The Human-Machine Interface (HMI) and Programmable Logic Controller (PLC) in die casting work together to help automate, watch over, and better the making process. The joined efforts of these advanced tools offer us the tech help and future chances for exact control of the die casting method.

Now let’s check them out.

Various types of automation control in die casting process

- HMI (Human-Machine Interface)

- PLC (Programmable Logic Controller)

- Integration of HMI and PLC

- Critical Applications in Die Casting

- Safety and Redundancy

- Advanced Trends

- Example Workflow

HMI (Human-Machine Interface)

- Function:

- Provides a user-friendly interface for operators to interact with the die casting machine.

- Displays real-time data (e.g., temperature, pressure, cycle time, machine status).

- Allows input of process parameters (e.g., injection speed, clamping force).

- Visualizes alarms and diagnostics for troubleshooting.

- Features in Die Casting:

- Touchscreen panels for adjusting settings like melt temperature or shot profile.

- Graphical representation of the casting cycle (e.g., mold closure, metal injection, cooling, ejection).

- Historical data logging for quality control and traceability.

PLC (Programmable Logic Controller)

- Function:

- Executes control logic to automate the die casting sequence.

- Processes inputs from sensors (e.g., thermocouples, pressure transducers, position sensors).

- Outputs commands to actuators (e.g., hydraulic valves, servo motors, heaters).

- Key Tasks in Die Casting:

- Cycle Control: Manages sequential steps: mold clamping, molten metal injection, cooling, and part ejection.

- Pressure Regulation: Adjusts hydraulic or servo-driven injection pressure for consistent fill.

- Temperature Management: Controls die heaters and cooling systems to maintain optimal temperatures.

- Safety Interlocks: Ensures machine stops if safety doors are open or sensors detect faults.

Integration of HMI and PLC

- Communication Protocols:

- Industrial Ethernet (Ethernet/IP, Profinet): Enables fast, real-time data exchange.

- Modbus/Profibus: Legacy protocols for connecting HMI and PLC in older systems.

- Workflow:

- Operators input parameters (e.g., injection speed) via the HMI.

- The PLC receives these settings and adjusts machine operations accordingly.

- Sensors feed real-time data (e.g., melt temperature) back to the PLC.

- The PLC updates the HMI display, providing operators with live feedback.

Critical Applications in Die Casting

- Injection Control:

- The PLC ensures precise control of the shot sleeve and plunger movement.

- HMI displays injection pressure curves for quality assurance.

- Die Temperature Management:

- PLC regulates die heaters and cooling channels.

- HMI shows thermal profiles to prevent premature solidification or warping.

- Fault Detection:

- PLC triggers alarms (e.g., “low lubricant pressure”) and halts the machine if needed.

- HMI highlights faults with visual/audible alerts and suggests corrective actions.

Safety and Redundancy

- Emergency Stop (E-Stop):

- HMI includes physical E-Stop buttons; PLC enforces safety shutdowns.

- Redundant Systems:

- Dual PLCs or backup HMIs ensure continuity in high-volume production.

Advanced Trends

- Industry 4.0 Integration:

- PLCs and HMIs connect to IoT platforms for predictive maintenance (e.g., monitoring plunger wear).

- Data analytics optimize cycle times and reduce scrap rates.

- SCADA Systems:

- HMIs feed data to Supervisory Control and Data Acquisition (SCADA) systems for plant-wide monitoring.

Example Workflow

- Setup: Operator selects a “Aluminum Engine Block” recipe via HMI.

- Execution:

- PLC closes the die, injects molten aluminum at 100 MPa, and activates cooling.

- HMI shows real-time pressure/temperature graphs.

- Completion: PLC ejects the part; HMI logs cycle time and alerts for mold lubrication.

Die casting machine PLC workflow

The Programmable Logic Controller (PLC) orchestrates critical automation stages in die casting. Below is an evidence-based breakdown of its workflow:

- Parameter Setup & Initialization

- Mold Clamping & Locking

- Molten Metal Injection

- Pressure Holding & Cooling

- Mold Opening & Ejection

- Part Handling & Post-Processing

- Real-Time Monitoring & Fault Management

Parameter Setup & Initialization

- Process Parameter Configuration: Operators input key parameters (e.g., injection speed, clamping force, cooling time, temperature) via HMI (Human-Machine Interface). Advanced systems support password protection and multi-program storage for different molds.

- System Self-Test: During startup, the PLC checks hydraulic systems, sensors, motors, and safety circuits to ensure operational readiness.

Mold Clamping & Locking

- Clamping Force Control: Hydraulic systems drive a five-point toggle clamp or C-frame structure to ensure uniform mold closure.

- Safety Checks: The PLC verifies mold alignment, temperature, and safety door status before clamping to prevent accidents (e.g., molten metal splatter).

Molten Metal Injection

- Automatic Ladling: A robotic arm or automated ladle transfers molten metal (e.g., aluminum, zinc) into the cold chamber (for high-melting-point alloys) or hot chamber (for low-melting-point alloys).

