To ensure the quality of an aluminium die casting, a comprehensive approach involving multiple inspection techniques and adherence to industry standards is essential.

The quality control process for aluminum die castings begins with raw material inspection. Aluminum alloys undergo comprehensive testing to ensure they meet specific standards for chemical composition, strength, heat resistance, and durability. This proactive approach minimizes the risk of producing parts that fail to meet product performance requirements.

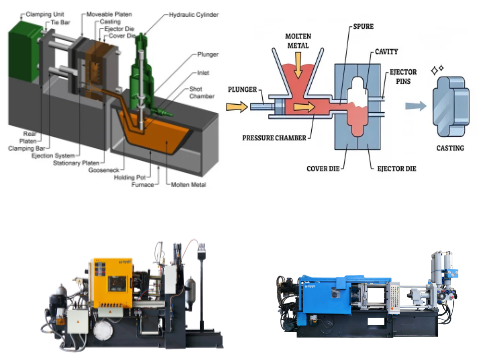

Die casting is a manufacturing technique whereby molten metal is injected into a mould and formed into the desired shape under high pressure. It is suitable for producing parts with complex designs, high precision requirements, and large production volumes. Commonly used metals for die casting include zinc, magnesium, and aluminium. However, due to their availability, cost, and performance characteristics, zinc and aluminium remain the most favoured choices.

Different methods of quality testing for die-casting products

- Visual Inspection

- Dimensional Verification

- Non-Destructive Testing (NDT)

- Pressure Testing

- Destructive Testing

- Microstructure and Chemical Analysis

- Process Control and Documentation

- Residual Stress Analysis

Visual Inspection

- Surface Defects: Check for cracks, porosity, cold shuts (incomplete filling), and flash (excess material) using magnifying glasses or microscopes.

- Surface Finish: Assess smoothness and texture with profilometers or surface roughness testers.

- Standards: Follow ASTM E505 for surface inspection guidelines.

Dimensional Verification

- Tools: Use calipers, micrometers, Coordinate Measuring Machines (CMM), and laser scanners.

- Tolerances: Ensure compliance with design specifications, considering thermal expansion effects.

- Standards: Refer to ISO 8062 for dimensional tolerances in castings.

Non-Destructive Testing (NDT)

- Radiographic Testing (X-ray/CT Scan): Detect internal voids, cracks, and inclusions (ASTM E155).

- Ultrasonic Testing: Identify subsurface flaws using high-frequency sound waves.

- Dye Penetrant Inspection: Apply dye to reveal surface cracks (ASTM E165).

- Eddy Current Testing: Assess conductivity and detect near-surface flaws in conductive materials.

Pressure Testing

- Leak Testing: Apply air/water pressure to check for leaks in components requiring airtight/watertight integrity.

Destructive Testing

- Mechanical Properties: Test tensile strength, hardness (Rockwell/Brinell), and impact resistance (ASTM E8, E10, E23).

- Porosity Analysis: Use density measurement or pycnometry to evaluate internal voids.

Microstructure and Chemical Analysis

- Metallography: Examine grain structure and defects via microscopy after sectioning and etching (ASTM E3).

- Spectrometry: Verify alloy composition using OES or XRF analyzers.

Process Control and Documentation

- Monitoring: Track parameters like pour temperature, cooling rates, and mold quality during production.

- Certification: Ensure material certifications (e.g., ASTM B179) and inspection reports are provided.

Residual Stress Analysis

- X-ray Diffraction: Measure residual stresses that could affect performance.

Application-Specific Considerations

- Critical Components: Aerospace or automotive parts may require advanced methods like CT scanning.

- Standards Compliance: Adhere to relevant ASTM, ISO, or industry-specific standards throughout.

By integrating these methods, manufacturers can systematically assess both surface and internal quality, ensuring the aluminium casting meets functional and safety requirements. The choice of techniques depends on the component’s criticality and application demands.

What is the best grade of aluminum for die casting?

