Die casting solution for Ladle ensures precise molten metal transfer with optimized temperature control and minimal oxidation.

Die casting is a precision manufacturing process used to produce high-quality metal parts with complex geometries and tight tolerances.

The ladle, a critical component in the die casting process, transfers molten metal from the melting furnace to the injection chamber of the die casting machine.

This article will explore the die casting solutions for ladles, highlighting the key considerations and best practices to ensure efficient and safe metal transfer.

Overview of Die Casting Process and its Synergy with Ladles

Die casting is a metal forming process that involves injecting molten metal under high pressure into a precision, reusable mold (die casting mold), followed by rapid cooling to obtain the final part. This process is particularly suitable for mass production of parts with complex shapes, thin walls, high dimensional accuracy, and stringent surface quality requirements, and is widely used in the automotive, consumer electronics, and aerospace industries.

In the entire die casting workflow, metal melting and transfer are the primary and critical steps. The ladle plays a crucial “bridge” role in this process, its performance directly affecting the metal state in subsequent injection stages and ultimately impacting the quality and consistency of the casting. An optimized ladle solution must deeply align with the core requirements of the die casting process regarding speed, temperature, and cleanliness.

Importance of Ladle in Die Casting

- Efficient Metal Transfer

- Consistent Metal Temperature

- Safety and Reliability

Efficient Metal Transfer

The ladle efficiently transfers molten metal from the melting furnace to the die casting machine, playing a crucial role in the process. Proper design and maintenance of the ladle can significantly reduce metal loss and improve overall production efficiency.

Consistent Metal Temperature

Maintaining a consistent temperature of the molten metal during transfer is essential for achieving high-quality castings. Ladles with proper insulation and thermal management can help maintain the metal’s temperature, reducing the risk of defects such as cold shuts and porosity.

Safety and Reliability

The ladle must be designed and operated with safety in mind. High-temperature operations require robust materials and construction to prevent leaks and spills, which can lead to serious accidents. Regular inspection and maintenance of the ladle are essential to ensure its reliability and safety.

Key Considerations for Die Casting Ladles

- Material Selection

- Ladle Design

- Thermal Management

- Automation and Safety Features

Material Selection

The material used for the ladle must withstand high temperatures and resist erosion and corrosion. Common materials include high-grade steel and refractory materials. The choice of material depends on the specific requirements of the molten metal being handle.

Ladle Design

The design of the ladle should facilitate easy pouring and minimize metal splashing and oxidation. Features such as a well-designed spout and proper ladle capacity can improve the efficiency and safety of the metal transfer process.

Thermal Management

Proper thermal management is essential to maintain the temperature of the molten metal. Ladles often include insulation and heating systems to maintain proper metal temperature while moving molten material.

Automation and Safety Features

Modern ladles often incorporate automation and safety features such as automatic pouring systems, temperature sensors, and emergency shutoff mechanisms. These features can improve the precision and safety of the metal transfer process.

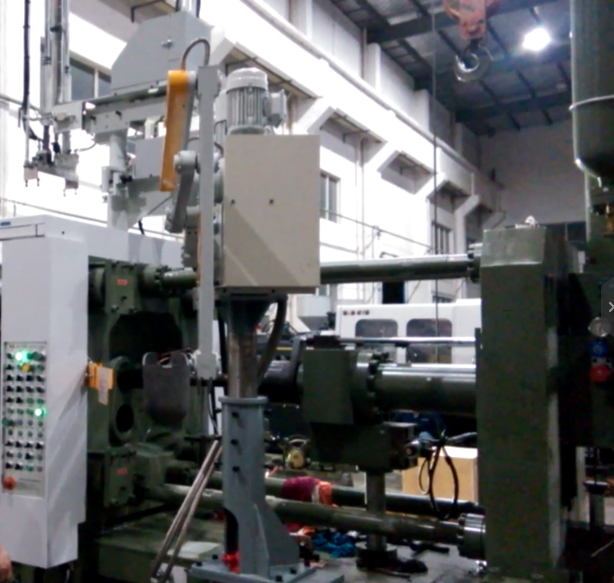

Integrated Ladle Operations

HAICHEN’s ladle solutions are designe for seamless integration with the die – casting machine. This integration ensures precise and consistent dosing, controlled by the machine’s central controller. The ladle settings can be programme directly on the machine’s interface, improving repeatability and reducing setup time.

Reducing Heat Loss

HAICHEN focuses on minimizing heat loss during the die – casting process. By preheating and holding the ladle, optimizing ladle management and operation, improving the permanent lining of the ladle, and using advanced heating technology, HAICHEN ensures that heat loss is effectively reduced.

HAICHEN: Your Partner in Die Casting Solutions

At HAICHEN, we specialize in manufacturing advanced die casting machines designed to meet the highest standards of precision and reliability. Our machines are equipped with efficient and safe ladle solutions to ensure consistent production quality and efficiency. Whether you are producing automotive parts, aerospace components, or other high-precision products, HAICHEN offers the tools and expertise to help you achieve your production goals.

Why Choose HAICHEN?

- Advanced Technology: Our die casting machines are equipped with state-of-the-art control systems and precision components to ensure high-quality production.

- Custom Solutions: We offer tailored machine configurations to meet specific production needs, including ladle design, material type, and production volume.

- Quality and Reliability: HAICHEN engineers manufacture machines to aerospace-grade standards, delivering 99.9% operational reliability with <0.1% unplanned downtime annually.

- Comprehensive Support: Our commitment to customer satisfaction includes comprehensive after-sales support, technical assistance, and maintenance services.

The ladle is a critical component in the die casting process, ensuring efficient and safe transfer of molten metal. Die casting solution for Ladle addresses key factors like material selection, optimized design, thermal management, and automation integration to enhance operational efficiency and safety.