The die casting materials used are various, including aluminum alloy, zinc alloy, magnesium alloy copper alloy, etc. Each of these materials has its own unique properties and application areas.

Each material has unique properties and advantages that make them more suitable for specific applications. For example, aluminum alloys are widely used in automotive and aerospace applications because of their lightweight and high strength; zinc alloys are used in the manufacture of furniture fittings and hardware because of their good castability and mechanical properties; and magnesium alloys are becoming more and more popular for high-end applications because of their lightweight and high strength-to-weight ratio.

Die casting is a manufacturing process that uses molten metal to produce parts by forcing it into a mold cavity under pressure. Different materials can be used for die casting, each with its own properties and applications. Here are the applications of different die casting materials.

The applications of different die casting materials

- Aluminum Alloy

- Magnesium alloy

- Zinc alloy

- Copper alloy

- Lead alloy

Aluminum Alloy

Die casting Aluminum alloys (such as alloys 380, 360, 390, and 413) are popular in the automotive, aerospace, and other industries due to their low viscosity and excellent mechanical properties.

Aluminum alloy die castings are widely used in the automotive, appliance, aerospace, machinery, and other industries, with excellent corrosion resistance, high strength-to-weight ratio, and outstanding EMI and RFI shielding properties.

Aluminum alloy die casting in the automotive field amounted to 80%, motorcycles and through the machine and other equipment such as the engine and other core parts are also mainly made of aluminum alloy die casting.

Magnesium alloy

Magnesium alloys (such as AZ91D) have high fluidity and good castability, which reduces porosity during mold filling and makes them suitable for parts with complex designs and high corrosion resistance.

Magnesium-based alloys are suitable for the manufacture of lightweight components in automotive, aerospace and electronic equipment.

In addition, magnesium-based alloys are used in the manufacture of fishing gear frames as an alternative to plastic and aluminum components to reduce weight and maintain excellent density and surface quality.

Zinc alloy

Die casting Zinc-based alloys are very fluid in the molten state and can be cast into very complex shapes. Zinc-based alloys are often used in the manufacture of parts that require high precision and smooth surfaces.

The one alloys are often used for parts that require high precision and smooth surfaces, such as small hardware, decorative items, etc.

Zinc-based alloys have a linear shrinkage. Z

This alloys have a linear shrinkage of approximately 9 to 13 x 10-6 inches per inch-Fahrenheit and low casting temperatures (750-800°F), which allows for high productivity.

Copper alloy

Copper-based alloys, such as brass and silicon brass, are commonly used in the manufacture of parts that require corrosion resistance and strength, such as pipes, electrical components and marine parts.

Brass contains copper, zinc, tin and lead, which improve its corrosion resistance and workability. Casring Silicon brasses provide a higher level of corrosion resistance. Silicon brass offers increased strength and corrosion resistance. Silicon brass provides increased strength and corrosion resistance.

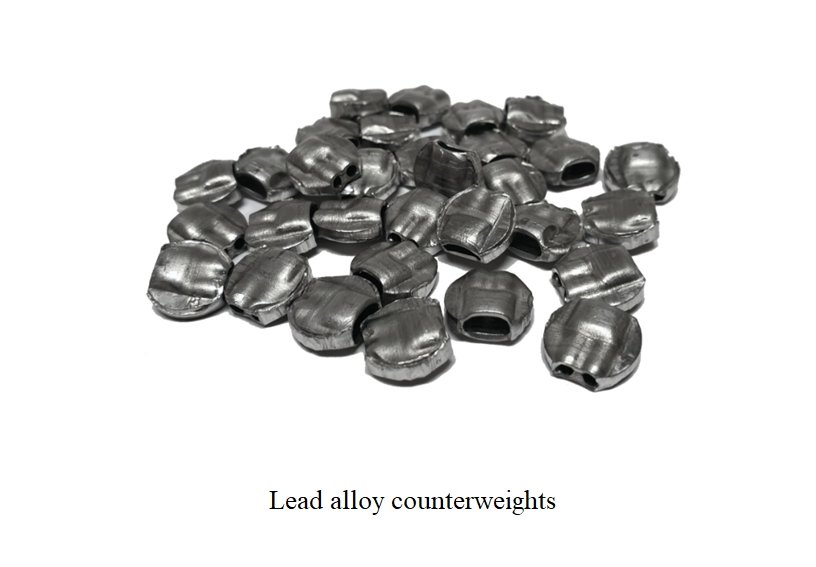

Lead alloy

One of the main applications of lead alloys is for lead-acid batteries, which is one of the most important uses of lead alloys. Components such as grids, posts and connecting bars in lead-acid batteries are manufactured using lead alloys because of their good electrical conductivity and corrosion resistance.

In addition, lead alloys are used in building construction materials such as plates, pipes and seals because of their relative inertness to the atmosphere.

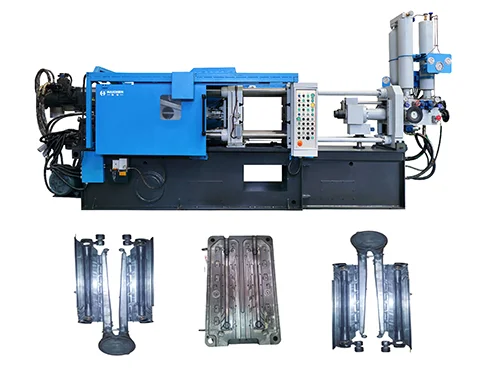

Haichen Machinery has rich experience in producing die casting products of different die casting materials. We can give you professional technical support from choosing raw materials, customizing molds, selecting molds to after-sales service. If there is any demand about die casting machine and die casting molds, welcome to visit our website to know the production information of different products.

Haichen die casting machine

At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.

What is the Process of Aluminum Die Casting?

Aluminium die casting is a highly efficient manufacturing process employed to produce intricate, high-quality metal components. This technique involves injecting molten aluminium into a mould cavity under high pressure, thereby ensuring precision and consistency in part production.

For manufacturers aiming to achieve superior product quality while maintaining production efficiency, understanding the detailed steps and significance of each stage within the aluminium die casting process is paramount.

This article provides a comprehensive overview of the aluminium die casting process, explaining each step and its significance in delivering high-quality components.

By mastering these steps, manufacturers can optimise production workflows, minimise defects, and enhance the overall quality of their parts.