Checking the quality of aluminum castings is a complex process involving multiple steps and methods.

Steps to Check the quality of aluminum castings

Appearance inspection

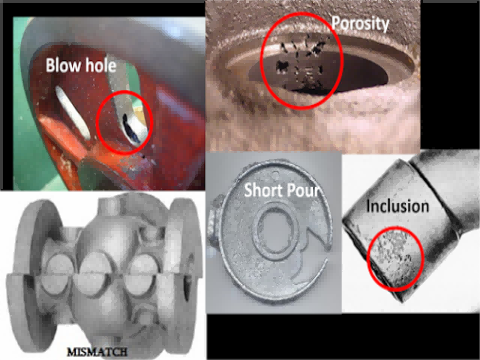

- Naked-eye observation and touching: Firstly, we observe the surface of the casting by naked eye to check whether there are any defects such as cracks, air holes, shrinkage holes, and so on.

- Surface Quality Inspection: Use image inspection technology (e.g. X-ray inspection) to identify subtle surface defects and ensure that the surface of the casting is smooth and flawless.

Non-destructive testing of checking the quality of aluminum castings

- X-ray Inspection: X-ray inspection is a commonly used NDT method that can clearly show defects inside the casting, such as porosity, shrinkage and inclusions.

- Ultrasonic inspection: Ultrasonic inspection is also an effective NDT method to detect defects inside the casting.

- Magnetic particle inspection: It is suitable for detecting defects on the surface and near surface of castings.

Chemical composition analysis of checking the quality of aluminum castings

- Spectral Analysis: Analyze the chemical composition of aluminum alloys by spectrometer to ensure that it meets the design requirements.

- Conventional Elemental Analysis: Use direct reading spectrometer to quickly and accurately grasp the compositional state of the alloy.

Microstructure characterization

- Metallographic analysis: Observe the microstructure of the casting through metallographic microscope and analyze its grain size, organization and morphology.

- Thermal analysis: study the solidification behavior and microstructure of the alloy through thermal analysis methods (such as differential scanning calorimetry).

Mechanical properties testing

- Tensile test: Measure the mechanical properties of castings such as tensile strength, yield strength and elongation using a universal testing machine.

- Hardness test: Measure the hardness of castings by hardness tester to evaluate their wear resistance and impact resistance.

Dimensional accuracy and geometry checking

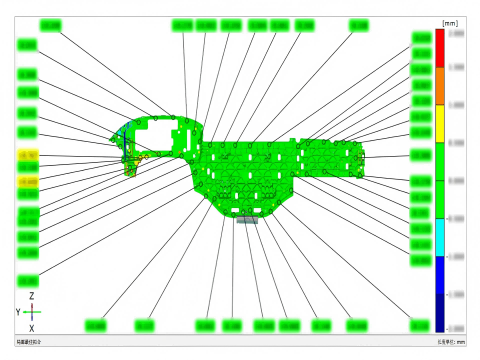

- Coordinate Measuring Machine (CMM) : The dimensional accuracy and geometry of the casting is measured using a CMM to ensure that it meets the design requirements.

- Optical Scanner: The surface quality and overall shape of the casting is checked by means of an optical scanner.

Internal quality control of checking the quality of aluminum castings

- Porosity and Shrinkage Inspection: Evaluate the porosity and shrinkage of castings through radiographic inspection and microscopic observation.

- Defect classification: Classify defects according to their type and severity and develop appropriate improvement measures.

Post-treatment quality control

- Heat Treatment: Heat treat the castings to improve their mechanical properties according to the application requirements.

- Surface Coating: Surface coating is applied to castings that require plating or painting to improve their corrosion resistance and aesthetics.

Quality Management System

- Continuous monitoring: Continuous monitoring of the production process through quality management tools (e.g. 5W2H, Ishikawa diagram, ABC-D wallowing Z method) ensures the consistency of casting quality.

- Periodic Inspection: Regular quality inspection of castings to ensure that they meet the standard requirements.

By combining these methods, you can comprehensively assess the quality of an aluminum casting and ensure it meets the required standards for its intended application.

Haichen aluminium die casting machine

Haichen is a well-known manufacturer of aluminum die casting machines and related equipment, specializing in high-pressure die casting (HPDC) solutions.Our cold chamber and hot chamber die casting machines are widely used in industries such as automotive, electronics, and consumer goods for producing high-quality aluminum castings with precision and efficiency.

If you are considering purchasing or using aluminum die casting machine, welcome to consult us.