- Injection Phase Control:

- Slow Shot Phase: The PLC initiates slow-speed injection to fill the mold cavity while minimizing air entrapment.

- High-Speed Intensification: A servo-controlled valve switches to high-pressure injection, ensuring complete mold filling. Closed-loop control (e.g., Allen Bradley PLCs) monitors pressure and velocity in real time.

Pressure Holding & Cooling

- Pressure Maintenance: The PLC maintains high pressure during solidification to eliminate shrinkage defects. Proportional valves adjust pressure levels dynamically.

- Mold Cooling: Water-based or oil-based cooling systems activate, with spray timing and duration controlled by the PLC. Some systems allow zone-specific cooling adjustments.

Mold Opening & Ejection

- Mold Release: Hydraulic actuators retract the moving mold plate after preset cooling time or temperature thresholds are met.

- Ejection Mechanism: Ejector pins or robotic arms remove the casting. The PLC synchronizes ejection speed and stroke to avoid part deformation.

Part Handling & Post-Processing

- Automated Removal: Robotic arms transfer castings to trimming stations or conveyors. Vision systems may inspect parts for defects in integrated workflows.

- Mold Reset: Spray systems clean and lubricate molds for the next cycle. The PLC logs production counts and updates shift data.

Real-Time Monitoring & Fault Management

- HMI Visualization: Dashboards display production metrics (e.g., cycle time, defect rate), system status, and error codes. Remote access via industrial networks (e.g., Ethernet/IP) is common.

- Adaptive Control: Advanced PLCs use fuzzy-PID algorithms to compensate for process variations (e.g., temperature fluctuations), improving precision.

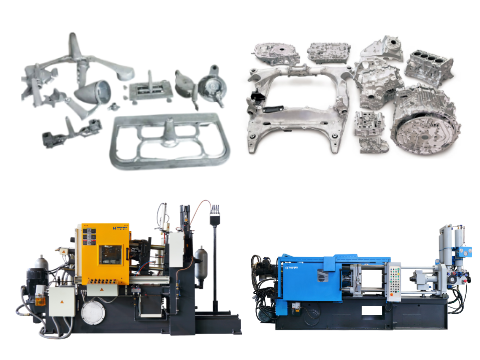

PLC Variations by Die Casting Machine Type

- Cold Chamber Machines: Optimized for aluminum/copper alloys. PLCs manage complex metal transfer and hydraulic coordination.

- Hot Chamber Machines: Designed for zinc/magnesium alloys. PLCs integrate furnace and injection controls for seamless operation.

Advanced Integration & Compliance

- Automation Cells: PLCs synchronize with peripheral equipment (e.g., sprayers, trimmers) for end-to-end production lines.

- Energy Efficiency: Servo-driven systems and smart PLCs reduce energy consumption by up to 40%, often complying with ISO 14001 and CE standards.

The PLC serves as the central brain of die casting machines, enabling precision, safety, and repeatability across metal injection, solidification, and part extraction. Its adaptability to different alloys and mold designs makes it indispensable in modern foundries. Key advancements include IoT connectivity for predictive maintenance and AI-driven process optimization.

High-precision Siemens PLC for Haichen die-casting machine

Haichen die casting machines utilize high-precision Siemens PLC control systems in select models. Below are the technical details:

- Siemens PLC in C-Series Cold Chamber Machines

The C-Series cold chamber machines integrate Siemens PLCs, supporting multilingual interfaces and mold parameter storage. Real-time adjustments for four-stage injection positions (controlled via magnetic strip scales) and ±1 bar boost pressure repeat accuracy enhance part surface finish and dimensional consistency, ideal for high-demand products. - PLC-Powered Injection System Coordination

The Siemens PLC directly controls the four-stage injection process (slow-to-fast switching), synchronized with magnetic strip position detection and pressure sensors. This ensures rapid, stable injection cycles with high repeatability, surpassing traditional manual controls in power precision. - Key High-Precision Features

- Analog Signal Processing: Siemens PLCs use high-resolution analog-to-digital conversion modules to precisely monitor temperature and pressure (e.g., molten alloy temperature control).

- Motion Control: Fast PLC scan cycles and closed-loop control enable precise adjustments of injection speed and clamping force. For example, Haichen’s HM-Series optimizes shot systems for “fast, accurate, and stable” injection.

Haichen integrates Siemens PLCs into critical models (e.g., C-Series) to deliver exceptional stability and repeatability, meeting stringent requirements for complex die casting processes through optimized hydraulic and injection systems.The integration of HMI and PLC in die casting ensures precision, efficiency, and safety. While the PLC handles automation and real-time control, the HMI empowers operators with intuitive oversight and adjustments. Together, they enable high-quality production with minimal downtime, aligning with modern smart manufacturing trends.

Contact Haichen for more die casting control system details.