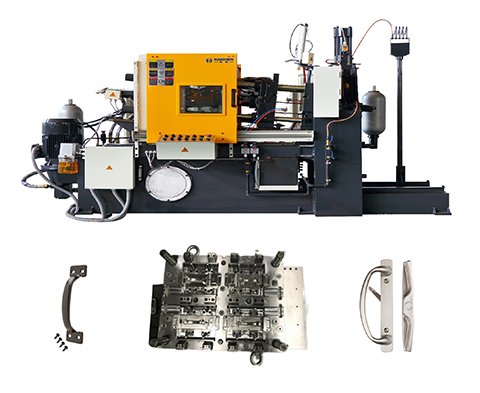

Haichen zinc alloy door handle die-casting machine is a kind of special equipment for producing zinc alloy door handle.

We offer various die-casting solutions for indoor and outdoor metal door handle production.

This equipment is capable of injecting molten zinc alloy into the mould through high pressure to form the desired shape of the door handle.

It is usually produced using the hot chamber die casting process.

And after subsequent surface treatment and processing, such as electroplating, sandblasting, etc..

In this way, it can improve the durability and aesthetics of zinc alloy door handles.

Advantages of zinc alloy door handle die-casting machine

Zinc alloy die casting machine has strong performance and extremely high capacity.

With five advantages:

- High precision of zinc alloy door handle products

- High-volume production

- Die casting machine production economy

- Zinc alloy door handle die casting plasticity

- Zinc alloy die casting environmental protection

Zinc alloy door handle products high precision

Zinc alloy die casting can produce high precision parts with smooth and delicate surface.

Suitable for application scenarios that require high precision.

Mass production capacity

Die casting machine high efficiency, a machine within eight hours can complete a large number of die casting tasks, suitable for mass production.

Economy

Zinc alloy material cost is low.die casting size is accurate and surface finish.

Reduces the need for subsequent processing, thus reducing production costs.

Zinc alloy door handle die casting plasticity

As we all know Zinc alloy material fluidity is good, can die casting complex shape and thin wall structure parts.

Zinc alloy die casting environmental protection

Zinc alloy die casting surface treatment is simple, is an environmentally friendly material.

Production steps of zinc alloy door handle die-casting machine

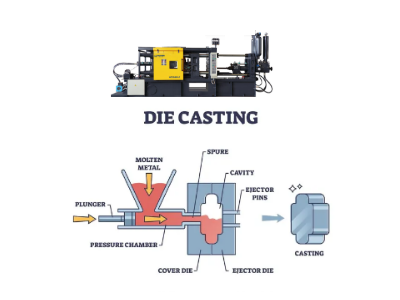

The production steps of the door handle die casting machine are similar to conventional hot chamber die casting products.

It needs to be carried out according to the details of the door handle product.

It mainly includes six zinc alloy door handle die casting key links:

- Zinc alloy door handle die casting mould preparation

- Zinc alloy melting

- Zinc alloy door handle die casting moulding

- Cooling and curing

- Open the mould to take out the zinc alloy door handle

- Zinc alloy door handle subsequent processing

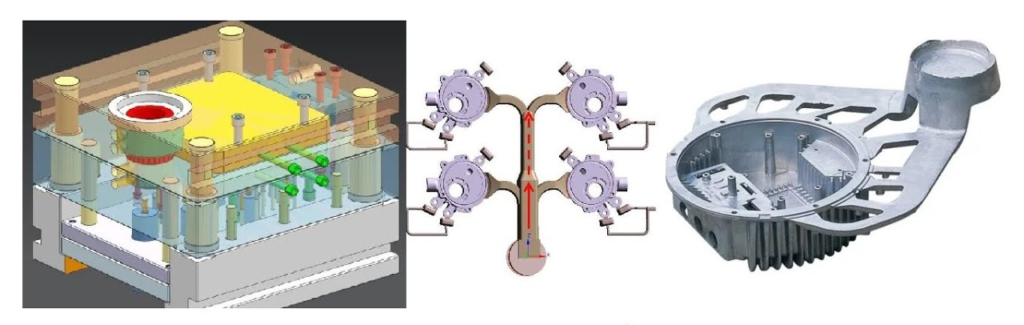

Zinc alloy door handle die casting mould preparation

First need to prepare steel zinc alloy door handle die casting mould.

According to the zinc alloy door handle die casting products to customise.

Zinc alloy melting

Put the zinc alloy into the furnace and heat it to the melting point to make it liquid.

Die casting moulding

The melted zinc alloy is pressed and injected into the mould cavity through a hot chamber machine gooseneck pot.

High pressure is used to fill the mould quickly and form the desired shape.

Cooling and curing

Inside the mould, the zinc alloy liquid gradually cools and solidifies into the zinc alloy door handle shape.

Open the mould and remove

When the alloy is fully solidified, the mould is opened and the zinc alloy door handle is removed.

Subsequent processing

After removal, the zinc alloy door handle may require further processing and treatment, such as removal of surface defects, polishing, etc., to meet specific application requirements.

These steps demonstrate the complete production process of a door handle die casting machine from raw material to finished product.

Technical Advantages of Haichen Zinc Door Handle die casting machine

Haichen hot chamber die casting machine is technically mature and cost-effective.

With the following technical advantages:

- Haichen die-casting machine with high precision and stability.

- Haichen die-casting machine intelligent and modular design.

- Haichen die casting machine high efficiency production and low energy consumption.

- Environmental protection and energy saving

- Haichen hot chamber Handle die casting machine multifunctional and widely used

- Long Life & High Durability

Haichen die-casting machine with high precision and stability

Haichen Zinc Door Handle die casting machine adopts advanced hydraulic control system and temperature regulation technology.

Ensure die-casting accuracy and equipment stability, suitable for manufacturing complex shapes and precision size of Zinc Door Handle.

Haichen die-casting machine intelligent and modular design

Haichen Zinc Door Handle die casting machine machine focus on intelligent and modular design.

Integrated intelligent control module, support remote monitoring and data analysis, improve production management and quality control efficiency.

Haichen die casting machine high efficiency production and low energy consumption

Haichen die casting machine has multi-stage pressure and speed control function.

It can achieve fast and efficient production, while optimising energy consumption and reducing production costs.

Environmental protection and energy saving

Haichen Zinc Door Handle die casting machine design meets the requirements of environmental protection.

Adopt energy-saving technology to reduce energy consumption in the production process.

Haichen hot chamber Handle die casting machine multifunctional and widely used

Suitable for a wide range of industrial applications, such as automotive parts, home appliance housings and precision machinery parts, to meet the needs of different industries.

Long Life & High Durability

Haichen Zinc Door Handle die casting machine is designed for durability and long service life to withstand high intensity production demands.

These technical advantages make Haichen Zinc die casting machine competitive in the market and able to meet high quality and high efficiency production needs.

Welcome to contact us for details, we will build the right Zinc Door Handle die casting line for you.