Die casting mold cost range from tens to hundreds of thousands of dollars.

What is the struture of die casting mold? A die-casting mold is essentially a high-precision, high-pressure-resistant steel device composed of a base, cavity/core, gating system, cooling system, venting/sealing system, demolding system, and various guiding/positioning elements. Each subsystem works together to ensure that molten metal is filled, solidified, and smoothly ejected in a very short time, thereby achieving high-quality, high-volume production of metal parts.

Molds play a vital role in the die casting process, so their cost must be carefully evaluated. Mold design and engineering considerations, such as the number of cavities, complexity, and surface treatment requirements, all affect the total cost. Estimating tooling costs includes material, machining, and surface preparation costs, as well as life expectancy and maintenance requirements.

How much does a casting mold cost? To discuss this topic, we will analyse from die casting mold cost formula, to factors affecting die casting mold cost, process cost comparison and additional cost.

- Die casting mold cost formula

- Factors affecting Die casting mold cost

- Process Cost Comparison

- Additional Costs

- Haichen die casting customized mold

Die casting mold cost formula

A die casting mould cost = Material fee+ Design fee + Processing fee + Profit + VAT + Trial fee + Packaging & Transportation fee

Among them:

Material costs account for 15-30% of the total cost;

Design fee accounts for 10-15%;

Processing fee and profit account for 30%-50%;

The trial mold fee is controlled within 3%-5%;

Packaging and transportation costs are calculated according to the actual or at 3%.

Factors affecting Die casting mold cost

- Complexity of the mold

- Material cost

- Design and Manufacturing Costs

- Service life and maintenance

- Raw material price fluctuation

Complexity of the mold

- The complexity of a mold is one of the main factors affecting price.

- For example, molds with complex shapes, multiple cavities, or special features such as cooling channels require more advanced engineering and manufacturing processes, which can significantly increase the cost.

- Simple molds can cost in the thousands of dollars, while complex molds can cost over $100,000.

Material cost

- Die-casting molds usually use high-strength steel (such as H13, SKD61, etc.), the price of these mould materials is high, especially when the mold needs to withstand high pressure and high temperature environment.

- The choice and quality of materials directly affect the service life of the mold and cost.

Design and Manufacturing Costs

- The design and manufacturing cost of a mold includes CAD/CAE analysis, mold design, machining and mold trial.

- The design cost accounts for 10-30% of the total cost of the mold, while the mold trial cost is usually controlled within 3-5%.

Service life and maintenance

- The service life of a mold also affects its price. High-quality molds have a higher initial investment, but their durability and long-term use reduces maintenance costs.

- Conversely, low quality molds may require frequent replacement, increasing overall costs.

Raw material price fluctuation

- Fluctuations in the price of raw materials (such as aluminum, zinc, magnesium, etc.) will also affect the cost of die-casting molds.

- For example, the price of aluminum will directly push up the material cost of the mold.

Process Cost Comparison

- Vacuum Casting

- 3D Printed Sand Molds

- Casting

Vacuum Casting

Extremely low mold costs (requires only a master mold and silicone mold), suitable for small batches of less than 100 pieces, avoiding injection molds costing €5,000–€50,000+.

3D Printed Sand Molds

Approximately €5 per liter, significantly lower than metal printing (€300–€400 per kg).

Casting

Casting molds are more suitable for large/complex parts, but their mechanical properties are weaker than forging.

HAICHEN’s Role in Achieving Cost-Effective Mold Solutions

HAICHEN provides more than machines; we offer knowledge to help you make smart mold investments.

- Optimizing Mold Design for a Automotive Client

- HAICHEN’s Advantage Of Integrated Process Knowledge

Optimizing Mold Design for a Automotive Client

One of Haichen’s customers needed a mold for a new engine bracket. The first design had very complex cores, leading to a high quote. HAICHEN engineers reviewed the part function with the client. We suggested a minor design change that simplified the core action. This change reduced the mold’s complexity without affecting the part’s strength. The final die casting mold cost was 20% lower than the initial quote. The mold also runs more reliably in the HAICHEN press, reducing cycle time.

HAICHEN’s Advantage Of Integrated Process Knowledge

Our experience shows that the best die casting mold cost is one that delivers reliable performance in a HAICHEN machine. We understand how mold design affects cycle time, part quality, and machine wear. We guide clients to make choices that lower total production cost, not just the initial mold price. This full-system view is our key advantage.

Additional Cost

- Maintenance Costs

- Material and Scrap Rates

- Automation Investment

Maintenance Costs

Molds require regular maintenance, increasing costs over time.

Material and Scrap Rates

Aluminum/zinc alloy prices and scrap rates (5–10%) impact total costs.

Automation Investment

Highly automated equipment increases initial costs.

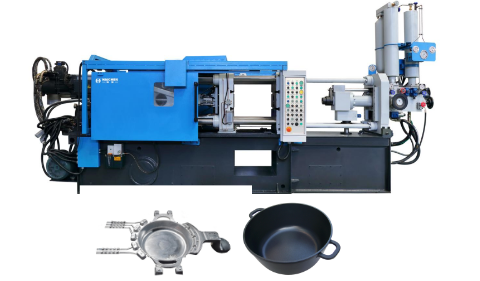

Haichen die casting customized mold

Haichen’s die casting machine molds can be customized according to customer’s needs with flexible price. With product information, we can customize accurate die casting molds for you. Besides mold, we aslo supply cold chamber and hot chamber die casting machines.

Our die casting molds are capable of producing parts with complex geometries and fine details, including thin-walled structures, small features and internal structures.

The price of die-casting molds mainly depends on the complexity of the mold, material costs, design and manufacturing costs, production batch, process accuracy requirements and service life and other factors. In addition, regional differences, market supply and demand and raw material price fluctuations will also have an impact on the final price.