Difference between cold and hot chambers die casting machine is the chamber kept insideor outside the furnace. Difference between cold and hot chambers machine: Insider is the hot chamber, and outside is the cold chamber. The chamber outside of furnace,so the chamber keep cold.

The hot chamber die casting machine as the chamber keep inside the furnace, so the chamber keep heating by melt alloy.Difference between cold and hot chambers machine, not just different chambers, also the material of machine use is different.

And The hot chamber heating temperature is lower than the cold chamber, so the hot chamber heating temperature just can melt zinc.

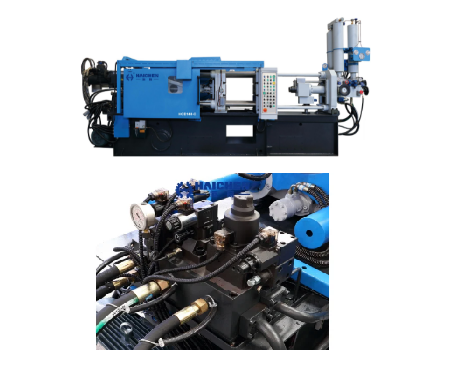

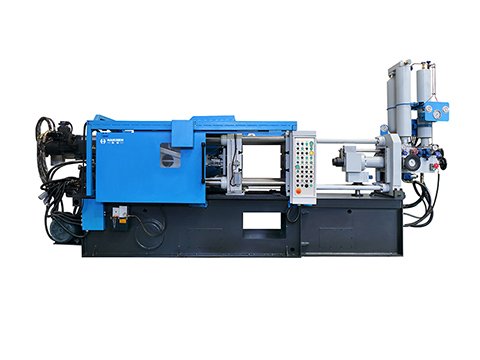

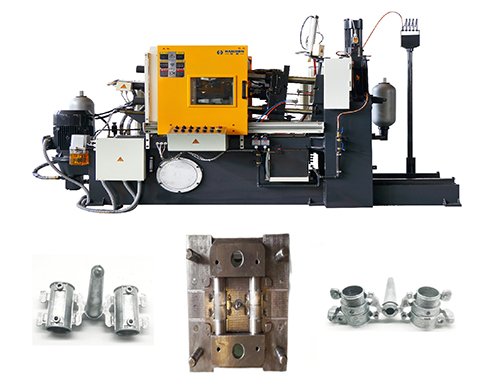

The most mainstream large horizontal die casting machine

- Cold chamber die casting machine

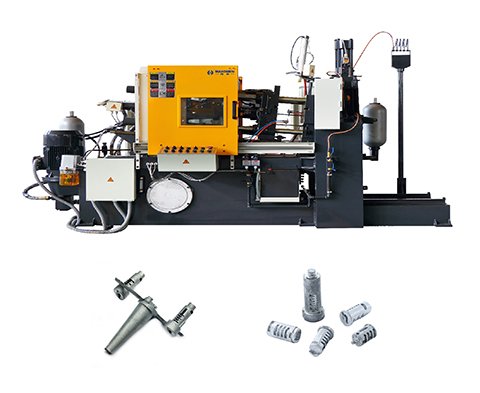

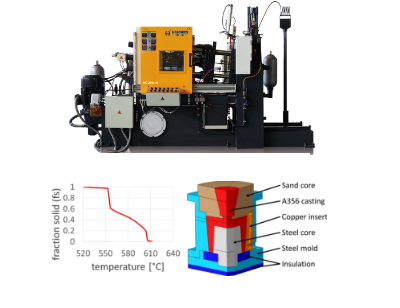

- Hot chamber die casting machine

There are two main types of die casting machines classified by the casting method of the pressure chamber.

cold chamber die casting machine and hot chamber die casting machine.

Cold chamber die casting machine

The die chamber of this type of die casting machine is separated from the molten metal holding furnace and does not have an automatic pouring system.

It usually requires manual or mechanical pouring of molten metal into the injection chamber for die casting.

Due to the high melting point of metals such as aluminum alloys, cold chamber die casting machines are more suitable for processing these materials.

Hot chamber die casting machine:

This type of die casting machine has a die chamber immersed in molten metal.

It usually with an automatic pouring system (gooseneck) that can directly introduce liquid metal from the holding furnace into the shot chamber for die casting.

Hot chamber die casting machines are mainly used for the processing of low melting point metals such as zinc alloys and magnesium alloys.

Working principle of cold chamber

- Preparation and pouring of molten metal

- Injection process

- Cooling and solidification

- Opening the mold and removing the casting

- Residual material processing

Preparation and pouring of molten metal

First, pour the molten metal liquid into the chamber (also called the feed barrel).

This step can be done manually or by other means.

Injection process

After the molten metal enters the chamber, the injection piston is driven by the hydraulic system to push the molten metal into the mold at high speed.

This process needs to be carried out while maintaining a certain pressure to ensure that the molten metal can quickly fill the mold cavity.

Cooling and solidification

After the molten metal is injected into the mold, the mold needs a cooling system to cool the molten metal so that it solidifies and forms.

The length of the cooling time depends on the type of metal material and the design of the mold.

Opening the mold and removing the casting

When the molten metal is completely solidified, the mold will open, and the die casting will remain on the moving mold.

Then the casting is pushed out of the mold by the ejection mechanism.

Residual material processing

During the injection process, the excess molten metal will be pushed into one side of the mold to form residual material cakes.

Which will be taken out with the casting.