The “best” cast aluminum grades of die casting depends on the specific application, desired properties (e.g., strength, corrosion resistance, castability), and the casting method (e.g., sand casting, die casting, or permanent mold casting). Below are the most widely used aluminum casting alloys and their key characteristics:

- Common Aluminum Casting Alloys

- Key Factors to Choose the “Best” Alloy

- Summary Table

- Final Recommendation

Common Aluminum Casting Alloys

- A356 / A356.2

- Properties: Excellent strength-to-weight ratio, good ductility, and weldability. Heat-treatable (T6 temper enhances strength).

- Applications: Automotive wheels, aerospace components, structural parts.

- Casting Method: Sand casting, permanent mold casting.

- 380 / A380

- Properties: High fluidity, excellent pressure tightness, and good machinability. Moderate strength and corrosion resistance.

- Applications: Engine brackets, housings, pump components.

- Casting Method: Die casting (most common).

- 319

- Properties: Good machinability, moderate strength, and thermal stability.

- Applications: Engine blocks, cylinder heads, transmission cases.

- Casting Method: Sand or permanent mold casting.

- 413 / A413

- Properties: Superior pressure tightness and corrosion resistance. Lower strength than 380.

- Applications: Hydraulic cylinders, marine components.

- Casting Method: Die casting.

- 356 / 356.2

- Properties: Similar to A356 but with tighter impurity controls. Heat-treatable for improved strength.

- Applications: Aerospace, automotive, and high-stress components.

- 535

- Properties: Excellent corrosion resistance (marine-grade), moderate strength.

- Applications: Marine hardware, boat components.

- LM25 (UK/EU Standard)

- Properties: High strength, good weldability, and corrosion resistance. Comparable to A356.

- Applications: Automotive and structural parts.

Key Factors to Choose the “Best” Alloy

- Strength Requirements:

- For high strength, choose heat-treatable alloys like A356 or 356.

- For moderate strength and cost-effectiveness, 380 or 319 are better.

- Casting Method:

- Die Casting: Use A380 or 413 (high fluidity).

- Sand/Permanent Mold Casting: Use A356, 319, or 535.

- Corrosion Resistance:

- 535 or 413 for marine/saltwater environments.

- Thermal Performance:

- A356 or 319 for components exposed to high temperatures (e.g., engine parts).

- Cost:

- A380 is cost-effective for high-volume die casting.

- A356 is pricier but offers superior mechanical properties.

Summary Table

| Alloy | Strength | Corrosion Resistance | Castability | Best For |

|---|---|---|---|---|

| A356 | High | Good | Moderate | Aerospace, automotive, structural |

| 380 | Moderate | Moderate | Excellent | Die-cast housings, engine parts |

| 535 | Moderate | Excellent | Moderate | Marine components |

| 319 | Moderate | Good | Good | Engine blocks, transmission cases |

| 413 | Low | Excellent | Excellent | Hydraulic/marine parts |

Final Recommendation

- For general-purpose die casting: A380 (balance of cost, fluidity, and strength).

- For high-strength structural parts: A356 (heat-treated to T6 temper).

- For marine environments: 535 or 413.

Always consult material datasheets and test prototypes under real-world conditions to validate performance. Standards like ASTM B179 (for casting alloys) or ISO 3522 can guide material selection.

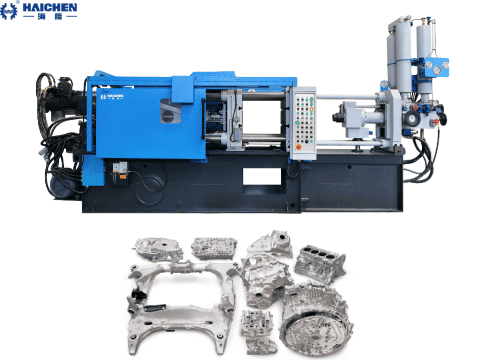

HAICHEN aluminium die casting machine company

Haichen is a Chinese company specializing in aluminum die-casting technology and equipment manufacturing. Its core business covers the research and development, production and supporting solutions of cold chamber die-casting machines.

