Future development trends of platen in die casting:

- Integration with Mega-Casting (Gigacast) Technology

- Adoption of Smart Platens with Embedded Sensors

- Advancements in Materials and Coatings

- Enhanced Thermal Management Integration

- Focus on Sustainability and Energy Efficiency

The platen, a critical component in die casting machines that provides the foundation for mold mounting and withstands immense clamping forces, is undergoing significant transformation.

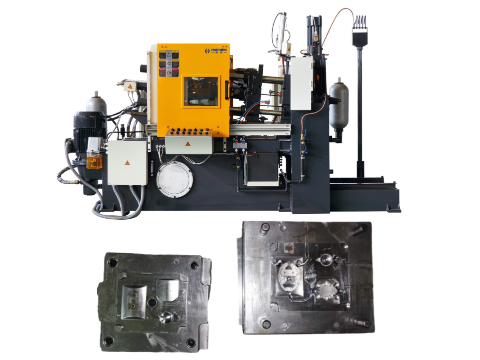

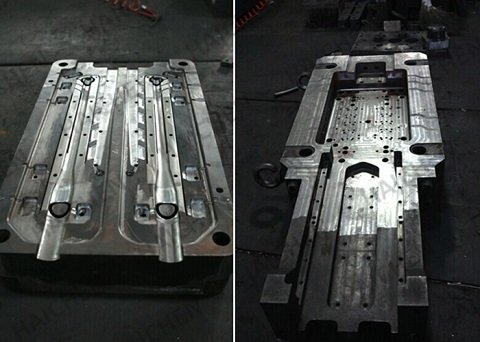

Haichen has been processing die-castings for nearly two decades.

We have rich experience in processing die-casting templates, tie rods, bushings, split tie rod nuts and other products.

The weight of die-casting templates can easily exceed 40,000 pounds, so we are able to handle and process such heavy parts, which gives us a significant advantage.

The future of die-casting machine formwork is centered on two-plate intelligence, high-performance materials.

And green production, supporting large-scale integrated die-casting technology innovation.

While breaking through the technical barriers and cost challenges brought about by large-scale.

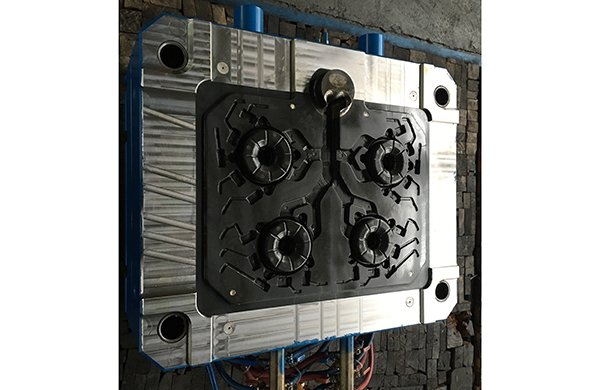

The structure and composition of die-casting machine platen

The die casting machine template is the core component of the die casting mold, usually including the moving mold, fixed mold, push rod, guide post, guide sleeve, core and other structures.

For instance, Haichen‘s template structure consists of components such as the moving mold seat plate, push rod, guide column, and core, which together form the template structure of the die-casting mold.

