Injection Unit of die casting maintenance is crucial for consistent production quality and minimizing downtime.

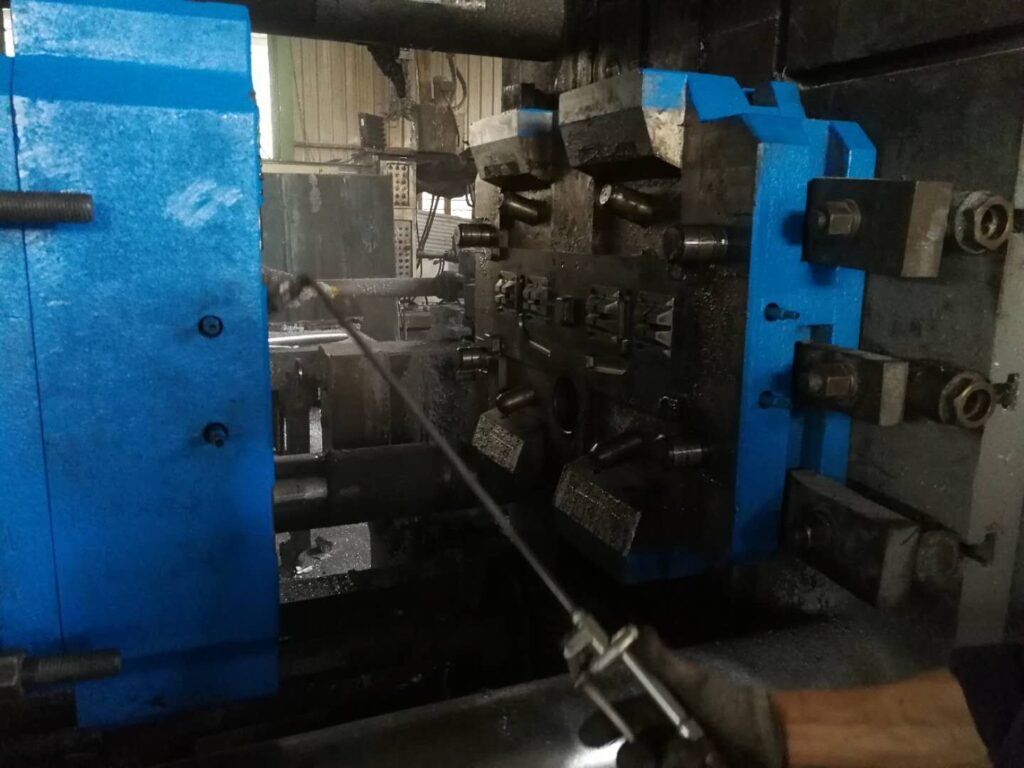

The injection unit of the die casting machine is responsible for accurately metering and injecting molten metal into the mold cavity under high pressure and at high speed.

Any degradation in its performance—such as plunger wear, pressure loss, or misalignment—can immediately lead to defects like short shots, porosity, or dimensional inaccuracy, resulting in increased scrap rates and unplanned downtime.

Therefore, systematic and proactive maintenance of the injection unit is not merely a routine task but a critical strategy for ensuring consistent product quality, maximizing equipment uptime, and controlling long-term production costs.

Importance of maintenance and industry standards

- Equipment safety and life

- Process stability

Equipment safety and life

National standard requirements: GB/T 25711-2010 stipulates that the maintenance manual must include periodic inspection procedures. Such as hydraulic system pressure testing.

Cost-effectiveness: Regular maintenance can reduce 40% of unplanned downtime and avoid hydraulic oil contamination due to leakage.

Process stability

The matching of clamping force and injection force directly affects the sealing of metal liquid. Large die-casting machines (>6000T) need to check the displacement of the large lever nut every week.

Temperature fluctuations of ±5℃ can cause shrinkage defects, and thermocouples need to be calibrated.

Injection Unit of die casting maintenance

Maintaining the injection unit of a die casting machine is essential to production. In this article, we will share practical maintenance tips to help you extend the life of your equipment. And maintain stable performance. Routine care and regular overhauls are key, and maintenance work of different sizes has different effects on the equipment.

- Regular Inspection

- Lubrication

- Cleaning

- Calibration

- Training

Regular Inspection

The daily maintenance of the injection unit of the die-casting machine must first be carried out regularly. The operator needs to carefully check the status of each component, focusing on three aspects:

- Wear and leakage: Check whether there are cracks in the hydraulic cylinder, observe whether there are abnormal wear marks on the surface of the plunger. And confirm the oil leakage of all sealing points;

- Structural integrity: Confirm the centering accuracy of the injection mechanism to prevent the misalignment of components from affecting the running trajectory;

- Function verification: Test the stability of the injection pressure to ensure that the parameter fluctuation is within the allowable range (it is recommended to refer to the standard value of the equipment manual).

