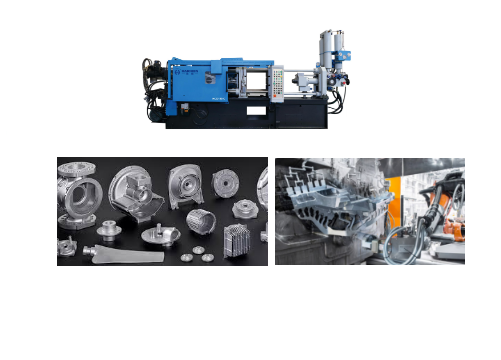

High pressure die casting machine industry application includes automotive, aerospace industry, electronic equipment industry, etc.

High Pressure Die Casting Machine (HPDC) is an efficient and economical manufacturing process. It widely uses in many industrial fields. Especially in the automotive, aerospace and electronic equipment industries. Beyond the automotive industry, high-pressure die-casting machines are widely used in a variety of industries, including aerospace, electronics, household products, medical devices, industrial machinery, defense, packaging, lighting, and toys.

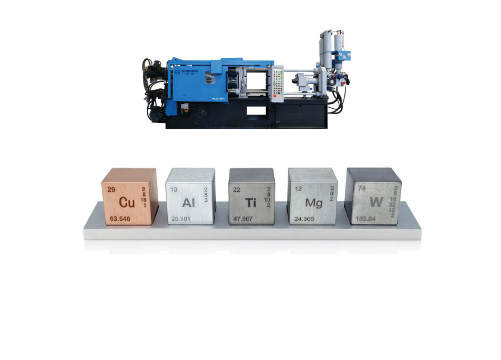

These applications benefit from HPDC’s high efficiency, precision, and material versatility (such as aluminum, magnesium, and zinc alloys), enabling the production of lightweight, high-strength, and cost-effective components.

This technology produces parts with high dimensional accuracy and complex geometry by rapidly injecting molten metal into the mold cavity under high pressure and solidifying it in a short time.

Automotive Industry

- Powertrain Components

- Structural and Chassis Components

- Large Body Components

High-pressure die casting technology is most widely used in the automotive industry. mainly for the production of lightweight metal parts.

For example, die castings of aluminum, magnesium and zinc alloys are used to manufacture key parts such as engine blocks, transmission housings, and body structures.

Haichen have rich experience of producing high pressure cold chamber die casting machine produce aluminium alloy crankcase.

Powertrain Components

- HPDC is widely used in the production of key components such as engine blocks, transmission housings, cylinder heads, and oil pans.

- Aluminum and magnesium alloy die-castings achieve lightweighting while maintaining structural strength, improving fuel efficiency and vehicle handling.

Structural and Chassis Components

- These include engine mounts, cross-car beams, brake system components, and suspension parts.

- HPDC-produced parts exhibit high rigidity and dimensional stability, directly enhancing vehicle safety and stability.

Large Body Components

- Automakers such as Tesla use HPDC technology to manufacture front and rear end monolithic components (Giga Casting).

- This technology consolidates 70-100 traditional parts into a single casting, significantly reducing production complexity and improving efficiency.

Aerospace Industry

- Engine Components

- Landing Gear and Structural Parts

- Avionics Equipment Housings

- Material Advantages

In the aerospace field, HPDC technology uses to produce high-strength, high-heat-resistant magnesium alloy parts. Such as aircraft structural parts and engine components.

Due to the low density and good mechanical properties of magnesium alloy, it has significant advantages in reducing the weight of aircraft.

In addition, the HPDC process can produce parts close to the net shape, reducing the need for subsequent processing, thereby improving production efficiency.

Engine Components

- HPDC is used to produce precision aircraft engine components (such as turbine blades and combustion chamber parts).

- Because it can withstand high-temperature and high-pressure environments while meeting lightweight requirements.

Landing Gear and Structural Parts

- High-strength parts such as landing gear components, fuselage structural frames, and wing ribs.

- They can be manufactured using HPDC to achieve complex geometries and high precision while reducing weight.

Avionics Equipment Housings

Zinc/aluminum alloy die-casting is used to ensure electromagnetic shielding, lightweight construction, and structural stability for radar and navigation equipment housings and brackets.

