When we choose a cold chamber die casting machine, we will start to consider the characteristics of the metal materials of our target products, production requirements, product complexity, cost, and equipment performance.

It is also a very necessary factor to select professional technicians to operate and maintain the cold chamber die casting machine because of the relatively complex technical difficulties in maintenance and operation.

Selecting a cold chamber die casting machine involves a systematic approach to ensure it meets your production needs, material requirements, and budget. Here’s a structured guide:

Tips for choosing aluminum alloy cold chamber die casting machine

- Material Considerations

- Part Specifications

- Clamping Force

- Shot Capacity

- Injection Parameters

- Machine Dimensions

- Automation & Controls

- Energy Efficiency

- Safety Features

- Manufacturer & Support

- Cost Analysis

- Testing & Trials

Material Considerations

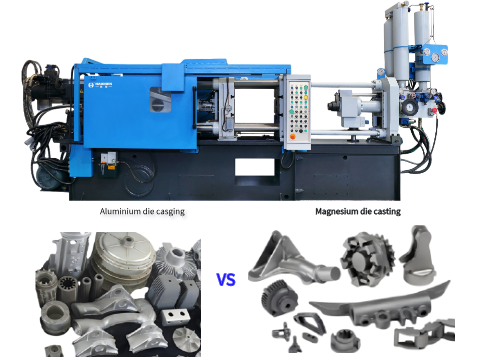

- Metal Type: Confirm the machine is compatible with high-melting-point metals (e.g., aluminum, brass, copper). Each metal has specific thermal and pressure requirements.

- Melting Temperature: Ensure the machine’s furnace can handle the metal’s melting point (e.g., ~660°C for aluminum).

Part Specifications

- Size/Weight: Calculate the part’s volume and weight, including overflow and biscuit. Use the formula:Shot Weight=Part Volume×Metal Density+Overflow/BiscuitShot Weight=Part Volume×Metal Density+Overflow/Biscuit

- Projected Area: Determine the area perpendicular to the clamping direction to calculate clamping force.

Clamping Force

- Use the formula:Clamping Force (tons)=Projected Area (cm²)×Injection Pressure (kg/cm²)1000Clamping Force (tons)=1000Projected Area (cm²)×Injection Pressure (kg/cm²)

- Injection Pressure: Varies by material (e.g., 400–1000 kg/cm² for aluminum).

Shot Capacity

- Ensure the machine’s shot capacity exceeds the total weight of the part, biscuit, and overflow. For aluminum, a 500 cm³ part may require ~1500g shot capacity.

Injection Parameters

- Pressure: Adjust based on part complexity (higher for thin walls).

- Speed: Typically 1–5 m/s for aluminum to prevent premature solidification.

Machine Dimensions

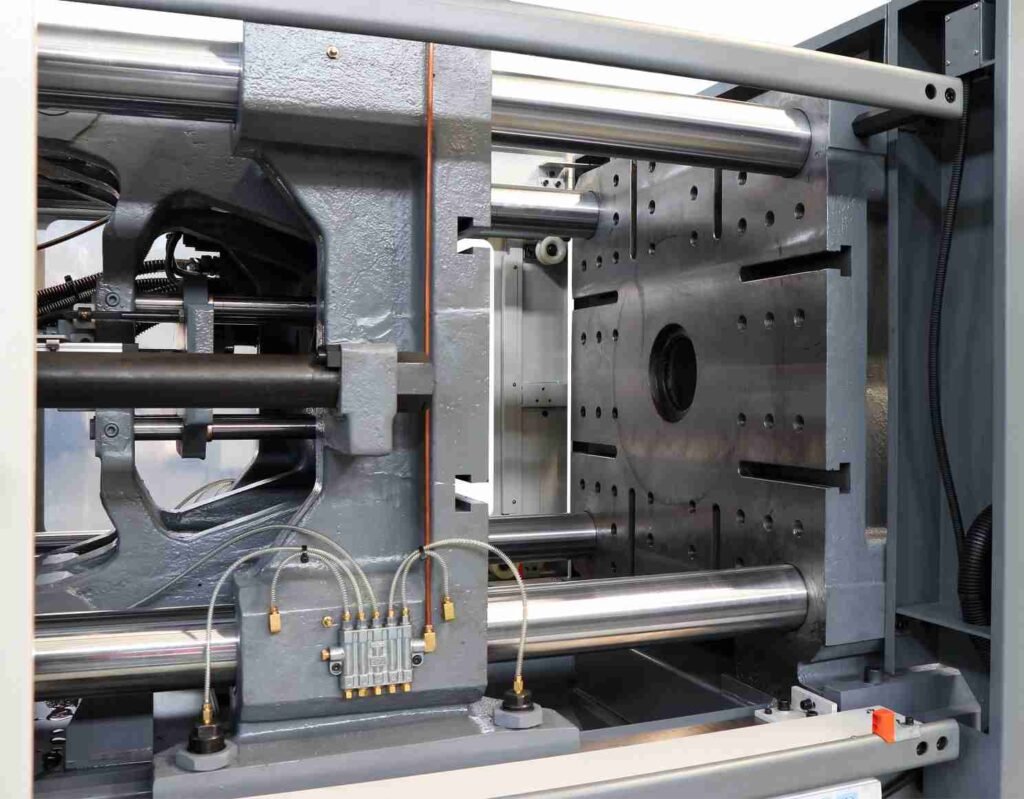

- Platen Size: Must accommodate the die dimensions.

