Intelligent fault diagnosis of a plunger rod involves using advanced sensors and data analytics to monitor its performance, detect anomalies, and predict potential failures, ensuring timely maintenance and minimizing downtime.

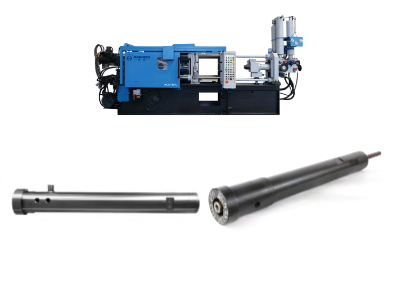

In the die-casting industry, the plunger rod is a critical component of the injection system. Responsible for injecting molten metal into the mold cavity with high precision and consistency.

Any malfunction or failure of the plunger rod can lead to production delays, defective parts, and increased maintenance costs.

Therefore, intelligent fault diagnosis of the plunger rod is essential for maintaining high production efficiency and product quality.

Importance of Intelligent Fault Diagnosis

Intelligent fault diagnosis leverages advanced technologies such as sensors, data analytics, and machine learning to monitor the performance of the plunger rod in real-time. By analyzing data from various sensors installed on the plunger rod and the die-casting machine, potential issues can be detected early, allowing for proactive maintenance and minimizing downtime. This not only improves the reliability of the production process but also extends the lifespan of the plunger rod by addressing issues before they escalate.

For manufacturers producing high-precision components like fracture splitting connecting rods, where dimensional accuracy and structural integrity are critical, such intelligent systems are indispensable. Even minor deviations in the plunger rod’s performance can affect the quality of such precision components.

Common Faults and Their Indicators

- Wear and Tear

- Leakage

- Misalignment

Wear and Tear

The die-casting process exposes plunger rods to extreme temperatures and pressures, gradually wearing them down through continuous operation. Indicators of wear include increased injection pressure, inconsistent shot sizes, and visible damage on the rod surface. Sensors that measure pressure, temperature, and displacement can help detect these issues early.

Leakage

Leakage of molten metal around the plunger rod can lead to defects in the final product and potential damage to the machine. Indicators of leakage include irregularities in the injection pressure profile and visual signs of molten metal seepage. Intelligent systems can use pressure sensors and thermal imaging to detect and locate leaks.

Misalignment

Misalignment of the plunger rod can cause uneven wear and poor injection performance. Displacement sensors and vibration analysis detect misalignment issues. Advanced diagnostic tools monitor and analyze the resulting vibration increases and injection speed inconsistencies.

Intelligent Diagnosis Techniques

- Sensor Integration

- Data Analytics and Machine Learning

- Remote Monitoring and Diagnostics

Sensor Integration

Modern die-casting machines incorporate multiple sensors to track critical parameters including pressure, temperature, displacement and vibration. These sensors generate real-time data for anomaly detection and fault prevention analysis. For example, pressure sensors can detect sudden changes in injection pressure, while vibration sensors can identify misalignment issues.

Data Analytics and Machine Learning

By collecting and analyzing large amounts of data from the sensors, machine learning algorithms can identify patterns and trends that indicate potential faults. Data scientists develop predictive maintenance models that forecast service requirements, enabling proactive interventions to prevent unplanned downtime.

Remote Monitoring and Diagnostics

Remote monitoring systems allow operators to access real-time data and diagnostic reports from anywhere, enabling quick response to potential issues. Cloud-based platforms can store historical data and provide advanced analytics, making it easier to identify and address recurring problems.

Operational Framework for Implementing Intelligent Diagnosis

Building an intelligent diagnosis system for the plunger rod requires a structured operational framework to ensure closed-loop management of monitoring, analysis, and action.

- Data Collection and Real-time Monitoring

- Data Analysis and Fault Alert

- Maintenance Decision and Action Tracking

Data Collection and Real-time Monitoring

Deploy high-precision sensors at critical points on and around the plunger to continuously collect pressure, displacement, temperature, and vibration signals. Data is transmitted in real-time via industrial networks to an edge computing unit or central controller to establish a continuous performance baseline.

Data Analysis and Fault Alert

Machine learning algorithms analyze the real-time data stream to identify abnormal patterns that deviate from the baseline. The system correlates anomalies to specific fault types (e.g., wear, leakage) and automatically generates tiered alerts (e.g., notice, warning, alarm) indicating the potential risk level.

Maintenance Decision and Action Tracking

Based on the alerts, the system recommends specific maintenance actions (e.g., check seals, calibrate alignment). All alerts and subsequent maintenance actions are logged, creating a traceable fault knowledge base used to refine algorithm models and maintenance schedules.

HAICHEN: Advancing Intelligent Die-Casting Solutions

At HAICHEN, we understand the critical role of plunger rod performance in ensuring high-quality die-casting production. Our advanced die-casting machines incorporate state-of-the-art intelligent diagnostic systems specifically designed to monitor and maintain optimal plunger rod performance.

Real-World Application in Fracture Splitting Connecting Rods Production

HAICHEN’s intelligent systems have demonstrated exceptional performance in manufacturing high-precision components such as fracture splitting connecting rods. These components require extremely tight tolerances and perfect filling conditions, which can only be achieved through consistent plunger rod performance. Our monitoring systems ensure that any potential issues affecting the quality of these critical components are detected and addressed proactively.

Why Choose HAICHEN?

- Advanced Technology: Our die-casting machines are equipped with state-of-the-art sensors and intelligent diagnostic systems that provide real-time monitoring and analysis of the plunger rod’s performance.

- Predictive Maintenance: By leveraging data analytics and machine learning, our machines can predict potential faults and recommend timely maintenance, reducing downtime and maintenance costs.

- Comprehensive Support: We offer comprehensive after-sales support, including technical assistance, maintenance services, and training, ensuring that our customers can fully benefit from our intelligent diagnostic systems.

- Customized Solutions: We understand that each customer’s needs are unique. Our machines can be customized to meet specific production requirements, ensuring optimal performance and efficiency.

Intelligent fault diagnosis of the plunger rod is a crucial aspect of modern die-casting operations. By integrating advanced sensors, data analytics, and machine learning, manufacturers can detect and address potential issues early, ensuring high production efficiency and product quality.

HAICHEN’s commitment to technological innovation ensures that our customers remain at the forefront of die-casting excellence, particularly in demanding applications such as the production of fracture splitting connecting rods and other precision components.