For example, Haichen use zinc alloy die casting to produce zinc pipe couplings, zinc alloy medals.

It can produce with mass production and different complex shapes.

Material Advantages

- Lightweight Alloy Applications: Aluminum, magnesium, and zinc alloys (such as high-strength aluminum-titanium alloys) are widely used in the aerospace industry.

- HPDC can fully utilize their strength-to-weight ratio advantages, reducing fuel consumption and improving flight efficiency.

- High Precision and Surface Quality: The HPDC process can meet the stringent tolerance requirements of aviation components. (Such as aerodynamic shape accuracy), which to reducing subsequent processing costs.

Electronic equipment industry

- Precision Structural Parts and Housings

- Cooling Systems

- Functional Components

HPDC technology also uses to produce small precision parts in electronic equipment, such as battery housings and heat sinks.

These parts usually require high precision and good surface quality, and the HPDC process can provide smooth surfaces and high dimensional consistency, thus meeting the strict requirements of electronic equipment for part quality.

Precision Structural Parts and Housings

HPDC technology is widely used in the manufacture of key structural components for electronic devices, such as housings, brackets, and terminals.

- These components require high dimensional accuracy, lightweight construction, and complex geometries to meet the demands of miniaturization in electronic products.

- Die-casting machines efficiently produce consumer electronic components such as mobile phone housings and laptop computers.

- By injecting molten metal (such as aluminum and magnesium alloys) under high pressure, ensuring surface finish and structural strength.

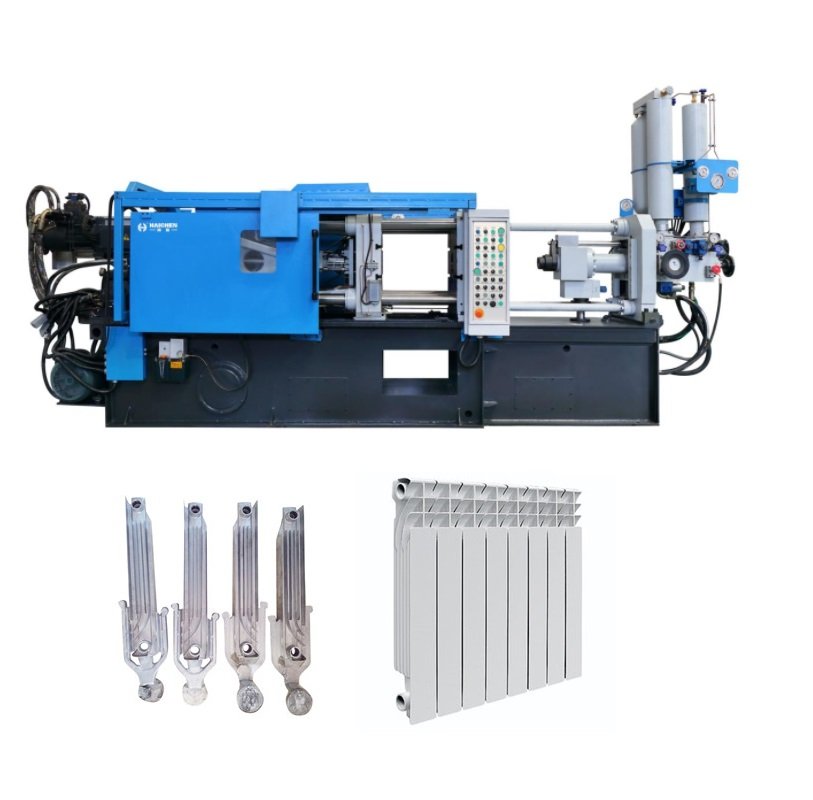

Cooling Systems

- Electronic equipment requires extremely high heat dissipation performance.

- HPDC can produce high-thermal conductivity heat sinks, motor housings, and other components to address heat generation issues.

Functional Components

- Electronic functional parts such as connectors and switches also rely on HPDC to ensure conductivity, corrosion resistance and long-term reliability.

- For example, Haichen use HDPC produce aluminium raidator heater.