- Die Height/Stroke: Ensure sufficient die opening height and stroke length for part ejection.

Automation & Controls

- Opt for PLC-based systems with real-time monitoring, programmable settings, and data logging for consistency.

Energy Efficiency

- Prioritize machines with variable speed drives or energy-saving modes to reduce operational costs.

Safety Features

- Look for safety interlocks, emergency stops, light curtains, and compliance with industry standards (e.g., OSHA, CE).

- This is really important in Selecting die casting machine.

Manufacturer & Support

- Choose reputable brands with reliable customer service, spare parts availability, and warranty options.

Cost Analysis

- Balance upfront costs with long-term operational expenses (energy, maintenance, downtime).

Testing & Trials

- Conduct trials with production dies to validate machine performance under real conditions.

Example Calculation:

- Part: Aluminum alloy, projected area = 500 cm², injection pressure = 600 kg/cm².

- Clamping Force: 500×600/1000=300500×600/1000=300 tons.

- Shot Weight: 1500g (part + overflow).

- Machine Requirements: ≥300 tons clamping force, ≥1500g shot capacity, platen size accommodating the die.

By following these steps, you can systematically Selecting a cold chamber die casting machine tailored to your production needs.

Haichen Cold chamber die casting machine

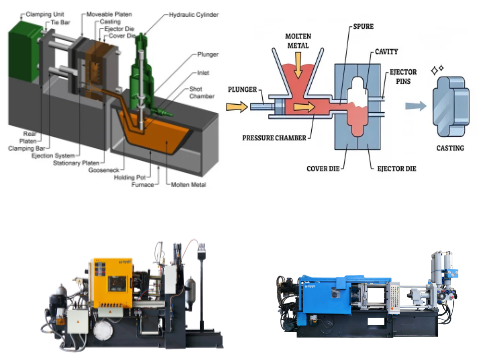

Haichen cold chamber die casting machine is a high-pressure die casting equipment for metal casting, mainly used for precision casting of high melting point metals such as aluminum, zinc, and magnesium.

The following is detailed information about Haichen cold chamber die casting machine:

- Product features and technical advantages

- Application field

- Equipment specifications and performance

- Market position and brand advantages

- Innovation and development

Product features and technical advantages

Haichen cold chamber die casting machine adopts advanced design and manufacturing technology, complies with international standards (such as JB/T8083-2000, JB/T8084.1-2002, etc.), and combines European die casting machine standards (such as DIN 17250) for optimization, ensuring the high performance and reliability of the equipment.

Its main features include:

Multi-stage injection system

Haichen cold chamber die casting machine usually adopts a four-stage injection system (slow filling, fast filling, fast acceleration and enhanced injection), which can effectively control the flow speed of aluminum liquid and improve product quality.

Fully closed-loop control system

Some models (such as HDC series) use Siemens control technology to achieve precise control of injection pressure, speed and holding time, ensuring high-quality and high-stability casting production.

Intelligent management function

Some models support intelligent quality management system, which can automatically detect unqualified products and stop production, thereby improving production efficiency and product quality.

High efficiency and energy saving

Haichen cold chamber die casting machine adopts servo hydraulic system, which has the characteristics of low energy consumption, fast response and efficient heat dissipation.

Application field

Haichen cold chamber die casting machine is widely used in automobiles, motorcycles, communication equipment, instruments and meters, household appliances, building hardware and other fields, suitable for precision casting of non-ferrous metals such as aluminum, zinc, copper and magnesium.

For example, its 880-ton cold chamber die casting machine is used to produce high-precision aluminum radiators.

Equipment specifications and performance

Haichen cold chamber die casting machine has a tonnage range from 300 tons to 5,000 tons, which can meet the production needs of enterprises of different sizes.

Its main technical parameters include:

Maximum range: 180 mm.

Maximum injection force: up to 950 tons.

Mold thickness: maximum 400 mm.

Sand shooting speed: up to 9 m/s.

Market position and brand advantages

As China’s leading die-casting machine manufacturer, Haichen has been exporting high-pressure die-casting machines since 2005 and has established a good reputation in domestic and foreign markets.

Its cold chamber die-casting machine products are known for their “reliability and durability” and are trusted by customers.

Innovation and development

Haichen continues to innovate in technology and has launched the HDC series of cold chamber die-casting machines, which have many innovative designs.

Such as double closed-loop control, real-time monitoring system and intelligent quality management system, further improving the performance of the equipment and user experience.

In addition, its cold chamber die-casting machine also supports network remote monitoring, which is convenient for users to grasp the production status in real time.

Haichen cold chamber die-casting machine occupies an important position in the global die-casting machine market with its high performance, high precision and intelligent characteristics, providing customers with efficient and reliable casting solutions.

Choose Haichen as your die casting supplier and let us help your business~

You may also want to know

- What are the 2 types of die casting machines?

- Why would you choose cold chamber die casting over hot chamber die casting?

- What is the cold chamber method of die casting?

Send us an e-mail and getting more details.