Differences Between Aluminum Die-Cast & Alloy Cookware include material composition, mechanical properties, application range, cost, and corrosion resistance.

When it comes to choosing cookware, understanding the differences between aluminum die-cast cookware and aluminum alloy cookware is essential. Both types offer unique advantages and are popular for their durability and performance.

In this article, we will explore the key differences between these two types of cookware to help you make an informed decision.

Differences Between Aluminum Die-Cast Cookware & Aluminum Alloy Cookware

- Material Composition

- Mechanical Properties

- Application Range

- Cost Considerations

- Corrosion Resistance

Material Composition

- Aluminum Die-Cast Cookware: Made from pure aluminum, this type of cookware is known for its excellent thermal conductivity and lightweight nature. It heats up quickly and evenly, making it ideal for various cooking methods.

- Aluminum Alloy Cookware: Composed of aluminum mixed with other elements like magnesium, manganese, and silicon, aluminum alloy cookware offers enhanced mechanical properties such as higher tensile strength and hardness. This makes it suitable for applications requiring higher durability.

Mechanical Properties

- Aluminum Die-Cast Cookware: While pure aluminum is lightweight and easy to handle, it has lower mechanical strength compared to aluminum alloys.

- Aluminum Alloy Cookware: The addition of other metals in aluminum alloys improves their mechanical properties, making them more resistant to wear and tear. This is particularly beneficial for cookware that will be used frequently or subjected to high temperatures.

Application Range

- Aluminum Die-Cast Cookware: Often used for everyday cooking needs, such as frying pans and baking trays, due to its lightweight and even heat distribution.

- Aluminum Alloy Cookware: Commonly found in professional kitchens and for specific cooking tasks that require higher strength and durability, such as pressure cookers and large pots.

Cost Considerations

- Aluminum Die-Cast Cookware: Generally more affordable due to the use of pure aluminum and simpler manufacturing processes.

- Aluminum Alloy Cookware: Tends to be more expensive due to the complexity of the alloying process and the enhanced properties it offers.

Corrosion Resistance

- Aluminum Die-Cast Cookware: Pure aluminum can be more susceptible to corrosion, especially in acidic or alkaline environments.

- Aluminum Alloy Cookware: The alloying process often improves corrosion resistance, making it more suitable for a wider range of cooking conditions.

Differences in Manufacturing Processes

The Differences Between Aluminum Die-Cast & Alloy Cookware are also clear in their core manufacturing processes. This directly affects the shape complexity, production speed, and cost.

- Die Casting Process

- Spinning/Stamping Process

- Process Impact on Performance

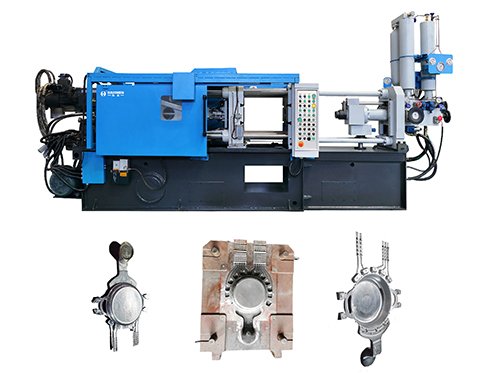

Die Casting Process

Aluminum die-cast cookware usually uses high-pressure die casting. Molten pure aluminum or alloy is injected into a steel mold under high pressure. It forms into the cookware’s shape quickly in one step. This process is good for making pots with detailed patterns, curved shapes, or built-in handles. The mold cost is high, but it is efficient for large production runs.

Spinning/Stamping Process

Many aluminum alloy cookware pieces use spinning (for round shapes) or stamping (for sheets). This process shapes aluminum plates or disks using mechanical force with molds. It is often used for simpler shapes (like straight-sided pots). The mold cost is lower, and it offers more flexibility for medium-scale production.

Process Impact on Performance

Die casting can create very even wall thickness and complex 3D structures. This helps heat spread evenly. Spun or stamped pieces might have tiny thickness changes at the seams. However, they can achieve a very smooth surface finish with later processing.

Differences in Surface Treatment and Durability

Surface treatment is key to improving cookware performance and lifespan. The Differences Between Aluminum Die-Cast & Alloy Cookware also show in the methods used and their results.

- Anodizing Treatment

- Ceramic and Teflon Coatings

- Durability and Care

Anodizing Treatment

This method is more common for aluminum alloy cookware. An electrochemical process creates a hard, dense layer of aluminum oxide on the surface. This greatly increases hardness, wear resistance, and corrosion resistance. The effect of hard anodizing on die-cast pure aluminum can differ due to its material properties.

Ceramic and Teflon Coatings

Both types of cookware can use these coatings. Good coating adhesion depends on the base material’s clean surface and microstructure. Die-cast surfaces are dense, providing a uniform base for coating. Alloy sheet surfaces can also achieve excellent adhesion after proper treatment.

Durability and Care

Hard-anodized aluminum alloy cookware has a very hard surface that resists scratches well. The durability of die-cast cookware relies more on its overall strength and the quality of its surface coating. For daily care, both types should avoid scratches from sharp metal utensils.

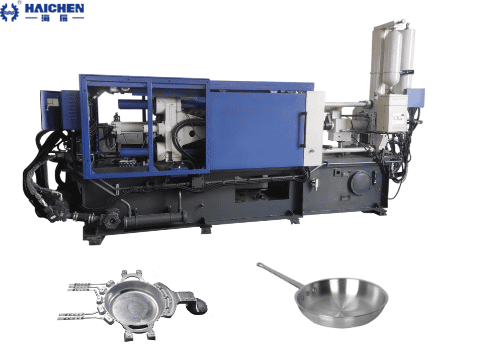

HAICHEN: Die Casting Machine Manufacturer

Known for its advanced die-casting technology, HAICHEN produces durable and efficient cookware solutions. Our machines ensure precise casting, resulting in products with excellent heat distribution and durability. HAICHEN’s commitment to innovation and quality makes them a reliable choice for both home cooks and professional chefs.

Case: Efficient Production of One-Piece Die-Cast Frying Pans

A cookware maker wanted to produce a one-piece aluminum deep fry pan. The pan had a handle with anti-slip patterns and a base with heat-spreading designs. They chose a HAICHEN 650-ton cold chamber die casting machine. The machine’s stable, high clamping force kept the large mold from deforming during injection. This produced pan bodies 28 cm in diameter with even walls (4mm bottom, 2.8mm side). The surface details were sharp and clear.

Choosing between aluminum die-cast cookware and aluminum alloy cookware depends on your specific needs. If you prioritize lightweight and affordable options with excellent heat distribution, aluminum die-cast cookware is a great choice. However, if you require higher strength and durability for more demanding cooking tasks, aluminum alloy cookware may be more suitable.