Haichen produce high pressure die casting machine for more than 10years. It enabling the mass production of complex, high-strength metal components. A primary application is in the automotive sector, manufacturing essential parts like aluminium cookwares, radiator heater, zinc alloy medals, joint pipe couplings They are equally vital in consumer electronics for producing lightweight, intricate housings, and in the home appliance industry for durable internal frameworks.

Furthermore, Haichen machines support the production of industrial hardware, power tools, and telecommunications equipment. Their versatility, precision, and efficiency make them any industry requiring high-volume, high-integrity aluminum, magnesium, or zinc alloy castings.

Other industrial applications

- Medical Devices and Healthcare Equipment

- Industrial Machinery and Equipment

In addition to the major industries mentioned above, HPDC technology is also used to produce metal parts in household appliances, tools and other industrial equipment.

For example, by optimizing mold design and cooling channel layout, the production efficiency and quality of parts can be further improved.

Medical Devices and Healthcare Equipment

- HPDC is used to produce medical device components, such as instrument housings, surgical tools, and diagnostic equipment, requiring high precision, sterility compatibility, and durability.

- For example, instrument housings and brackets are used as structural components in medical devices. HPDC has applications in the medical device sector, producing high-precision components.

Industrial Machinery and Equipment

- This includes agricultural machinery, packaging machinery, locks, and general industrial parts.

- HPDC offers high strength and wear resistance, making it suitable for heavy or precision equipment.

Emerging technologies and future trends

With the development of additive manufacturing (such as selective laser melting SLM), HPDC processes are gradually combining AM technology to optimize mold design and production processes. For example, SLM technology can be used to manufacture complex mold components. Thereby reducing traditional processing steps and reducing costs

In addition, the HPDC process also shows potential in the production of large parts (such as sliders). It indicates that it may be further expanded to larger-scale production in the future development trends of die casting.

High pressure die casting machines have important application value in many industrial fields due to their high efficiency, economy and ability to produce parts with complex shapes. With the advancement of technology and the application of new materials, HPDC process will play a more important role in the future manufacturing industry.

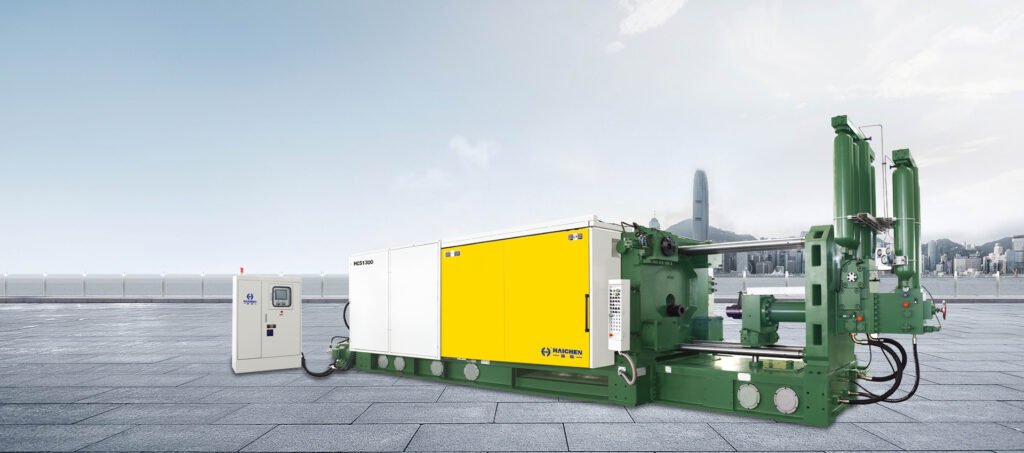

Haichen die casting machine

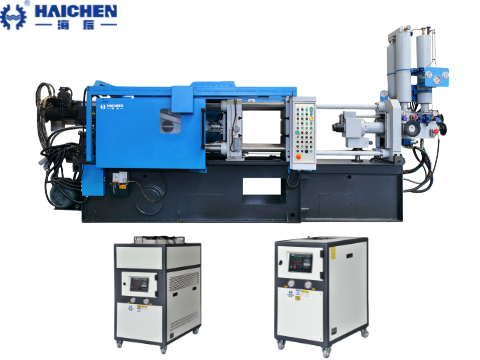

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.