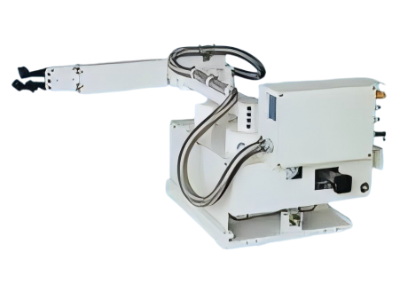

The function of the extractor is to eject the solidified casting from the mold.

As a key equipment for die-casting automated production, the extractor (also known as the extractor manipulator) plays an irreplaceable role in improving efficiency, ensuring safety and optimizing processes.

The die-casting extractor protects the life of the mold through automated operation and reduces wear and tear that may be caused by manual intervention. It can stably grasp the castings to prevent the products from falling or deforming, and ensure the consistent quality of the castings each time they are demolded.

The following combines technical principles, industry applications and system synergy to fully analyze its functional system.

Core Function Definition and Positioning

The extractor is a supporting automation equipment for the die-casting machine. It is mainly used to complete three key tasks after the mold is opened: automatically grab the casting, separate the gate waste, and transport the processed workpiece to the next process.

Its core functions are reflected in three aspects:

- Process connection: replace manual extraction in a high-temperature environment, ensure the continuous operation between die-casting and post-processing processes, and ensure the safety of operators.

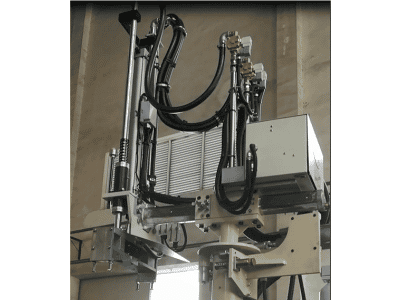

- System coordination: It can linked with the die-casting machine, spraying equipment. And conveyor belt to build a complete automated production line and reduce manual intervention.

- Precision control: The configured six-axis robot can achieve a repeatable positioning accuracy of ±0.1mm, effectively avoiding errors that may caused by manual operation.

Function of the extractor from the die casting machine

- Part Ejection

- Mold Protection

- Consistent Quality

- Operator Safety

- Cushioning and Shock Absorption

Part Ejection

The main task of the extractor is to remove the cooled molded casting from the mold cavity. This step is fully automatic and is critical for large-scale and fast production. With it, the entire production line can be automated.

Mold Protection

After using the extractor instead of manual operation, workers do not need to directly contact the high-temperature mold, which can prevent the mold from being damaged or deformed. Automatic ejection not only extends the life of the mold, but also ensures the accuracy of the product size.

Consistent Quality

The extractor can stably remove the casting from the mold. This consistent and uniform extraction action ensures that the quality of each batch of products remains stable. In large-scale production, this stability is crucial because any slight fluctuation can cause defects in the product.

Operator Safety

The extractor automates the ejection process of the casting. This means that the operator no longer needs to directly touch the casting that has just come out of the mold and is still hot, nor does he need to frequently operate heavy molds. This greatly reduces the risk of worker injury and significantly improves workplace safety.

Cushioning and Shock Absorption

Some ejection devices designed with a buffer protection function. Engineers have specially designed this structure (such as ACE’s MA/ML series buffer) to make the ejection process smooth and controllable, effectively reducing the impact force on the casting and mold.

This protection mechanism has two practical benefits: it can prevent accidental damage to the product during demolding. And extend the service life of the mold – feedback from experienced workers in the injection molding workshop shows that molds using this type of buffer device can used for an average of 2-3 more production cycles.

Differences in industry application scenarios and requirements

In the application scenarios of different industries, the functional design of the extractor needs to meet the differentiated process requirements.

- Automotive integrated die-casting field: For 2,000-ton large-scale die-casting machines. The extractor needs to have a load capacity of more than 10 kg. And an ultra-long arm span design to meet the gripping needs of body structural parts.

- Consumer electronics manufacturing field: When processing precision parts such as mobile phone frames. The extractor must be equip with anti-scratch fixtures and accurately control the gripping force to avoid surface damage to the parts.

- Industrial equipment production field: The extractor design needs to be compatible with the multi-hole water outlet separation process of pump and valve castings. And integrate an automatic deburring module to improve post-processing efficiency.

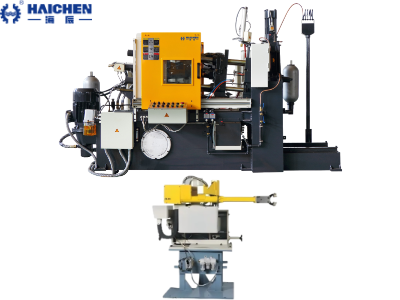

Advantages of Haichen die casting machine extractor

- High-efficiency design

- Durability

- Easy operation

- HAICHEN Real-World Application Case

High-efficiency design

Haichen’s extractor adopts high-efficiency design to ensure fast and reliable ejection of castings, reducing downtime in production.

Durability

Made of wear-resistant materials, Haichen’s extractor has excellent durability and can work stably. And permanently under high pressure and high temperature environments.

Easy operation

The design focuses on user experience, making operation simple and intuitive, reducing the training cost and difficulty of operators.

HAICHEN Real-World Application Case

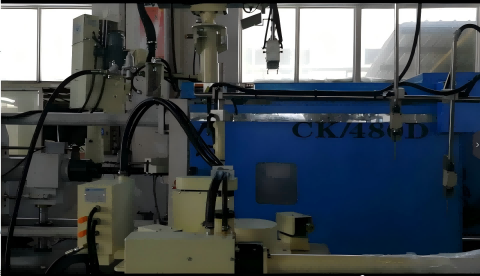

In automated die-casting units, the stable operation of the part removal system is crucial for production cycle time. A customer uses a HAICHEN die-casting machine to produce motor housings for new energy vehicles. The castings have a complex structure and require a precise removal process. HAICHEN integrated a customized part removal system for this customer, optimizing the gripper design and removal trajectory to achieve fast and damage-free part removal. This solution reduced the production cycle time by approximately 15% and lowered the rate of casting surface damage caused by improper removal to below 0.5%, ensuring the efficiency and stability of the production line.

With continuous technological upgrades, the pick-up function of Haichen die-casting machines has been continuously strengthened, significantly simplifying the production process. This not only improves the quality stability of die-castings, but also accurately meets the strict standards of various industries.

With these features, the equipment creates a safe and reliable production environment for customers. Effectively helping enterprises promote intelligent manufacturing and automation transformation.