- Core Technology and Equipment

- Application fields

- Technical advantages

- R&D and production strength

- Distinction from hot chamber die casting

- Industry cooperation and innovation

Core Technology and Equipment

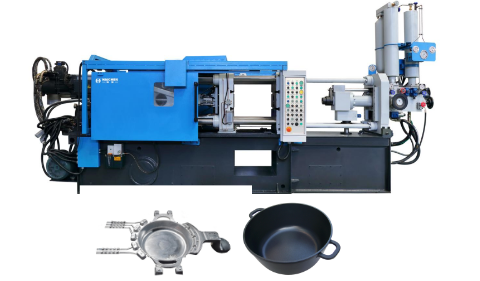

Haichen’s aluminum die-casting mainly uses cold chamber die-casting machines, which are suitable for high-melting-point alloys such as aluminum and magnesium (melting point over 700℃).

The cold chamber design separates the furnace from the injection chamber to avoid direct damage to the machine by high temperature and ensure stable production. Its die-casting machines cover a wide range of tonnage (500-30000 kN), and are equipped with servo hydraulic systems and energy-saving technologies, supporting multi-stage pressure and speed control to improve molding accuracy.

For example:

200-ton cold chamber die-casting machine (HCD 200-C): Suitable for precision aluminum parts such as automotive parts and instruments, equipped with PLC touch screen control, imported hydraulic components and digital temperature control furnace to ensure product quality.

880-ton cold chamber die-casting machine: specially designed for aluminum radiators, to achieve integrated molding, improve thermal efficiency and lightweight level.

Application fields

Haichen’s aluminum die-casting technology is widely used in many industries:

Automotive industry: production of parts for traditional fuel vehicles and new energy vehicles, such as engine parts, structural parts, etc., using the lightweight advantages of aluminum alloy to improve energy efficiency.

Radiator manufacturing: through aluminum die-casting to achieve integrated molding of radiators, compact structure and uniform heat conduction.

Household products: such as aluminum pots, cookers, etc., the die-casting process makes the products thick and uniform, and not easy to deform when heated.

LED lamps: The aluminum shell has both high strength and heat dissipation performance to ensure long-term stable operation of the lamps.

Technical advantages

Advanced technology: supports vacuum casting, extrusion casting and intelligent production, reduces defects such as pores, and improves product density.

Four-stage injection control: compared with the traditional three-stage control, Haichen cold chamber die-casting machine realizes a smooth transition from slow shot → fast shot → pressurization, optimizes the flow of aluminum liquid, and reduces turbulence and oxidation.

Intelligent system: Siemens PLC and Mitsubishi Electric components are used, multi-language operation interface is supported, injection curve is monitored in real time, and process traceability is ensured.

R&D and production strength

The factory is located in Ningbo, with 5,000+ square meters of standardized workshops and large processing centers, and has full-chain capabilities from design to delivery.

Certified by CE and ISO 9001, core hydraulics and seals are made by international brands such as Bosch Rexroth and Schneider to ensure equipment durability.

Provide value-added services such as mold design and melt flow analysis to assist customers in optimizing production processes.

Distinction from hot chamber die casting

Haichen clearly distinguishes the application scope of cold chamber and hot chamber die casting machines:

Hot chamber die casting machines are only used for low melting point alloys such as zinc and lead (melting point below 450°C), because the high temperature of aluminum will corrode the components in the hot chamber.

Cold chamber die casting machines are designed for aluminum and magnesium, and use external furnaces to avoid high temperature damage to the injection system.

Industry cooperation and innovation

Haichen works closely with customers to promote large-scale die-casting island integration technology, such as the 8800T die-casting machine for one-piece body molding of new energy vehicles, demonstrating its cutting-edge layout in the field of “integrated die-casting”.

Haichen has become an important supplier of global aluminium die casting equipment and solutions with its cold chamber aluminium die casting technology advantages, wide application scenarios and continuous technological innovation.

Contact us to get more information about aluminum alloy die-casting production lines.