Quick Die Change System (Quick Die Change System) in the die casting process application is mainly focused on the rapid replacement and installation of the mold to improve production efficiency and flexibility.

Traditional mould handling systems require operators to physically enter the press, manually loosening and tightening bolts on the clamping device, which may pose risks to personnel. Furthermore, the resulting downtime wastes valuable production time, adversely affecting both product quality and manufacturing efficiency. Consequently, automated rapid Quick Die Change System have become essential.

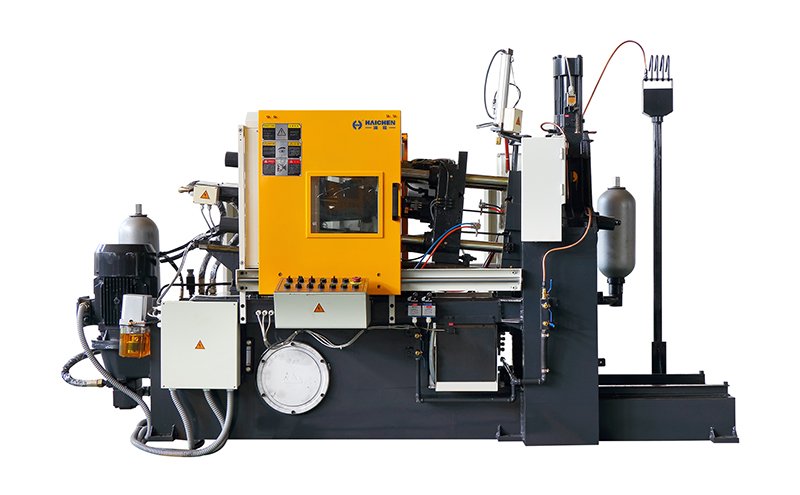

Haichen has developed and integrated a product designed for rapid die change in die-casting machines, rapid die change in stamping presses, and rapid die change within the die-casting industry.

Process of Quick Die Change Systems for Die Casting

The process of Quick Die Change (QDC) Systems for die casting involves several key steps and components designed to streamline die changes, reduce downtime, and enhance overall productivity.

Here is a detailed overview of the process:

- Preparation of Quick Die Change System

- Die Removal of Quick Die Change System

- Die Installation

- System Calibration and Testing

- Production Resumption

- Documentation and Maintenance

Preparation of Quick Die Change System

Die Preparation: Ensure the die is clean, properly maintained, and ready for installation. This includes checking for any wear and tear, ensuring all components are in place, and applying necessary lubricants.

QDC System Check: Verify that the QDC system components (clamps, hydraulic or pneumatic systems, alignment tools, etc.) are functioning correctly and are in good condition.

Die Removal of Quick Die Change System

Machine Shutdown: Safely shut down the die casting machine and ensure it is in a safe state for die change.

Clamp Release: Use the QDC system to release the clamps holding the current die in place.

Die Extraction: Carefully remove the die from the machine using overhead cranes or other lifting equipment. Ensure that lift and move the die is securely to a designated storage or maintenance area.

Die Installation

Alignment: Position the new die in the machine using alignment tools provided by the QDC system. Proper alignment is crucial for ensuring the die operates correctly and produces quality castings.

Clamping: Use the QDC system to securely clamp the new die in place. The system should provide uniform clamping force to ensure the die is held firmly and evenly.

Connection: Reconnect any necessary hoses, cables, or other connections required for the die to function, such as cooling lines or ejector systems.

System Calibration and Testing

Calibration: Calibrate the machine settings to match the specifications of the new die. This includes adjusting the clamping force, injection pressure, and other parameters.

Test Run: Conduct a test run to ensure the die is properly installed and the machine is functioning correctly. Inspectors should check for any leaks, misalignments, or other issues that need to be addressed.

Production Resumption

Startup: Once the test run is successful and all parameters are verified, resume production. Monitor the initial castings to ensure they meet quality standards.

Continuous Monitoring: Continuously monitor the die and machine performance during production to quickly identify and address any issues that may arise.

Documentation and Maintenance

Record Keeping: Document the die change process, including any adjustments made and the results of the test run. This helps in maintaining a history for future reference and troubleshooting.

Maintenance: Regularly maintain the QDC system and dies to ensure they remain in optimal condition. This includes routine inspections, lubrication, and replacement of worn-out components.

Benefits of QDC Systems in Die Casting

- Reduced Downtime

- Increased Flexibility

- Improved Safety

- Cost Saving

- Consistent Product Quality

Reduced Downtime

Streamlines the die change process, significantly reducing the time between production runs.

Increased Flexibility

Allows for more frequent changeovers and shorter production runs, enabling better adaptation to market demands.

Improved Safety

Minimizes manual handling of heavy dies, reducing the risk of accidents.

Cost Savings

Lower labor costs, reduced downtime, and improved efficiency lead to significant long-term savings.

Consistent Product Quality

Precise and repeatable die changes help maintain consistent product quality.

Haichen die casting machine supplier

Our Haichen machines incorporate open-source quick mold change options in their designs, providing robust technical support for the production of a wide variety of molded products.

Haichen is a well-known supplier of die casting machines, offering a range of equipment designed for various die casting applications. We mainly supply cold chamber and hot chamber die casting machines and auxiliary equipments.

We typically provide comprehensive product catalogs for more detailed information, technical specifications, and customer service contacts to assist with inquiries and orders.