Features of die casting ladle include high temperature resistant material manufacturing, precise pouring gate design and ergonomic design for easy operation.

The ladle is an indispensable part of the die casting process. It is responsible for safely and accurately transporting the molten metal from the holding furnace to the cavity entrance of the die casting mold. The operator uses it to control the amount of metal injected each time, which is critical to ensure that the entire die casting process runs smoothly and efficiently.

Because the ladle directly affects the quality of the final casting (such as reducing defects such as pores and cold shuts) and the efficiency of the production line, it is particularly important to understand its specific structure (such as pouring cup, main frame, pouring nozzle, handle and lever mechanism, temperature control function, etc.) and practical use points.

In this article, we will discuss the main structural features of the die casting ladle in detail and explain their practical role in the die casting process.

Definition and core role of die-casting ladle

The die-casting ladle is a tool used in the foundry to hold, transport and pour molten metal. As a key device connecting the smelting furnace and the die-casting mold, its operation effect will directly affect the quality of the casting and production efficiency.

Specifically, its value is mainly reflected in three aspects:

- Precise transfer of molten metal

- Guarantee the quality of castings

- Adapt to automated production

Precise transfer of molten metal

The ladle needs to accurately transfer molten metal such as aluminum, zinc or magnesium alloy from the holding furnace to the pressure chamber or mold cavity of the die-casting machine. In cold chamber die casting, this work usually needs to be completed with the help of a robotic arm, and the pouring accuracy error needs to be controlled within ±2%.

Guarantee the quality of castings

By reducing the oxidation of the molten metal during the transfer process, the mixing of impurities and the loss of heat, the ladle can effectively reduce the risk of defects such as pores and cold shuts in the casting. For example, its scraping edge design can remove the oxide layer on the surface of the molten metal, while the ceramic lining can maintain the metal temperature and prevent iron contamination.

Adapt to automated production

In the robotic pouring unit, the ladle can achieve high-precision quantitative pouring to ensure the consistency of the production rhythm. Its handle and lever mechanism support the robot arm for stable operation, while weight markings help control the amount of each pour.

The features of die casting ladle

- Material resistance

- Insulation

- Pour spout design

- Ease of use

- Temperature resistance

- Application in HAICHEN’s Die-Casting Solutions

Material resistance

In terms of material selection, we usually use graphite, cast iron or special alloys, which can withstand high-temperature melts above 1300℃ and effectively resist the erosion of molten metal. For example, graphite can maintain structural integrity under continuous heating due to its high thermal stability; special alloys improve corrosion resistance by adding chromium elements, which increases the service life of the ladle by more than 30%.

Insulation

The thermal insulation performance is mainly achieved through the ladle lining. And the 20-40cm thick high-aluminum refractory layer can slow down heat loss. This design controls the temperature fluctuation of the melt transfer process within ±15℃. Ensuring that the metal fluidity during pouring meets the process requirements.

Actual measurements show that the moisture content of the optimized castable is less than 3%. And its thermal conductivity is only 0.08-0.12W/(cm·K), which significantly reduces energy consumption. Maintaining temperature stability is crucial for casting molding. When heat loss exceeds 5%, it may cause cold shut or porosity defects.

Pour spout design

The inclined nozzle can achieve precise flow control, reduce molten metal splashing. And ensure that the molten metal is smoothly injected into the injection chamber.

Ease of use

The handle adopts ergonomic design to reduce operator fatigue. It is compatible with the robot arm interface to improve the operation safety in high temperature environment.

Temperature resistance

The ladle body and lining are made of special refractory materials. Which can withstand the high temperature of molten metal for a long time (usually >1000℃). Avoid deformation or failure, and ensure the safety and stability of the casting process.

Application in HAICHEN’s Die-Casting Solutions

As a manufacturer that provides integrated die-casting systems, HAICHEN designs its ladles to meet these critical requirements precisely.

For instance, HAICHEN ladles often feature a optimized scraping edge and advanced ceramic lining, which not only maintain molten metal temperature effectively but also minimize oxidation and iron contamination during transfer.

This design supports the production of high-integrity castings, such as thin-walled automotive components, by significantly reducing gas entrapment.

Furthermore, their standardized interface allows for effortless integration into HAICHEN’s automated pouring units, ensuring the ±2% pouring accuracy and consistent cycle times demanded by modern, high-volume production lines.

Application scenario: Differentiated requirements for cold chamber vs. hot chamber die casting

| Die casting type | Core requirements for ladles | Adaptation solutions |

| Cold chamber die casting | Large capacity (≥5kg) + fast transfer Steel | ladles + robotic arm collaboration, suitable for aluminum/magnesium alloys |

| Hot chamber die casting | Small capacity + low temperature corrosion resistance | Ceramic lined ladles, suitable for zinc/tin alloys (melting point ≤450℃) |

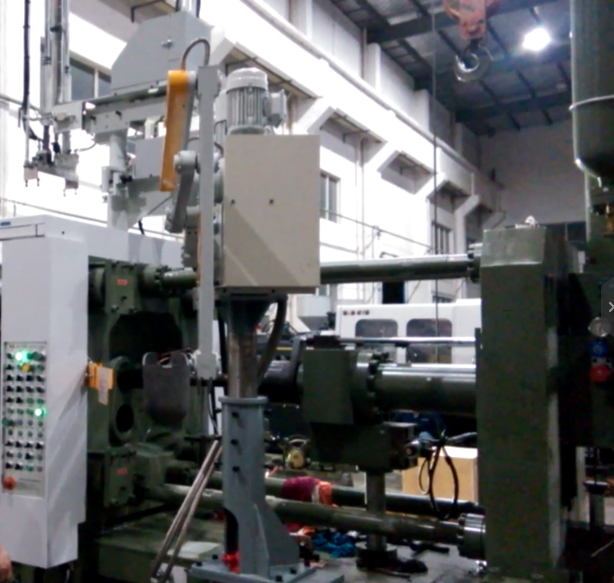

Haichen Machinery-features of die casting ladle

Precise control

Haichen die casting ladle are equipped with precision gate design. When operating, you will feel the process of molten metal flowing smoothly into the shot barrel. This design can effectively reduce metal splashing and reduce the oxidation problem caused by the contact between molten metal and air. Making the production environment safer and cleaner.

High-quality materials

We use high-grade heat-resistant materials to manufacture ladles. You will clearly feel its stability under extreme temperatures in daily use. This material property directly extends the life of the equipment, reduces the frequency of repairs caused by high-temperature deformation, and saves you long-term maintenance costs.

Engineers rely on die casting spoons to handle molten metal more safely and accurately control the amount of each pour. Which not only reduces scrap rates but also significantly improves part dimensional accuracy. It is this control of process details that makes die casting spoons an indispensable tool in the production of precision metal parts.