The price of aluminium radiators die casting machines in the Chinese market, the 300-ton model is approximately 50,000 US dollars, the 800-ton model reaches 100,000 to 200,000 US dollars,and the 1,600-ton model exceeds 300,000 US dollars.

The price of aluminium radiators die casting machines in China varies depending on the model, tonnage, brand, and configuration.

Generally speaking, the price range of aluminium radiators cold chamber die casting machines is positively correlated with the tonnage of the equipment.

The price factors of aluminum radiator die-casting machines

Purchase cost

Cold chamber die casting machines are suitable for small-scale, low-cost production with a relatively low initial purchase cost.

However, the mold cost of aluminum die-casting molding is higher.

Especially when it is necessary to make radiators with complex shapes,the mold cost will further increase.

In addition, the price of aluminum is higher, which also affects the overall purchase cost.

Maintenance costs

Aluminum die-cast radiators require certain expertise and skills in installation and maintenance.

And improper installation may lead to poor heat dissipation or water leakage, which may increase additional maintenance costs.

Haichen Aluminium Radiators Die Casting Machine Price

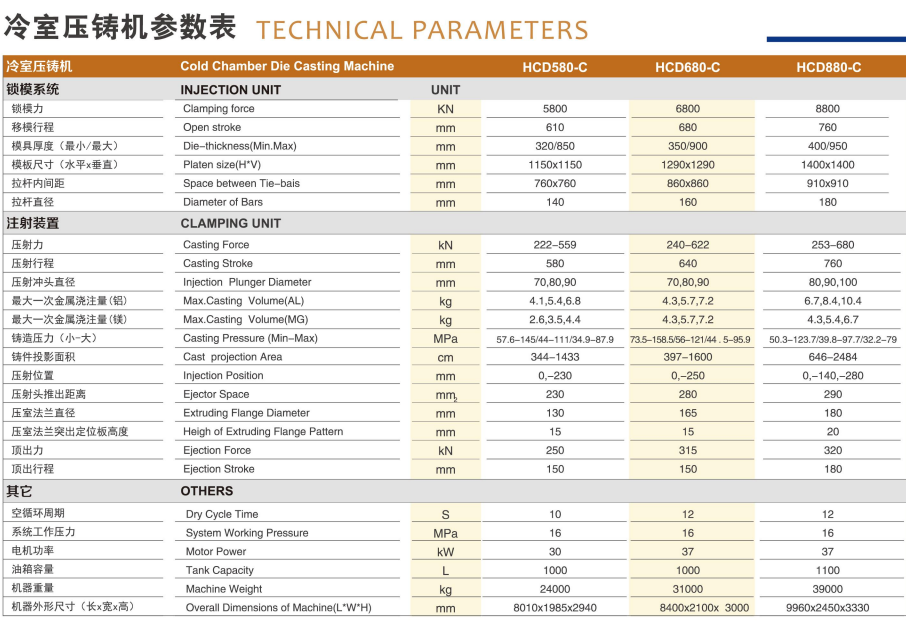

The price of Haichen 880 ton aluminum radiator cold chamber die casting machine:

Single set price: $147,600.00

Two sets and more: $146,600.00

If you need more information, please feel free to contact us at any time.

The influence of different configurations on the price of die-casting machines

- Tonnage of die-casting machine

- Degree of automation

- Raw material and energy costs

Tonnage of die-casting machine

The larger the tonnage of the die-casting machine, the higher its price.

This depends on the size, weight and output of the radiator,because these determine the size of the mold.

The price of die-casting machines with a capacity of over 1,000 tons rises in tandem with the increase in clamping force.

Degree of automation

The higher the degree of automation, the higher the price of the die-casting machine.

The die-casting production line equipped with automated equipment involves a series of auxiliary machines, such as mechanical arms, etc., and the cost is relatively high.

The advantage of equipping these devices is that it can enhance production efficiency and, to a certain extent, reduce labor costs.

Raw material and energy costs

Fluctuations in the prices of metal raw materials will also have an impact on the cost of die-casting machines.

This will affect the cost price of some die-casting machine parts, and most importantly, it may have an impact on the production cost of molds.

Main manufacturers of radiator die-casting machines in China

- Lk Technology

- Yi Zu Mi

- Haitian Metal

Lk Technology

Lk IMPRESS & D-Series cold chamber die casting machines, AVIS & CLASSIC hot chamber die casting machines, VISION hot chamber die casting machines, and IMPRESS-M series magnesium alloy die casting machines.

The clamping force range is from 1,300 tons to 12,000 tons (for some models, it is 16,000 tons).

The products are widely applied in fields such as automobiles, 3C products, aerospace, etc.

Yi Zu Mi

The main products are the LEAP series super-large die-casting machines, the H II series die-casting machines, the HM high-performance hot chamber die-casting machines, and the DM-H series heavy-duty die-casting machines.

The clamping force range is 4,500-9,000 tons (LEAP series), which is dedicated to the special mechanical equipment for compression molding.

Haitian Metal

The main products are HDC series cold chamber die casting machines and HMG series die casting machines.

The clamping force range is 180 to 8,800 tons.

The market and price trends of aluminum radiator die-casting machines

- Market supply and demand situation

- Price trend

Market supply and demand situation

The global market for aluminum radiator die-casting machines is projected to reach 6.296 billion US dollars in 2024 and grow to 9.277 billion US dollars by 2033, with a compound annual growth rate (CAGR) of 4.4%.

As one of the world’s major consumer markets, the Chinese market is expected to lead the market by 2032.

Price trend

The global aluminum die-casting machinery market is projected to reach 6.296 billion US dollars in 2024 and grow to 9.277 billion US dollars by 2033, with a compound annual growth rate of 4.4% projected from 2025 to 2033.

This indicates that the price of aluminum die-cast radiators will gradually rise along with the growth of market demand.

The impact of technological iteration of die-casting machines on prices

Firstly, intelligent transformation, by introducing automated control systems, artificial intelligence and big data analysis,

Has achieved real-time monitoring and optimization of the production process, enhancing production efficiency and product quality, while reducing labor costs and downtime.

Secondly, the application of energy-saving technologies has significantly reduced the energy consumption of die-casting machines.

Servo systems and frequency converters and other technologies achieve automatic regulation of pressure and flow by adjusting the rotational speed of the oil pump motor, reducing energy loss caused by high-pressure overflow and thus achieving energy-saving effects.

The intelligent and energy-saving technologies of die-casting machines not only effectively reduce production costs.

But also enhance the market competitiveness and sustainable development capabilities of enterprises.