Different types of die casting process mainly have hot chamber die casting, cold chamber die casting, vacuum die casting and others.

Die casting is an efficient and precise metal casting method, which is widely used to produce high-quality parts. It by forcing molten metal under high pressure into a mold cavity, typically manufactured from hardened tool steel. The process generally involves five main stages: mold preparation and clamping, injection, cooling, ejection, and trimming.

The selection of die-casting processes requires a comprehensive consideration of material properties, production scale, quality requirements, and economic factors. Hot-chamber and cold-chamber processes remain the mainstay for mass production, while specialized techniques such as vacuum casting, squeeze casting, and semi-solid casting meet the demand for components with higher integrity in high-requirement applications.

According to different requirements and material properties, die casting can be divided into many types. Each of which has its own unique application scenarios and advantages.

Hot Chamber Die Casting

Definition

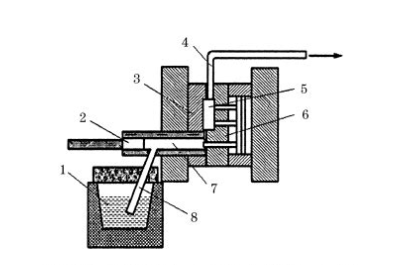

Hot chamber die casting is one of the most common die casting processes, also known as gooseneck casting. It works with hot chamber die casting machine machine.

Process

- In this process, the molten metal is in direct contact with the melting system and enters the mold cavity through a gooseneck tube.

- The injection mechanism is permanently immersed in the molten metal bath, allowing for rapid cycling times typically ranging from 30 to 60 seconds per part .

- The process begins with the piston in the raised position, which allows molten metal to fill the shot chamber.

- As the piston moves downward, it forces the metal through the gooseneck and nozzle into the die cavity.

- After sufficient cooling time, the die opens and the casting is ejected, completing the cycle.

Material

This process is suitable for low melting point metals such as zinc, magnesium, tin and lead.

Characteristics

Its advantages include fast mold filling, high production efficiency and low equipment cost.

But it is necessary to avoid using high melting point metals to prevent damage to the pump.

Cold Chamber Die Casting

Definition

Cold chamber die casting is another major die casting process. The cold chamber die casting machine separates the furnace from the injection mechanism, and each cycle requires manual scooping or automatic delivery of molten metal into the injection chamber.

Process

- In this process, molten metal is poured from an external melting container into a cold chamber. And then it inject into the mold cavity under high pressure.

- The operation sequence begins with pouring molten metal into the injection chamber of the cold chamber die casting machine.

- The hydraulic driven piston advances forward, pressing the metal into the mold cavity at high speed and high pressure.

- After the mold cavity is filled, pressurization is usually applied to compensate for solidification shrinkage and ensure dimensional accuracy.

- The solidified casting is ejected after a specified cooling time, and the process is repeated.

Material

It is suitable for alloys with higher melting points, such as aluminum, brass, and copper based alloys.

Characteristics

- The advantage of this method is that it can handle metals with higher melting points while reducing the risk of metal oxidation.

- But the equipment cost is higher and the production speed is slower.

- Cold chamber die casting has greater flexibility in alloy selection and can produce components with excellent mechanical properties.

- Its cycle time is slower and energy consumption is higher. Due to the separation of melting and injection systems.

Vacuum Die Casting

Definition

Vacuum die casting is an advanced casting process that combines vacuum technology with traditional high-pressure die casting.

By evacuating the mold cavity before or during metal injection, the air and gas in the mold cavity are removed, allowing the molten metal to flow into the mold under low pressure, thereby significantly reducing the occurrence of pores, oxidation and other defects.

Process

- Mold Preheating: Heat the mold to the set temperature.

- Evacuation: Activate the vacuum pump before injection to reduce the mold cavity pressure to below 50 mbar (approximately 1/20 of atmospheric pressure), or to a lower high vacuum (<150 mbar).

- Molten Metal Injection: Rapidly inject molten metal into the evacuated mold cavity under high pressure (typically 80–150 MPa).

- Pressure Holding and Cooling: Maintain pressure for a specified period of time to allow the metal to solidify and reach thermal equilibrium.

- Vacuum Release and Mold Opening: After vacuuming is completed, the mold is opened and the casting is removed.

Characteristics

- Significantly Reduced Porosity and Gas Inclusions: After vacuuming, virtually no gas is trapped within the casting, significantly reducing porosity.

- Improved Mechanical Properties: Reduced defects improve the strength, elongation, and impact toughness of the casting, particularly when using low-iron aluminum alloys.

- Better surface quality: The vacuum environment inhibits oxidation, making the surface smoother and more delicate, and post-processing steps (such as spraying and machining) easier to achieve.

Low Pressure Die Casting

Low pressure die casting is a process that injects molten metal into a mold at a relatively low pressure. And it usually uses to produce large or thin-walled parts.

The advantages of this process are that it can reduce defects caused by metal flow and reduce energy consumption.

Semi-Solid Die Casting

Semi-Solid Die Casting is a process that uses metal to inject into a semi-solid (paste) state, which can improve the mechanical properties and surface quality of parts.

This process is particularly suitable for parts that require high strength and wear resistance.

Squeeze Casting

Squeeze casting is a process that injects metal into a mold by applying higher pressure, which can further increase the density and strength of the part.

This process is often used for key components in the aerospace and automotive industries.

Gravity Die Casting

Gravity die casting is a process that uses gravity rather than high pressure to inject metal into a mold. It is suitable for producing small parts with simple shapes.

Different types of die casting processes have their own advantages and disadvantages, and choosing the right process depends on factors such as material properties, part geometry, size, and production requirements. For example, hot chamber die casting is suitable for small parts with low melting point metals, while cold chamber die casting is more suitable for large parts with high melting point metals.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.