Die casting machine consume limit value of a certain die-casting machine is about 50 kW·h, and the energy consumption per cycle is about 1kW·h/cycle.

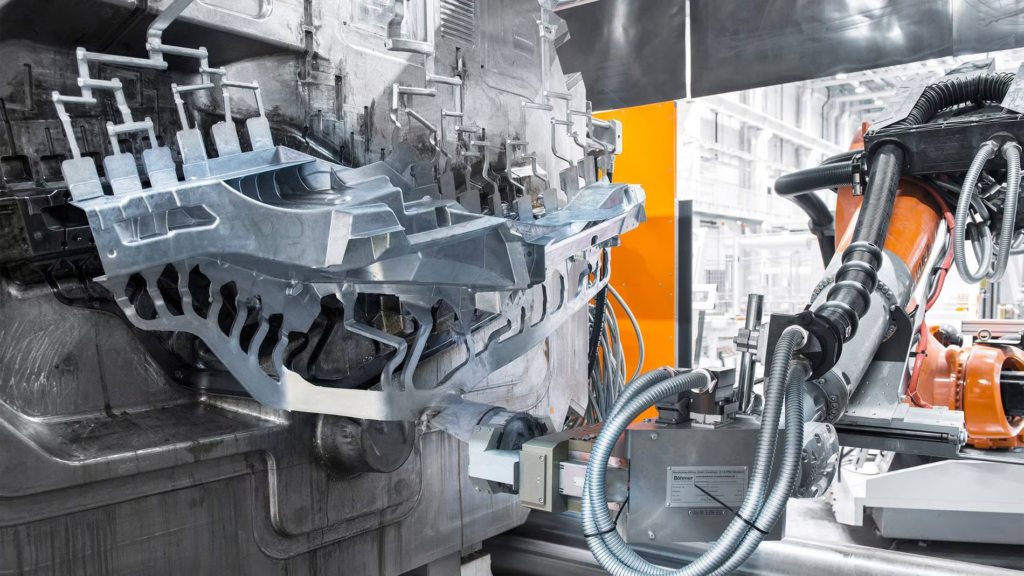

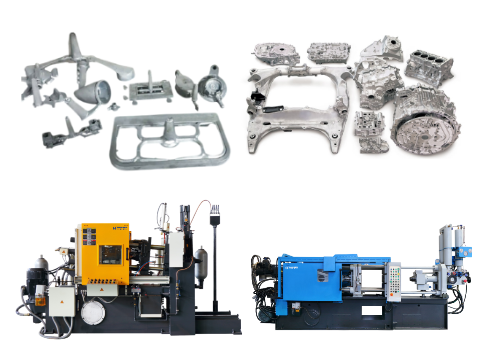

Die-casting machines are mainly divided into two types: hot chamber and cold chamber.

Different types of machines are suitable for metals with different melting points.

For instance, hot chamber machines are typically used for low-melting-point metals such as zinc and magnesium.

While cold chamber machines are suitable for high-melting-point metals like aluminum and copper.

This may affect their energy consumption, as high-melting-point metals may require more energy to remain in a molten state.

The power consumption per pound of high-pressure die-casting facilities is 6.60 kWh.

Converted to tons, a larger figure may be required.

For example, each ton of aluminum may require several thousand kilowatt-hours.

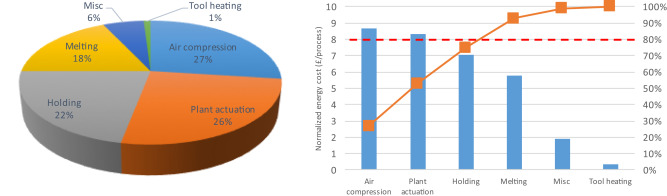

In addition, the oil pump motor of the hydraulic system accounts for more than 80% of the total energy consumption, which indicates that the hydraulic system is the main energy-consuming part.

In addition, the energy consumption for smelting metals is also very high.

The smelting stage accounts for 40% to 60% of the total energy consumption of the entire process.

While the actual casting process makes up the remaining part.

For example, the average power consumption per ton of castings is approximately 5,603 kilowatt-hours, but there are significant differences among different factories.

Die casting machine consume parameters

- Power parameters of large die-casting machine

- The power parameters of a small die-casting machine

- Power consumption after energy-saving transformation

- Other data

Die casting machine consume varies depending on the model and production conditions.

