Die casting mold cost optimization strategy includes material selection, optimize mold design, structural topology optimization, etc.

The cost optimization strategy of die casting molds involves material selection, design optimization, maintenance and reuse, automation, lean production, and the balance of comprehensive performance and cost. Through scientific and reasonable planning and implementation of these strategies, it can be significantly reduce the manufacturing cost of die casting molds. And improve the production efficiency and product quality.

- Material selection

- Mold design optimization

- Structural topology optimization

- Mold maintenance and reuse

- Comprehensive consideration of performance and cost

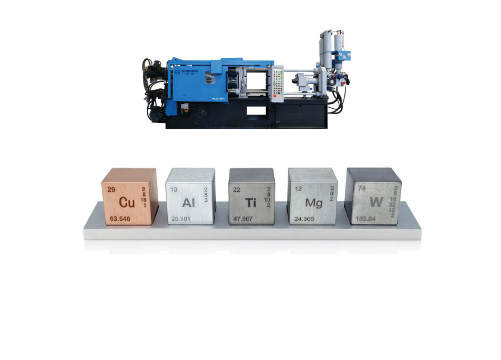

Material selection

Core principles of material selection: balancing cost and performance

The choice of materials is one of the important factors affecting the cost of die casting molds. Although high-quality materials have a higher initial cost, they can extend the life of the mold, thereby reducing long-term costs.

For example, the use of high-strength alloy steel (such as H13) can improve the durability and thermal fatigue resistance of the mold, especially for the production of high-precision and complex parts.

In addition, by optimizing material utilization and reducing unnecessary waste, it can effectively reduce the costs.

Prioritize performance and lifespan

- Mold materials must meet requirements for high-temperature strength, wear resistance, and thermal fatigue resistance to avoid mold failure due to material failure.

- For example, components that come into direct contact with molten metal (such as the mold cavity) should be made of high-quality heat-resistant steel (such as H13, 3Cr2W8V, and Cr12MoV) and undergo a hardening treatment to extend their lifespan.

Large-Scale Production

Although the initial cost of high-performance materials (such as H13 and 5CrNiMo) is higher, they can significantly extend mold life and reduce unit costs.

Small-Scale Production

Lower-cost materials (such as 40Cr and 30CrMnSi structural steel) can be used to avoid excessive investment.

Material properties and process requirements

- Thermal management performance: Prioritize materials with good thermal conductivity (such as copper alloys) to shorten cooling time and improve production efficiency.

- Machinability: Select easy-to-machine materials (such as P20 tool steel) to reduce manufacturing difficulty and processing costs.

- Recyclability: Aluminum and zinc alloy mold materials have high recycling rates, which can reduce long-term material costs.

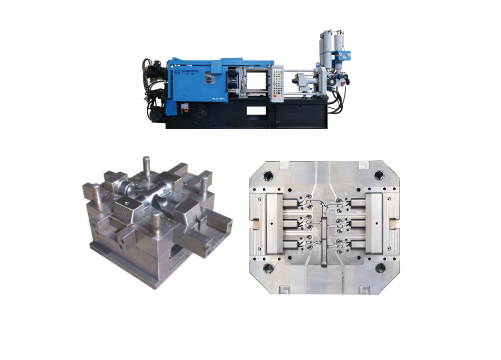

Mold design optimization

The complexity of mold design directly affects the cost. Simplifying mold design and reducing complex geometric shapes and high-precision requirements. It can reduce mold manufacturing costs.

For example, the use of multi-cavity mold design can produce multiple parts in one injection. Thereby improving production efficiency and reducing the cost of a single part.

In addition, the reasonable setting of parameters such as mold wall thickness, rib distribution, and cooling channels can optimize mold performance, reduce production cycle and scrap rate.

Improve Production Efficiency with Multi-Cavity Molds

- Multi-cavity molds can produce multiple parts in a single run, significantly reducing unit costs.

- They are particularly suitable for high-volume production. While the initial investment is higher, costs are mitigated through economies of scale.

- For example, modular mold designs allow for rapid maintenance and configuration adjustments, improving mold utilization.

Simplify Mold Structure and Design

The overall structure of a die casting mold can be summarized as a mold base, forming cavity (including cavity and core), gating system, cooling system, venting/discharging system, and ejection system, supplemented by standard components such as positioning, locking, and sealing.

Avoid overly complex geometric features (such as deep cavities and sharp corners) and reduce the need for additional features.

Such as slides and ejector pins. Simplifying the design reduces machining complexity, cycle time, and material consumption. Also, loosening tolerances and increasing draft angles in non-critical areas can extend mold life.

Optimize the Design Process with Digital Simulation

Using mold flow analysis software to simulate metal flow and solidification processes. You can predict defects and optimize the design of gating systems, cooling channels, and other components.

Virtual testing reduces the number of physical mold trials, shortening development cycles and reducing trial-and-error costs.

Structural topology optimization

Structural topology optimization is an effective cost optimization method.

By using the variable density method to perform topological optimization design on the static mold, dynamic mold, and stretching mold, it can be significantly reduce the mold weight.

