Properties of cast aluminum includes lightweight and high strength, good casting performance, corrosion resistance, and others.

The core of cast aluminum alloys’ excellent casting properties lies in their high fluidity, resistance to hot cracking, low melting point, and process adaptability. This makes them ideal materials for applications in the automotive, aerospace, and electronics sectors. However, the high shrinkage and composition sensitivity of cast aluminum alloys require mitigation through melting control, mold optimization, and alloy design (such as adding silicon to enhance fluidity).

The varying properties of various alloys necessitate the selection and setting of process parameters based on specific application requirements (e.g., complexity, strength, and environmental requirements).

Cast aluminum is an important material widely uses in automobiles, aerospace, home appliances and other fields.

- Lightweight and high strength

- Good casting performance

- Corrosion resistance

- Thermal conductivity

- Mechanical properties

- Properties of cast aluminum Limitations

Lightweight and high strength

- Low Density

- Weight Reduction Advantages

- Strength-to-Weight Ratio

- Tensile Strength and Toughness

Cast aluminum has an excellent strength-to-weight ratio, which gives it significant advantages in reducing weight and improving fuel efficiency. For example, aluminum has a density of about one-third that of iron, but its strength is close to that of steel. So it widely uses in automobile manufacturing.

Low Density

Aluminum has a density of approximately 2.7 g/cm³, only one-third that of steel. This makes cast aluminum alloy parts significantly lighter, making them suitable for weight-sensitive applications such as automotive and aerospace to improve fuel efficiency or payload capacity.

Weight Reduction Advantages

In automotive manufacturing, lightweight design reduces energy consumption and improves safety; in aerospace, every ounce of weight saved counts.

Strength-to-Weight Ratio

Despite their low density, cast aluminum alloys can achieve strength approaching that of wrought alloys through alloying (such as the addition of elements like Si, Cu, and Mg) and heat treatment (such as hot isostatic pressing).

Tensile Strength and Toughness

- Optimizing alloy composition and processing can enable cast aluminum alloys to achieve moderate to high strength while maintaining good elasticity, making them suitable for complex structural parts.

- Cryogenic Performance: Aluminum maintains high strength and toughness even at extremely low temperatures.

Good casting performance

- Excellent Filling Capacity

- Hot Tearing Resistance

- Low Melting Point and Rapid Solidification

- Low Gas Solubility and Airtightness

Cast aluminum has high fluidity, low melting point and short casting cycle, which enables the manufacture of parts with complex shapes during the casting process and is not prone to thermal cracking.

Excellent Filling Capacity

- Fluidity refers to the ability of a molten alloy to fill a mold, directly impacting the quality of complex castings. Aluminum-silicon eutectic alloys (such as ADC12 and Alloy 360) exhibit the best fluidity, which can be optimized by adjusting pouring temperature and pressure.

- In actual production, increasing pouring temperature and enhancing the melting process (refining and slag removal) can significantly enhance fluidity, meeting the casting requirements of thin-walled parts and delicate structures.

Hot Tearing Resistance

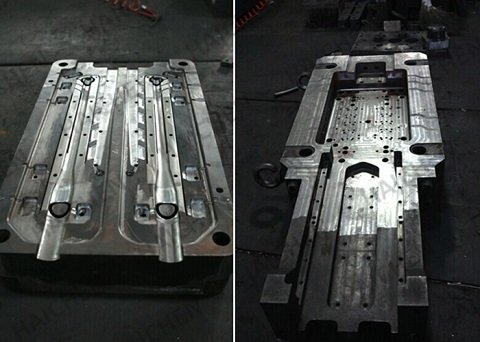

Aluminum alloys experience volumetric shrinkage of 3.5%–8.5% during solidification, which can easily lead to hot cracking. Good castability requires resistance to hot cracking, which is particularly crucial in high-production processes such as die casting and high-pressure die casting machine.

Some alloys, such as cerium-containing aluminum alloys, can improve their hot cracking resistance through composition optimization. However, aluminum-zinc-magnesium (Al-Zn-Mg) alloys are susceptible to hot cracking defects due to their high shrinkage, requiring strict process control.

