Ladle cup die casting key features includes material, high temperature, corrossion resistance, sealing and airtightness and so on.

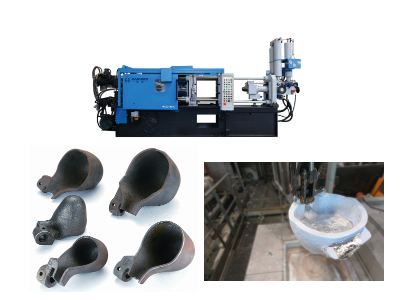

The Ladle Cup (also known as the pouring cup) is a metal container mounted on the end of the ladle handle, used to hold and deliver molten metal to the shot sleeve or directly pour it into the mold during the cold chamber die casting or hot chamber die casting process. It is a key component to achieve “fast, stable, low temperature loss” metal pouring.

We will analyze the key features of ladle cup in die casting with

- Material and high temperature resistance

- Corrosion resistance

- Design optimization

- Durability and maintenance-free

- Wide range of applications

- Various weight specifications

The main features of the die-casting machine ladle cup include:

Material and high temperature resistance

The die-casting machine spoon is usually made of high melting point materials. Such as ceramics or ductile iron, with a high melting point (such as the melting point of the ceramic spoon is 1860℃±10℃). And excellent thermal shock resistance (such as To > 1000℃). It can withstand high temperature environments.

Aluminum Alloy Die Casting

(Melt Temperature Approximately 660°C)

- Main Structure: H13 or Fastcool55 (Thermal Fatigue + High Thermal Conductivity)

- Bottom Lining: E-SY2000 Ceramic Castable (Resistant to 1450°C)

- Surface Coating: Refractory ceramic or aluminum oxide coating to prevent welding and corrosion

Magnesium Alloy Die Casting

(Melt Temperature Approximately 650°C)

- Use H13 or 8407 for a balance of high-temperature strength and toughness.

- For longer life, choose Fastcool55 to improve thermal conductivity and reduce welding risks.

Zinc Alloy Die Casting

(Melt Temperature Approximately 420°C)

- Conventional heat-resistant steels (H11 and H13) are sufficient; if cost is a concern, ordinary cast steel or ductile iron can be used.

High-temperature Alloy Casting

(e.g., copper-based, titanium alloys)

- For higher temperature resistance: Stellite6B (Resistant to 870°C) or cobalt-based alloys.

- A refractory ceramic lining can be used on the bottom to prevent high-temperature corrosion.

Corrosion resistance

The spoon material must have good corrosion resistance to adapt to the corrosive environment of high temperature solutions such as aluminum water and zinc alloy.

Die casting machine ladles must be preheated before use. Recoated regularly during operation to prevent welding, erosion, and high-temperature heat loss.

Surface Protective Layer (Coating)

- Ceramic Thermal Spray (Al₂O₃-MgO, SiC, ZrO₂)

High melting point and high hardness, it forms a dense layer above 800°C, significantly reducing metal penetration and adhesion. - Nitriding/Carburizing

Produces a hardened layer on the steel surface, improving wear and corrosion resistance. Commonly used for molds and hopper shells. - Metallic Plating (Chrome, Nickel)

Forms a dense metal oxide film, preventing molten metal from directly contacting the substrate. - Refractory Castable Lining (High-Alumina Bricks, Cast Refractory Castables)

Using low-moisture, uniformly sized Al₂O₃-MgO significantly improves corrosion and penetration resistance.

Design and Process Measures

- Cold Chamber Structure: Separates the molten metal from the injection mechanism, preventing high-temperature metal from directly corroding critical components such as the injection piston.

- Separate Hopper: A removable hopper facilitates liner replacement and corrosion inspection.

- Temperature Control: Maintains the hopper temperature slightly below the liquidus temperature of the molten metal to reduce the rate of chemical penetration of the metal into the hopper.

- Flow Path Design: Prevents metal from remaining in the hopper for extended periods of time, minimizing localized high-temperature corrosion.

Design optimization

Modern spoon designs focus on reducing the chance of oxide scale entering the aluminum liquid, such as using a closed small opening design to improve the defective rate of die-casting parts.

Optimization Goals

- Minimize heat loss → Improve metal temperature retention.

- Reduce temperature drop during the pouring process → Prevent thermal cracking and shrinkage.

- Reduce pouring time → Improve production efficiency.

- Reduce turbulence and inclusion generation → Improve casting surface quality.

- Reduce wear on machinery and molds → Extend equipment life.

Cup Volume

Take 1.1 x shot weight (kg) as a benchmark. This value can be refined within ±5% to balance heat retention and metal overflow risk.

Inclined Speed Curve

A two-stage method (a fast first half (v₁≈30%-40% of maximum speed), and a second half (v₂≈10%-20% of lower speed) maintains a stable liquid level while shortening pouring time.

Pouring Flow Rate

Maintain in the laminar flow region (Re < 2000). The specific value depends on the alloy viscosity and cup opening diameter, with a typical range of 30–45 m/s. Excessively high values will cause spray marks and surface defects.

Cup Insulation

Adding a high-temperature-resistant insulation layer (5–10 mm thick) to the outer wall of the cup can reduce heat loss by approximately 10–15%.

Haichen’s ladles are precision-engineered to optimize the molten metal transfer process in die casting. Manufactured from high-grade refractory and steel materials, Haichen ladles are designed for exceptional thermal resistance and structural integrity. It includes a balanced, ergonomic design for operator safety and control, and specialized coatings that minimize heat loss and metal adherence. This ensures accurate, consistent dosing, reduces temperature drop of the aluminum, and minimizes slag inclusion. By enhancing transfer efficiency and metal quality, use Haichen ladles.

Durability and maintenance-free

- Ceramic spoons usually do not need to be coated with coating agents. Moreover, it has a long service life (generally 6-12 months), which reduces the frequency of replacement and reduces maintenance costs.

- Dtemperature-resistant insulation layer (5–10 mm thick) to the outer wall of the cup can reduce heat loss by approximately 10–15%.

Wide range of applications

Die-casting machine spoons are suitable for a variety of metal solutions.

Such as aluminum water, copper water, zinc alloy water, etc., They widely use in aluminum, zinc, iron, copper and other die-casting processes.

Various weight specifications

The spoons are available in a variety of specifications, ranging from 0.3kg to 25kg, to meet different die-casting needs.

The main features of the die-casting machine spoon are concentrated in high temperature resistance, corrosion resistance, sealing, durability and design optimization. These characteristics make it an indispensable and important accessory in the die-casting process.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.