While maintaining the necessary stress and deformation levels. For example, a study successfully reduced the total weight of the three main mold plates from 74.68 tons to 66.35 tons. By optimizing the model and constraints, achieving a weight reduction of 11.5%.

Lightweight design reduces material costs

Through topology optimization, we redistribute material and remove redundant material in low-stress areas, reducing mold weight while maintaining structural strength and rigidity.

Cooling system optimize improves efficiency and quality

- Using topologically optimized, efficient cooling structures replace traditional circular cooling channels.

- This achieves uniform temperature control, reduces defects, and shortens production cycles.

Structural-thermomechanical coupled optimization ensures mold life.

- Combining thermodynamics with structural topology optimization, support structures are integrated into the cooling structure.

- Resistant to high-pressure deformation during the die-casting process.

Mold maintenance and reuse

Regular maintenance and extending the service life of molds are key strategies to reduce long-term costs. Good maintenance can reduce the frequency of mold replacement and extend its service life.

In addition, it can be significantly reduce production costs by refurbishing or reusing old molds.

Regular preventive maintenance

Plasma cleaning (every 5,000 mold cycles), crack detection, and weld repair can extend the life of H13 molds to 150,000 mold cycles (from 80,000).

Materials and surface treatment

The use of heat-resistant tool steel combined with corrosion-resistant coatings (such as TD treatment) improves mold resistance to thermal fatigue and increases mold life by 2-3 times.

Design optimization supports reuse

- Multi-cavity mold design significantly increases single-run output with limited initial cost increases, thus reducing unit costs.

- Simplifying mold structure avoids complex features that make maintenance difficult, while also reducing machining allowances and reducing post-processing requirements.

Comprehensive consideration of performance and cost

When selecting materials and designing molds, it is necessary to balance the relationship between performance and cost.

For example, under the premise of meeting performance requirements, try to choose lower-cost materials and reduce material consumption through optimized design.

Optimize and simplify mold design structures

Reducing complex geometries (such as thin walls and undercuts) reduces mold manufacturing difficulty and cost without sacrificing product quality.

Process parameter optimization

Injection parameters: Adjusting injection speed, pressure, and other parameters can reduce defects.

Maintenance and life extension

Mold refurbishment: Regularly repair worn areas to avoid complete replacement.

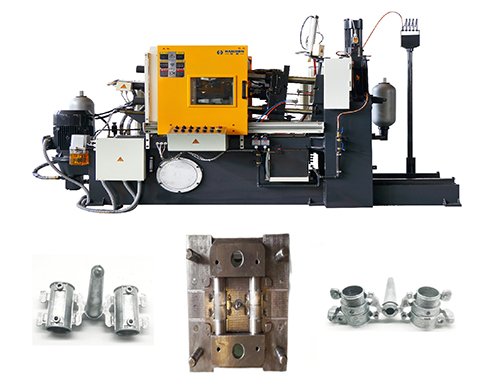

Haichen die casting mold

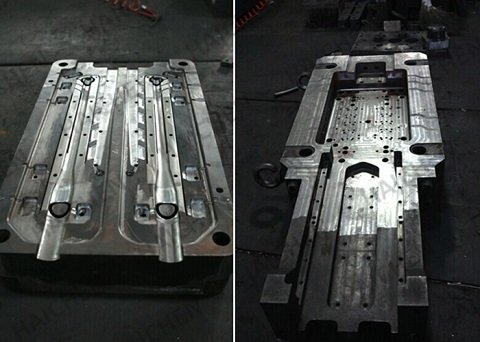

Haichen die casting mold possesses a complete technical system. From structural simulation, material selection to mold processing, assembly and debugging. Haichen’s mold solutions have widely covered multiple fields such as automotive, electronics, and industry. For example, aluminium alloy frying pan mold, aluminum radiator mold and so on. It can provide customized mold design and production services according to the specific needs of different industries.

Practical solutions for die casting mold cost optimization strategy

- Redesign for an Aluminum Housing

- Process Improvement for Zinc Parts

Redesign for an Aluminum Housing

A customer needed a mold for a thin-wall housing. The first design was complex and costly. HAICHEN engineers suggested a simpler slide design. We also changed some tight corners to gentle curves. The new mold cost 25% less to make. It also ran with less wear.

Process Improvement for Zinc Parts

One zinc fittings maker had high mold repair costs. HAICHEN found poor cooling in key areas. We redesigned the cooling channels and added a coating. The mold now runs cooler and lasts longer. Repair costs dropped by 60% per year.

As a die casting machine manufactuer, HAICHEN looks at the full process. We know good molds need good machines. Our machines offer stable performance and precise control. This protects your mold from damage and wear. With HAICHEN, you get both the technology and the know-how for cost-efficient die casting.

Optimizing die casting mold cost requires smart choices at every step. Focus on simple designs, proper materials, and good maintenance planning. Real cases from HAICHEN prove that careful optimization cuts cost and boosts mold life. Partnering with an experienced maker like HAICHEN ensures your molds and machines work well together for the best return on investment.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine , die casting mold and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.