Application fields of cold chamber

Cold chamber die casting machines are also used in building materials, hardware supplies and other fields to produce large-scale castings of non-ferrous metals such as aluminum, zinc, and copper.

These application fields demonstrate the importance and diversity of cold chamber die casting machines in modern manufacturing

- Automobile

- Aerospace

- Electronics

- Home appliances

- Communications

Automobile

Cold chamber die casting machines are used in the automobile industry to produce various parts and components.

Such as engine parts, car seat frames, and new energy vehicle battery packs.

For example:

HCD 200-C (200 tons):

Extrusion force 2000 kN, die-casting thickness range 200-580 mm, maximum casting volume 1.3/1.8 kg, suitable for small and medium-sized parts.

HCD880-C (880 tons):

Clamping force 880 tons, maximum casting volume up to 10.4 kg, suitable for larger engine parts.

HCC220 aluminum-magnesium alloy die-casting machine:

With a clamping force of 2200 kN and a maximum dry shot speed of more than 7 m/s, it is suitable for large castings in the fields of aviation, automobiles, etc., such as engine suspension brackets, etc.

For example:

HCD 200-C (200 tons):

Extrusion force 2000 kN, die-casting thickness range 200-580 mm, maximum casting volume 1.3/1.8 kg, suitable for small and medium-sized parts.

HCD880-C (880 tons):

Clamping force 880 tons, maximum casting volume up to 10.4 kg, suitable for larger engine parts.

HCC220 aluminum-magnesium alloy die-casting machine:

With a clamping force of 2200 kN and a maximum dry shot speed of more than 7 m/s, it is suitable for large castings in the fields of aviation, automobiles, etc., such as engine suspension brackets, etc.

Core technical features

Precision control:

Adopting hydraulic components from brands such as MITSUBISHI and Vickers, combined with servo control technology, it realizes closed-loop control of injection speed and pressure to ensure the density of castings.

Aerospace

The equipment is used in the aerospace field to manufacture high-precision parts such as aircraft shells.

Electronics

Cold chamber die casting machines are used in the electronics industry to produce high-precision 3C electronic products (such as mobile phone cases).

Home appliances

In the home appliance industry, cold chamber die casting machines are used to produce parts for home appliances.

Communications

Cold chamber die casting machines are also used in the manufacture of communication equipment, such as 5G communication equipment.

The working principle of the hot chamber

hot chamber die casting machine ruuning steps mainly includes the following steps:

- Heating the metal

- The molten metal is kept molten

- Injection process

- Cooling and solidification

- Mold opening and ejection

Heating the metal

First, the metal material is placed in the furnace inside the machine and heated to make it reach a liquid state.

The molten metal is kept molten

The molten metal is kept in an insulated crucible to ensure that it is always in a liquid state.

Injection process

When the mold is closed, the injection mechanism (usually a piston) injects the molten metal into the mold cavity through the gooseneck and nozzle.

This process is achieved by pressure generated by mechanical or compressed air.

Cooling and solidification

The molten metal cools and solidifies into the desired shape in the mold cavity.

Mold opening and ejection

After the molten metal solidifies, the mold is opened, the casting remains on the side of the moving mold, and then the ejector ejects the casting from the mold.

Application of hot chamber

It is mainly used to produce low melting point nonferrous alloy parts, such as zinc, lead, etc.

Its application field is very wide, covering the following main aspects:

- Automobile manufacturing

- Electronics industry

- Home appliances and daily hardware

- Instruments and meters

- Toys and household goods

- 3C industry

- Aerospace and medical devices

- Other industrial fields

Automobile manufacturing

Hot chamber die casting machine is very common in automobile manufacturing, and is often used to produce automobile parts, such as engine cylinder block, cylinder head, gearbox housing, etc.

In addition, it also plays an important role in the lightweight process of automobiles.

Electronics industry

Hot chamber die casting machine is also widely used in the electronics industry, used to produce the shell and internal parts of various electronic equipment.

Home appliances and daily hardware

So since hot chamber die casting machine can produce thin-walled castings with high appearance requirements.

And it has been widely used in home appliances, computers, communication equipment and daily hardware.

Instruments and meters

Because Hot chamber die casting machine also occupies an important position in the instrument and meter industry.

And is used to produce the shell and other parts of precision instruments.

Toys and household goods

As Hot chamber die casting machine is also widely used in toys, furniture appliances, building materials and hardware industries, which can meet the needs of these industries for high-quality die castings.

3C industry

And Including computers, communications and consumer electronics, hot chamber die casting machines are used to produce various precision parts in these fields.

Aerospace and medical devices

And Some high-end application fields such as aerospace and medical devices also use hot chamber die casting machines to produce key parts.

Other industrial fields

In addition, hot chamber die casting machines are also used in machinery, construction and other fields to produce various industrial parts.

Haichen Machine for Die Casting

Ningbo Haichen machinery was founded in 2005, Located in Ningbo, zhejiang, China. As we all know Ningbo is a port city, which is more convenient for export, cost of transportation is cheaper than other cities.

HAICHEN specializes in the production and sale of hot chamber die-casting machines, cold chamber die casting machines, servo die casting machines, magnesium alloy die casting machines and relative auxiliary equipment.

Like we have “HAlCHEN”‘s hot chamber as well as cold chamber die-casting machines have won the trust of our clients at home and abroad.

So this article focuses on the difference between cold and hot chamber machine, including the operating materials and applicable ranges of the two systems. It should be helpful for your production technology.