These inspections can help to detect potential problems in time. For example, plunger wear can lead to inaccurate injection volume. And hydraulic cylinder cracks may cause pressure leakage, which will eventually cause product size deviation or surface defects.

Lubrication

Remember to lubricate the moving parts such as the plunger and injection cylinder regularly – this is particularly important for the smooth operation of the equipment.

Choosing the right grease and operating it according to the manufacturer’s recommended cycle can effectively reduce the wear of parts.

Don’t underestimate this step, it is directly related to the life of the equipment: if the lubrication is not in place, the parts may be damaged prematurely.

Before each operation, it is recommended that you confirm the lubrication record to avoid the risk of oil leakage and ensure production safety.

Cleaning

After each production task is completed, please immediately clean the metal debris and impurities remaining in the injection unit. Long-term accumulation of residues may cause nozzle clogging or plunger wear. It is recommended to use a soft brush to remove metal particles in the gap, and then wipe the surface oil with a non-woven cloth. In case of stubborn stains, special cleaning solvents can be used to assist in treatment.

Calibration

To ensure that the die casting machine can stably produce qualified parts, we need to calibrate the injection unit regularly. The calibration process includes three key steps:

Parameter detection

Use sensors to measure the actual injection speed, pressure and melt volume, and record the deviations against the equipment settings. For example, when the injection pressure fluctuates by more than ±5%, the casting may have pores or dimensional deviations.

Deviation correction

If abnormal parameters are detected:

- Check whether the hydraulic pump flow valve is loose (may cause unstable pressure)

- Test the seal for leakage (affects the melt volume accuracy)

- After re-entering the calibration parameters, it is necessary to test the injection 3 times for verification

Calibration cycle recommendation

Calibration must be performed every 5,000 molds in continuous production or after 7 days of downtime. The equipment log shows that the defect rate of machines that are not calibrated on time increases by an average of 37%.

Training

To ensure long-term stable operation of the equipment, the operator training must be solid and in place. You need to do the following:

- Fully master the key points of the equipment: Be familiar with the operating procedures, daily maintenance steps and safety regulations of the injection unit, which is the basis for efficient work.

- Actively discover hidden dangers: In actual operation, pay attention to observe equipment abnormalities (such as abnormal noise, oil pressure fluctuations), record and report problems in time.

- Continuous skill improvement: It is recommended to participate in training courses every quarter, focusing on learning the principles of hydraulic systems (such as oil circuit structure), fault diagnosis methods (such as error code interpretation) and calibration processes.

HAICHEN Proactive Support: Ensuring Injection Unit Reliability

At HAICHEN, we understand that maintenance extends beyond reactive repairs. Our after-sales service is design to prevent issues before they impact your production, especially for critical components like the injection unit.

- Data-Driven Preventive Maintenance

- Expert-Led On-Site Support

- Genuine Parts & Rapid Response

- Empowering Your Team

Data-Driven Preventive Maintenance

HAICHEN’s intelligent machines can track key injection unit parameters (e.g., pressure curves, cycle times). Our remote monitoring service analyzes this data trend to warn of potential wear, such as gradual plunger seal degradation or hydraulic pressure drift, allowing for planned intervention.

Expert-Led On-Site Support

We provide scheduled maintenance visits from certified HAICHEN engineers. They perform precise calibration, wear inspection, and alignment checks on the injection unit using specialized tools, ensuring it operates within original specifications.

Genuine Parts & Rapid Response

HAICHEN maintains a global supply chain for genuine spare parts, including injection cylinders, plungers, and seals. This guarantees perfect fit and performance, while our logistics network aims to minimize waiting time for critical components.

Empowering Your Team

We offer customized training programs focused on the daily inspection, lubrication, and basic troubleshooting of the injection unit. This knowledge transfer helps your operators identify early signs of issues and maintain optimal unit condition.

HAICHEN: Die Casting Machine Manufacturer

As a professional manufacturer in the field of die casting machines, HAICHEN is always committed to providing customers with stable and reliable equipment solutions.

Our products are manufactured with cutting-edge technology and can withstand the long-term test of industrial environments. Whether you need a cold chamber model to process aluminum alloy parts or a hot chamber model to cope with zinc alloy production, we can provide equipment options that match your production needs.

After purchase, you will receive continuous technical support, timely spare parts supply and operation training services to ensure the maximum value of your equipment investment.

In conclusion, aking good care of the Injection Unit is key to reliable production and less machine stoppage. Stick to a planned maintenance routine that covers checking parts, adding grease/oil, cleaning away buildup, making sure settings are accurate, and training your staff. This consistent care helps the Injection Unit last longer and keeps your die casting line producing steadily.