Material Properties

- Melting Point

- Flowability

- Thermal Conductivity

- Strength and Hardness

- Shrinkage

- Ductility

Melting Point

Metals utilized within a die casting should possess a relatively low melting point. This ensures that the metal can both be melted and solidified within the die at a faster rate. This increases the overall cycle time efficiency within the casting process.

Flowability

Materials used should exhibit a favorable flowability. This phenomenon is critical in mold cavity filling and even more so in intricate and thin walled geometries. Enhanced flowability is the key in bubble and void elimination and promotes more uniform and defect-free castings.

Thermal Conductivity

The rate at which the molten metal cools within the die is fundamentally influenced thermal conductivity. This is critical as it determines the microstructure and mechanical properties of the casting.

Strength and Hardness

The wear resistance and mechanical load one is capable of applying to a die casting is dictate by the strength and hardness of the die material use in the casting process. This is particularly important in components subjecte to mechanical load.

Shrinkage

The dimensional accuracy and surface finish of a die casting is largely influenced by the solidification shrinkage of the material. The fewer the deformations one experiences, the more shrinkage one is said to possess. Materials are always desire that improve deformation resistance and dimensional stability.

Ductility

Ductility is require in the casting in order for it to survive the stresses of demolding from the mold without breaking and cracking. More forgiving and ductile materials have much less defects.

Impact of Material Properties on the Die-Casting Process

- Melt Temperature:

- With zinc alloys (380-420°C), there is 30% less energy used than with magnesium alloys (620-680°C).

- Mold Temperature:

- 150-200°C is the temperature range for aluminum alloys to avoid cold shuts while magnesium alloys are in 200-300°C to minimize oxidation.

- Injection Speed:

- Magnesium alloys is set at > 45 m/s (high fluidity) while aluminum alloy is set at 30-40 m/s.

- Shrinkage Compensation:

- Solid aluminum alloys deflect 1.2% under gravity therefore the mold design must initially be enlarged.

Haichen Machinery: Expert in Improving Die-casting Material Performance

- Advanced Control System and Quality Assurance

- Die casting material properties and solutions

- Market Competition and Customer Support

Advanced Control System and Quality Assurance

Haichen die casting machines apply modern systems and methods of machine-controlled die casting to achieve controlled casting injection pressure and speed, thus, enhancing casting quality and consistency.

Die casting material properties and solutions

We understand that die-casting materials’ properties such as fluidity, strength, and melting point influence the quality of die castings. Therefore, we strive to deliver die casting solutions tailored to different material properties.

Market Competition and Customer Support

Performance optimization of die casting machines enables our customers to maintain a competitive position, particularly in the die casting industry of aluminum alloys, zinc alloys, and magnesium alloys.

HAICHEN Die Casting Materials

High – Quality Alloys

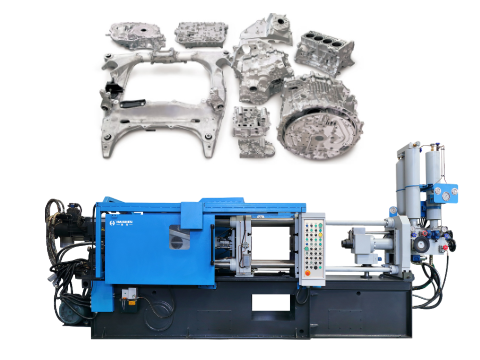

HAICHEN offers a range of high – quality die – casting alloys, including aluminum, zinc, and magnesium. These alloys are engineered to provide optimal mechanical and thermal properties for various applications. For example, HAICHEN’s aluminum alloys are optimized to have good fluidity, anti – sticking, and corrosion resistance, making them ideal for automotive and aerospace components.

Customized Solutions

HAICHEN provides customized material solutions to meet the specific needs of our customers. Our team of experts can help select the right alloy based on the desired properties and application requirements. Whether you need high – strength components or lightweight parts with intricate details, HAICHEN can provide the appropriate material solution.

Technical Support

HAICHEN offers comprehensive technical support to assist with material selection, process optimization, and troubleshooting. Our goal is to help our customers achieve high – quality results and maintain efficient production processes.

Common die casting materials include aluminum alloys, zinc alloys, magnesium alloys, and copper alloys. Each of these materials has unique die casting properties that make them applicable for varying purposes.

Optimizing the die casting process is vital for enhancing quality and reducing production costs. Understanding material properties is vital for die casting process optimization.