The making process of zinc alloy medal includes mold design, mold making, die-casting machine injection, and finishing.

Initially, zinc alloy of high quality is first prepared and melted in a controlled atmosphere.

The form of medals is achieved through high – pressure injection of molten alloy into precision – crafted molds.

Medals are removed from the molds after they have cooled and solidified.

They go through polishing, plating, and engraving to further improve their visual appeal as well as their durability.

The medals are then packed in a suitable container after a quality check to confirm that they are free from defects.

In this article, I will explain how high quality zinc alloy medals are created with die casting techniques. And this is the making process of zinc alloy medal:

Creating A Design and Preparing a Mold

A medal begins with a design. Metal works and jewelers prepare all images, texts, and other intricacies of the medal. After the design, a mold is manufactured which is an exact copy of the medal. The mold is made out of high-end materials such as metal to ensure quality and precision during the casting process.

Die CastingMetal Melting

We select zinc alloy for being robust and corrosion resistant. During the die casting process, we place the alloy into a furnace and heat it until it turns to liquid.

It is very important that the metal is at the right temperature before being injected, otherwise, it will not flow into the mold cavities as desired. During this time, the temperature is strictly regulated, because metal requires a specific heating point. Overheating could ruin the end product.

After fully molten, the alloy is moved to a die-casting machine where the next stage of the process begins.

Die Casting

Casting of the medal begins with having liquid zinc alloy along with the mold. In hot chamber die casting, the mold is poured with hot metal under extreme pressure. The intricacy of the design ensures that all details of the medal are included within the medal, which makes it look stunning.

Cooling and Ejection

Once the metal has been poured into the mold, it goes undergoes the cooling phase along with achieving medal solidification.

Without a doubt striking cooling systems are integrated with traditional CNC machines to drastically bring down the cooling time

During this stage the medal and mold go through the stage of optimally controlled cooling to solidify. It is essential for the mediator in order to assure that all details of the shape are kept intact along with smooth edges. Because of this method, none of the cracks or warping are inflicted on the medal.

Once the medal has fully solidified, we proceed with the ejection process. The medal is carefully ejected from the mold using automated systems designed to handle delicate parts without causing damage. This ensures that the medal is ready for further processing, such as finishing touches or quality inspection, with minimal risk of defects.

Finishing and Polishing

We accomplish the polishing of the medals’ surface after deflashing them so that any rough edges and inaccuracies can be removed. We also ensure that the medals have a smooth and shiny finish, which makes them far more appealing.

Plating and Coloring

In addition to improving the looks of the medal, the strength of the medal is improved through staking of the other metals. This includes gold, copper, and silver metals. Thus they turn out looking far more attractive than before as they are now being colored through painting and enameling.

Quality Control

Each medal goes through numerous steps of quality check so that their design, finishing, and materials used are of the right required standards. Any medal that does not meet the quality requirements of bare minimum standards is set aside and either reworked or disposed of.

Precision zinc alloy medals making with Haichen die casting machine

For the manufacture of Zinc Alloy Medals, high-precision die casting machine is essential to make good details and quality uniform.

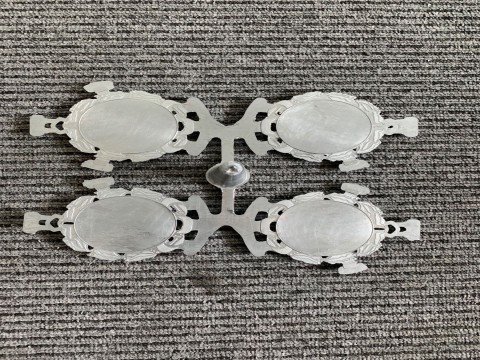

In the process of manufacturing the medals, were employed HCD50-H hot chamber die casting machine from Haichen by its ability to replicate of complex geometrical designs (profiles as heavy 3D impression, edge of badge, quantity of cavities per mould), with dimensional accuracy up to ± 0.03 mm.

An example of a medal manufacturing in Thailand:

One day in 2023, a medal factory owner in Thailand called us, we were asked by him to change the the mould and die casting machine for his commemorative medal for him. We had supplied him with the die-castingmachine at that time as follows;

- 0% porosity on key surfaces (guaranteed by integrated vacuum system)

- Mirror polished mold cavity saves 40% polishing time

- High speed mass production cycle of only 12 seconds per medal

Haichen machines accept Zamak 3/5, 2/5, balancing cost efficiency and detail fidelity for medal applications.

Hot chamber die casting is one type of making process of zinc alloy medal. This allows for detailed designs to be incorporated while still making it highly durable, and visually appealing.

Using advanced die casting technologies, award winning medals for diverse commemorative and sporting events can now be easily manufactured.