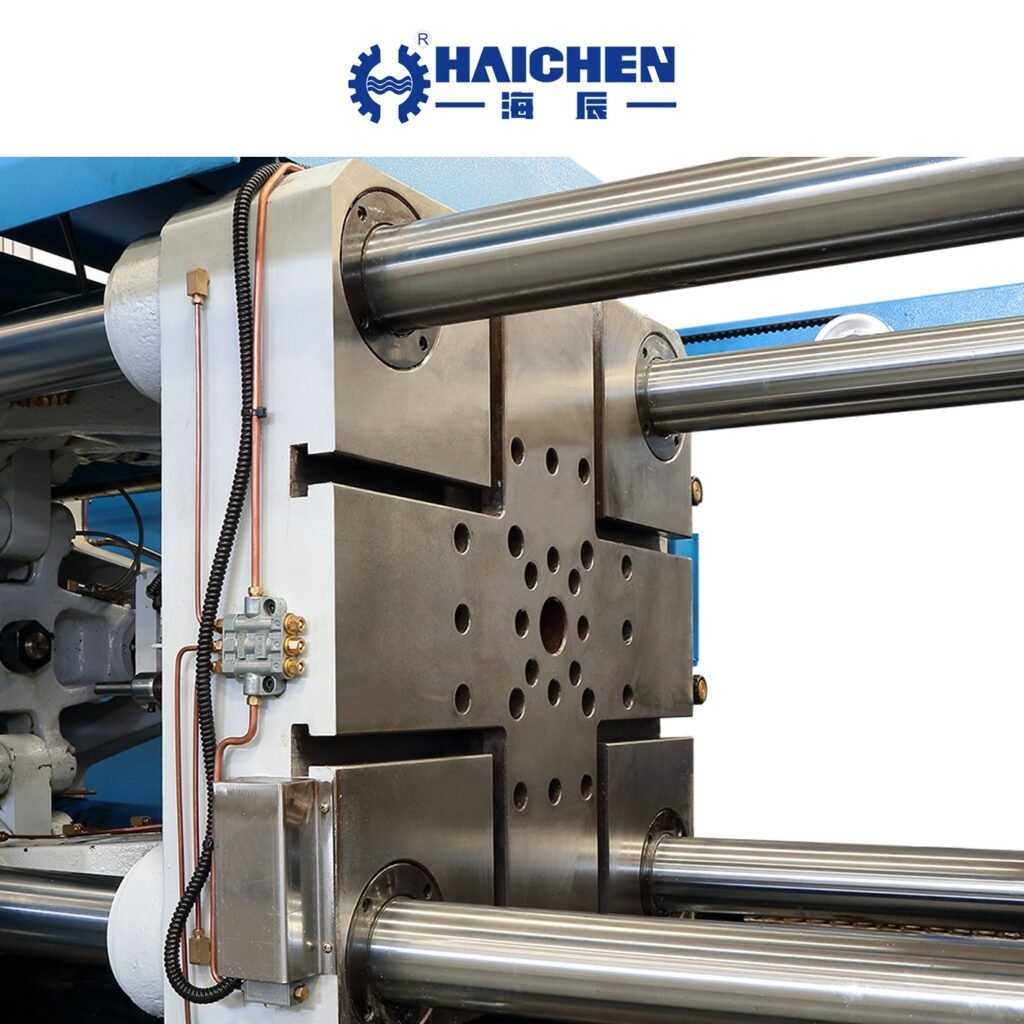

Die-casting machine templates are usually made of cast iron or cast steel, and some high-end equipment uses forged steel.

The manufacturing of formwork must meet the requirements of high hardness and wear resistance.

For instance, national standards such as GB/T4678.1-2017 have clear regulations on the materials and hardness of formwork.

Integration with Mega-Casting (Gigacast) Technology

- Increased Size and Structural Reinforcement

- Modular and Flexible Designs

Increased Size and Structural Reinforcement

To accommodate the production of large-scale, integrated components like electric vehicle (EV) battery housings and entire automotive chassis segments, platens are evolving to be larger and more robust.

This necessitates designs that can withstand significantly higher clamping forces while minimizing deflection to maintain part precision.

Advanced finite element analysis (FEA) is crucial for optimizing the structural integrity and weight of these massive platens.

Modular and Flexible Designs

Some systems might incorporate modular platen designs or flexible mounting solutions to adapt to different large-scale mold sets efficiently, supporting the trend towards high-mix, large-part production.

Adoption of Smart Platens with Embedded Sensors

- Real-time Monitoring and Data Acquisition

- Integration with AI and Predictive Maintenance

Real-time Monitoring and Data Acquisition

Future platens will likely be “smart,” integrated with IoT (Internet of Things) sensors to monitor critical parameters in real-time.

Temperature Sensors

Mapping thermal distribution across the platen to detect hotspots and ensure thermal stability, crucial for consistent part quality and mold life.

Stress and Strain Gauges

Monitoring mechanical stress and deflection during injection and clamping cycles.

This data is vital for predictive maintenance, preventing catastrophic failures, and optimizing process parameters.

Vibration Sensors:Detecting imbalances or issues in the clamping mechanism.

Integration with AI and Predictive Maintenance

The data collected from these sensors will feed into AI-driven analytics platforms.

Predictive Maintenance

Forecasting platen and mold component fatigue, scheduling maintenance before failures occur, and minimizing unplanned downtime.

Process Optimization

AI algorithms can analyze data to recommend adjustments for optimal clamping force, reducing cycle times and energy consumption.

Advancements in Materials and Coatings

- High-Strength and Fatigue-Resistant Alloys

- Advanced Coatings for Durability and Performance

High-Strength and Fatigue-Resistant Alloys

To endure the extreme stresses of mega-casting and high-cycle operations.

There will be a greater adoption of high-performance steel alloys and possibly composite materials.

These materials offer superior tensile strength, fatigue resistance, and toughness, extending the platen’s service life significantly.

Advanced Coatings for Durability and Performance

New surface treatments and coatings will be applied to platen surfaces especially those contacting the mold to enhance properties like:

Wear Resistance: Reducing damage from mold mounting and demounting.

Corrosion Resistance: Protecting against coolant leaks and environmental factors.

Non-Stick Properties: Facilitating the cleaning of any spilled release agents or debris.

Enhanced Thermal Management Integration

- Optimized Cooling Channels

- Active Temperature Control Systems

Optimized Cooling Channels

While cooling is primarily a mold function, large platens in thermal equilibrium with massive molds can benefit from built-in conformal cooling channels to help manage overall system temperature.

This is closely linked to mold temperature control, a critical factor highlighted in the search results for improving product quality and cycle times.

Active Temperature Control Systems

For applications requiring extreme thermal stability, platens might incorporate active heating or cooling systems to maintain a precise temperature profile, further reducing thermal stresses and improving casting consistency.

Focus on Sustainability and Energy Efficiency

- Lightweighting through Design Optimization

- Compatibility with Eco-friendly Processes

Lightweighting through Design Optimization

Using topology optimization in design software, platens can be manufactured to be lighter without compromising strength.

This reduces the inertial mass the machine must move, leading to lower energy consumption per cycle.

Compatibility with Eco-friendly Processes

As the die casting industry moves towards greater sustainability, platen design and operation will align with efforts to reduce the overall carbon footprint.

Such as enabling faster cycle times and supporting the use of recycled aluminum alloys.

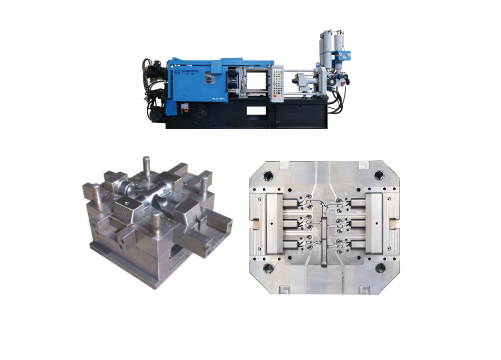

Haichen Machinery

The die casting industry is undergoing a remarkable transformation driven by advancements in materials, techniques, and sustainability practices.

These emerging trends are shaping the future of die casting, offering opportunities for enhanced performance, efficiency, and environmental stewardship.

Our team of experts is here to help you navigate the future of die casting and leverage these innovations for your success.