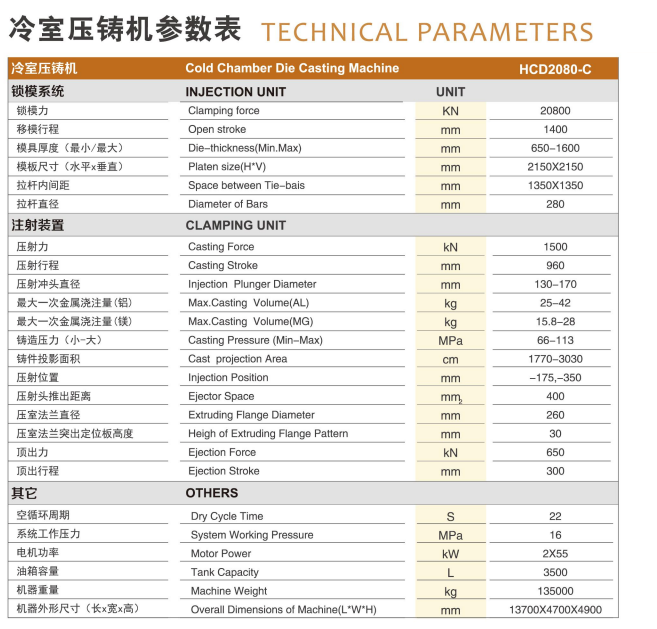

Power parameters of large die-casting machine

According to this, the motor power of a commonly used 1200T die-casting machine may be between 110-160kW.

Which indicates that the die casting machine consume of large-scale die-casting machine is higher.

Especially in the case of continuous work, the electrical energy consumption is considerable.

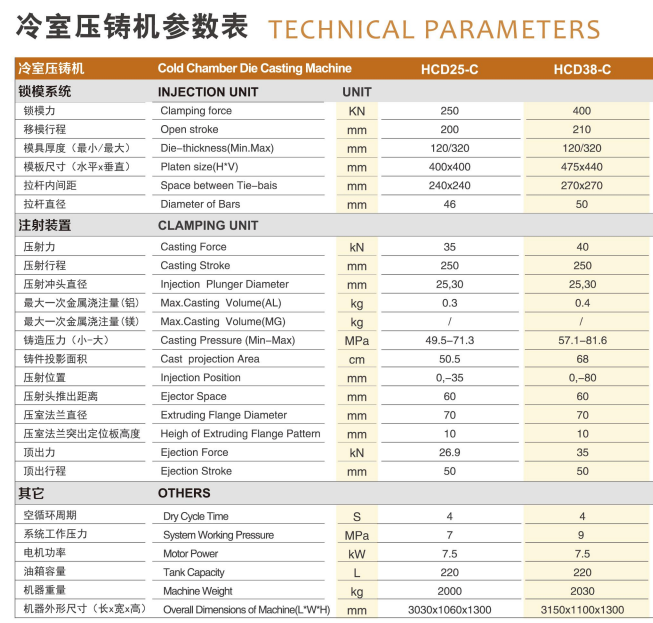

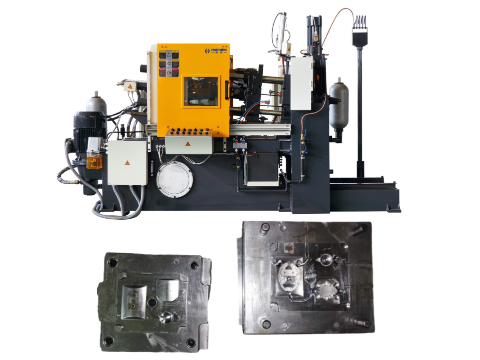

The power parameters of a small die-casting machine

It is mentioned that the power of a 25-ton die-casting machine is about 7.5kW, while the power of the supporting melting furnace is 10kW, and the total electricity consumption per hour is 18kW.

Power consumption after energy-saving transformation

It is mentioned that the die-casting machine that has undergone energy-saving transformation.

Such as the 2500T die-casting machine, consumes 27.66 kWh (about 27.66kW) per hour in the energy-saving state.

While the motor equipped with the 2000T machine consumes 19 kWh (about 19kW) per hour in the energy-saving state.

Other data

It is pointed out that the power of a medium-sized die-casting machine is usually more than 100 kW, while the power of a small die-casting machine with supporting equipment is 37 kW.

Energy consumption of the die-casting machine

- Power consumption of the oil pump of the hydraulic system

- Power consumption of cooling water circulating pump

- Power consumption of other equipment

- Energy consumption in standby mode

- Differences in energy consumption for specific metals

Power consumption of the oil pump of the hydraulic system

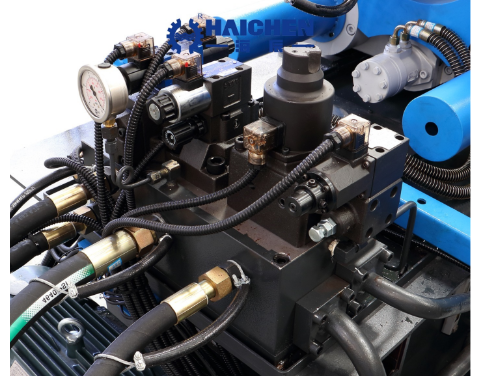

The oil pump motor of the hydraulic system is the main energy consumption part of the die-casting machine.

And its power consumption accounts for more than 80% of the total energy consumption of the entire die-casting machine.

The electricity consumption of the heater is used to heat the metal to reach the melting temperature, which also accounts for a considerable proportion of the energy consumption.

