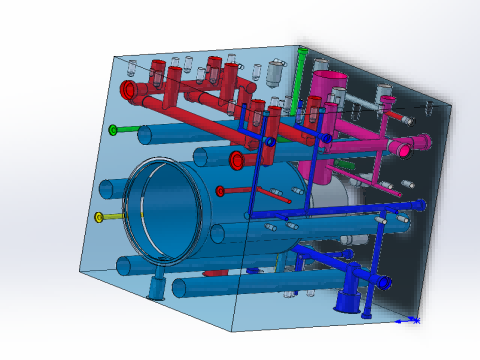

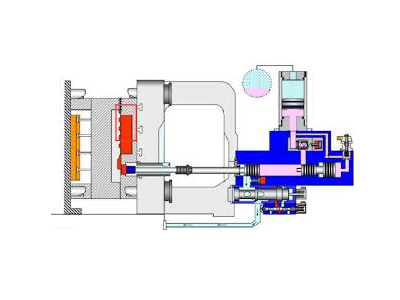

The working principle of booster cylinder involves using hydraulic pressure to amplify force for effective molten metal injection.

Die casting machines rely on numerous supporting elements for precise and effective operation, and the boosting cylinder ranks among the most critical of these components because it enhances machine-wide performance.

Its primary assignment is to deliver the high pressures necessary for the molten alloy to fill the cavity without delay and without the risk of voids.

Recognizing the boosting cylinder’s mechanism is therefore indispensable to fine-tuning the process, yielding consistently dense and accurately defined castings.

The following sections will delineate the cylinder’s internal cycle, operating pressures, and overall contribution to die casting efficiency and accuracy.

Definition and Core Functions of a Booster Cylinder

A booster cylinder is the core boosting device in a die-casting machine. It amplifies low-pressure air dozens of times through gas-to-liquid conversion, producing ultra-high hydraulic pressure. Its core value lies in:

- Pressure Amplification: Using pure compressed air (typically 0.5-0.7 MPa) as a power source, it leverages piston area differential to multiply pressure (up to 10-40 times the input pressure), delivering high-pressure oil to drive the actuator.

- System Simplification: Replacing traditional hydraulic pump stations, it reduces piping complexity, energy consumption, and maintenance costs.

- Precise Control: It supports stepless adjustment of pressure and stroke, adapting to the diverse mold and casting process requirements.

Function of Boosting Cylinders

- Increase Injection Pressure: Boosting cylinders are designed to increase the injection pressure of the molten metal. This is essential for ensuring that the metal fills the mold completely and quickly, resulting in a high-quality casting with minimal defects.

- Maintain Consistency: By providing a consistent force, boosting cylinders help maintain the stability of the casting process. This consistency is vital for producing castings with uniform dimensions and properties.

Working Principle

- Hydraulic System: Boosting cylinders typically operate within a hydraulic system. The hydraulic fluid is pressurized and directed to the cylinder, which then exerts force on the plunger or piston.

- Force Multiplication: The hydraulic system allows for force multiplication, enabling the boosting cylinder to generate a much higher force than the input pressure. This amplified force is what drives the molten metal into the mold with the required pressure.

- Control and Precision: Valves and pressure sensors within the hydraulic system control the operation of the boosting cylinder. These components ensure precise force application and allow adjustments according to the specific requirements of the casting process.

Importance in Die Casting

- Enhanced Quality: The use of boosting cylinders results in castings with better surface finish. And fewer defects such as porosity and shrinkage.

- Increased Efficiency: By ensuring complete and rapid filling of the mold. Boosting cylinders improve the overall efficiency of the die casting process, reducing cycle times and increasing production rates.

HAICHEN die casting machine manufacturer introduction

HAICHEN stands out as a foremost designer and supplier of die casting equipment, widely respected for innovative design, robust construction, and dependable performance.

The product portfolio embraces machines of varying tonnage, all of which are fitted as standard with state-of-the-art boosting cylinders to guarantee operational stability and the tightest tolerances throughout the production life cycle.

Steadfast adherence to quality milestones and a philosophy of Kaizen ensure that HAICHEN equipment is adaptable, durability is built in, and operational costs remain low—advising manufacturers that their investment will continue to expand process reliability.

The breadth of HAICHEN’s die-casting technology expertise confirms them as the partner of choice for enterprises intent on reinforcing production throughput and elevating product quality.

The working principle of boosting cylinder in die casting machines are essential components that enhance the casting process.

By leveraging hydraulic systems to amplify injection pressure, they ensure that molten metal fills the mold accurately and efficiently. This results in high-quality castings with minimal defects.