During the die-casting process, the high-temperature and high-pressure operation of molten aluminum poses certain risks:

- Aluminum safety risks

- Hidden dangers existing in the machine aspect

- The risks caused by management negligence

- Occupational Health Effects

- Safety Standards

During the die-casting process, the high-temperature and high-pressure operation of molten aluminum poses certain risks, such as leakage and explosion of molten metal.

Therefore, strict safety measures need to be taken, such as regular equipment maintenance, providing personal protective equipment, and ensuring that operators receive professional training.

The main die casting aluminum material safety risks

- Transportation and dumping

- Improper equipment maintenance

- Residual aluminium treatment

Explosion in contact with water at high temperature molten aluminum has a temperature of up to 660-750°C.

And if it encounters water or humidity, it will instantly generate a large amount of steam and cause an explosion.

Transportation and dumping

When the molten aluminum ladle is damp or encounters rain, it is prone to explosion during the dumping process.

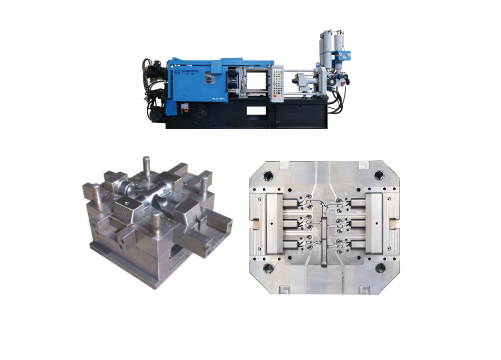

Improper equipment maintenance

Molten aluminum contacts molds, launders, etc. before they dry completely, or a leaking cooling system triggers an explosion.

Residual aluminium treatment

In addition, when discharging molten aluminum to an unpreheated residual aluminium tank.

Then,it may cause an explosion due to residual moisture.

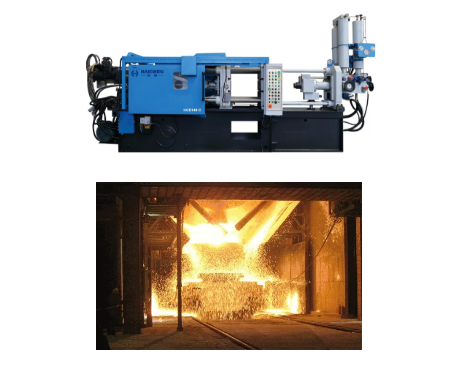

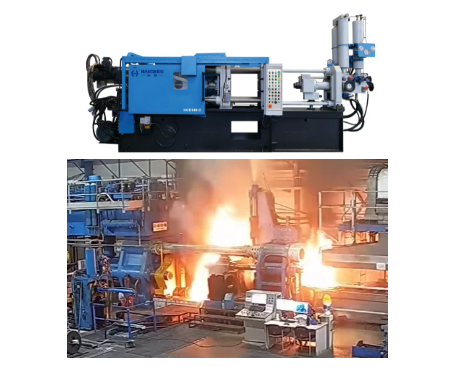

Hidden dangers existing in the machine aspect

- High Pressure Injection Molding Risks

- Equipment failure

- Hidden dangers of automation equipment

High Pressure Injection Molding Risks

Die casting machines operate at high pressures (typically over 10,000 psi) and high speeds (16-80 m/s).

And splashing of molten metal can cause burns or mechanical shock injuries.

Equipment failure

Crane wire rope breakage, forklift loss of control or pressure vessel explosion, etc., may lead to liquid aluminum leakage or casualties.

Hidden dangers of automation equipment

Failure of six-axis robot or hydraulic system may cause mechanical injuries such as pinching and crushing.

Chemical and dust hazards

- Toxic gas leakage

- Aluminum dust explosion

Toxic gas leakage

Toxic gases such as carbon monoxide and hydrogen arsenide can escape during the smelting process.

Without monitoring and alarm devices, these gases may quickly cause poisoning.

Aluminum dust explosion

If workers do not clean the aluminum chips from finishing in time, open flames or static electricity can trigger a dust explosion actually.

Negligence in operation and management

Human error

First,failure to wear protective equipment, failure to preheat molds, or illegal operation of equipment may directly lead to accidents.

Inadequate emergency measures

For example, the lack of interlocking systems such as quick shut-off valves and level alarms can magnify the consequences of accidents.

Occupational Health Effects

- Acute Hazards Skin & Eye Damage

- Acute poisoning

- Neurological damage

- Bone problems

- Lung diseases

Acute Hazards Skin & Eye Damage

In fact,splashes of molten aluminum can cause severe burns and eye burns.

Acute poisoning

Inhalation of high concentrations of CO or fluoride may cause symptoms such as headache and coma.

Neurological damage

Long-term exposure to aluminum may lead to memory loss, cognitive decline.

And is associated with Alzheimer’s disease risk.

Bone problems

As a result of prolonged exposure,aluminum deposits in bones can displace calcium, leading to an increased risk of osteoporosis and fractures.

Lung diseases

In particular,aluminum pneumoconiosis and pulmonary fibrosis are common occupational conditions for aluminum die casting workers.

Safety Standards and Protective Measures in the Aluminum Die Casting

Industry Process & Equipment Specifications

Explosion-proof design

Workers must keep smelting furnaces, launders, and other areas dry.

They should install emergency discharge valves and quick shut-off devices eventually.

Monitoring and interlocking

To ensure operational safety,workers must install pressure and flow monitoring devices on the mold cooling water system and interlock them with safety facilities.

Operator protection

Training and qualification:Operators need to be certified to work and be familiar with equipment performance and emergency plans.

Personal protective equipment: Mandatory use of heat-resistant gloves, protective masks, earplugs, etc.

Management Cleaning & Ventilation

To maintain a safe working environment,regularly clean aluminum chips, keep the workplace tidy.

And equipped with ventilation systems to reduce dust concentration.

Equipment maintenance

Then,regularly inspect the hydraulic system of the die-casting machine, wire rope and other key components to prevent failures.

Waste Gas Treatment

Water spraying, activated carbon adsorption, bag dust removal and other technologies are used to purify smoke and harmful gases.

The exhaust gas emission must meet the limits of particulate matter ≤ 20mg/m³ and SO₂≤100mg/m³.

Solid waste recycling

Leftovers, gates, etc. can be melted and recycled to reduce resource waste.

Aluminum slag needs to be separated by magnetic separation of metal aluminum.

And hazardous waste needs to be stored separately.

Wastewater control

Cooling water and domestic sewage need to be pretreated and included in the municipal pipe network, and direct discharge is prohibited.

Die casting aluminum safe emergency response mechanism

Leakage Handling

In the event of a molten aluminum leak, emergency cooling water should be activated immediately and personnel should be evacuated to a safe area.

Fire prevention and control

Open flames are prohibited in the work area, and dry powder fire extinguishers and automatic sprinkler systems are configured.