Power consumption of cooling water circulating pump

In the die-casting workshop, there are usually multiple die-casting machines sharing a cooling water circulating pump, and this part of the energy consumption cannot be ignored.

Power consumption of other equipment

This includes the power consumption of equipment such as air compressors, exhaust fans, and cooling towers.

Energy consumption in standby mode

The die-casting machine also consumes a lot of power in standby mode, accounting for 40% of the total energy consumption.

Differences in energy consumption for specific metals

In a magnesium alloy die casting machine, for example, the energy consumption of melting and holding magnesium alloys accounts for one-third of the total electrical energy.

Reduce energy consumption

- Inverter application

- PQ Valve Overflow Control System

- Duplex vane pump

- Intelligent control system

Through closed-loop control, the servo motor system adjusts the motor speed and oil pump supply according to the actual demand.

Which avoids the high-pressure throttling and overflow phenomenon in the traditional hydraulic system, thereby significantly reducing energy consumption.

For example, servo energy-saving motor of the hydraulic system to save 30%-40%.

The servo motor system also has high response characteristics, short start-up time, fast response.

And can quickly respond to control signals to achieve motion control or die-casting control, shorten the working cycle, and improve production efficiency.

Inverter application

Adjust the speed of the oil pump motor through the inverter, realize automatic adjustment according to the pressure and flow parameters required for the work.

And transform the quantitative pump into a variable pump to reduce the energy loss caused by high-pressure interception.

For example, through the transformation of the inverter, it is expected that the power saving rate can reach 20%~60%.

PQ Valve Overflow Control System

Combined with the PQ Valve Relief Control System, more accurate pressure and flow control can be achieved, improving motor efficiency and reducing energy consumption.

The high efficiency and low starting current of the servo motor can significantly increase the productivity of the equipment and reduce energy waste.

Duplex vane pump

Duplex vane pump is used to improve the efficiency of the pumping station and reduce energy consumption.

For example, Japan’s Toshiba DC650J-MX die-casting machine significantly reduces the amount of heat generated and cooled by the hydraulic system by using a double-vane pump.

Intelligent control system

Through the intelligent control system, combined with the servo system, it can effectively improve the production efficiency and improve the working environment.

For example, the national energy innovation die-casting machine uses servo to inject new vitality, and the servo system adopts closed-loop speed control.

Which improves the repeatability of the injection running position and the consistency of product accuracy.

Die-casting machine energy consumption

Die casting is an energy-intensive process, so the specific parameters of the casting process itself will affect power consumption.

The larger the die-casting machine is, the greater the clamping force will be, and naturally, the more power is required.

Hot chamber smelters using crucibles also require specific power to melt and maintain molten metals.

Apart from die-casting machines, other equipment such as cooling systems, conveyor belts and edge trimming machines will also increase the overall energy consumption.

Die Casting and Energy Consumption

Die casting can be one of a factory’s most energy-intensive processes, which creates sustainability and cost issues.

As you might imagine, heating metal to a melting point takes a lot of energy. Cooling these materials and moving them around also consumes electricity, leading to some substantial costs.

Energy consumption can account for 25% of die casting costs, so you can see why manufacturers would want to save energy.

Figuring out how to lower electricity consumption is not always as straightforward as you might think, though. Some parts of the process aren’t possible without using a certain amount of energy.

If you’re going to melt metal, you need a lot of heat, and there’s no going around that.

Since liquid metals aren’t particularly light, injecting them into a cast also takes a lot of pressure, which takes energy.

Therefore, Haichen‘s task of identifying areas where manufacturers can reduce energy consumption might be quite challenging.

As a result, finding places where manufacturers can cut down on energy consumption can be challenging.

Surprisingly, though, 40% of die casting energy consumption happens while the machines are in standby mode.

Manufacturers may not be able to reduce the consumption rate of processes like heating by much, but there’s still a lot to improve.

Haichen die casting machine

- Reduce energy waste

- Improve motor efficiency

- Optimize equipment operation

- Reduced maintenance costs

- Improved working environment

Reduce energy waste

The energy loss of traditional hydraulic systems in the process of high-pressure throttling is as high as 25%~70%.

And the application of servo motor system and frequency converter can significantly reduce this energy waste.

Improve motor efficiency

The total efficiency of servo motor (including drive) is about 10% higher than that of asynchronous motor.

And the output of 2 times the rated torque at the rated speed only needs 2 times the power supply current, which is much lower than that of ordinary asynchronous motor.

Optimize equipment operation

Through closed-loop control and intelligent control system, more accurate pressure and flow control can be realized.

Reducing energy waste when there is no operation, and improving the operation efficiency of the equipment.

Reduced maintenance costs

The application of servo motor systems and frequency converters reduces wear and tear and maintenance needs of equipment, extends equipment life, and reduces maintenance costs.

Improved working environment

The application of servo motor system and frequency converter also brings the advantages of low noise and low temperature rise, which improves the working environment.