Low Melting Point and Rapid Solidification

- Aluminum alloys have low melting points (e.g., 360 alloy, approximately 635°C), which reduces energy consumption and accelerates solidification, making them suitable for efficient production.

- Rapid solidification reduces the risk of segregation and improves casting uniformity, making it particularly suitable for thin-walled parts and complex geometries.

Low Gas Solubility and Airtightness

- Aluminum alloys have low gas solubility, except for hydrogen. However, excessive hydrogen content can easily form pinholes, impairing airtightness and mechanical properties. Hydrogen can be effectively controlled through flux melting and in-line degassing (such as AdTech technology).

- After optimizing the melting process, castings can meet high-pressure sealing requirements and are suitable for fluid sealing components such as valve bodies and pump casings.

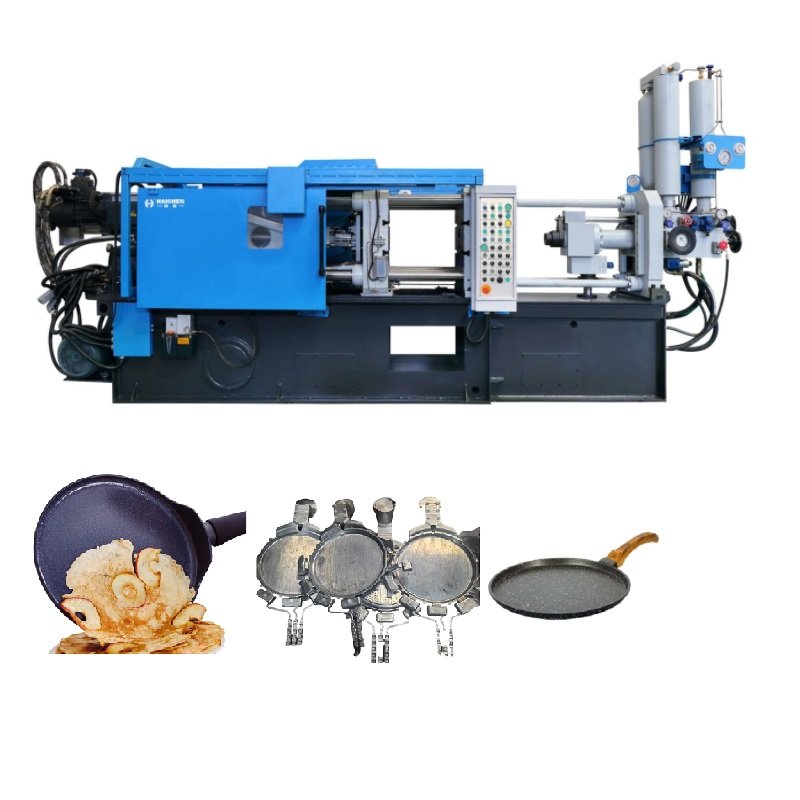

Haichen cast aluminium performance case

For example, Haichen aluminium die cast frying pans. Our client utilises our high pressure cold chamber die-casting machines to produce the pan bodies. By selecting aluminium alloys with excellent fluidity and employing high-pressure die-casting techniques, they rapidly form the complex curved and thin-walled structures of the pan body. This ensures even heat distribution and delivers high structural strength, meeting the durability requirements for daily cooking. The finished frying pans with no bubbles after 400℃.

Aluminium pan handles: For handle components, the client utilises Haichen equipment for die-casting. They employ an aluminium alloy with high strength and low thermal conductivity. Handles produced this way remain cool to the touch during cooking, while their excellent die-casting formability ensures ergonomic design, comfortable grip, and secure attachment.

These examples demonstrate how Haichen die-casting machines empower clients to leverage the inherent properties of cast aluminium alloys – including fluidity, strength, thermal conductivity, and corrosion resistance – tailored to each product’s core requirements. This approach achieves efficient, high-quality production.

Corrosion resistance

- Basic Corrosion Resistance Mechanism

- The Necessity of Surface Treatment

A protective aluminum oxide film is formed on the surface of cast aluminum, which makes it have good corrosion resistance and is suitable for a variety of environmental conditions.

Basic Corrosion Resistance Mechanism

When exposed to air, aluminum instantly forms a dense protective layer of aluminum oxide (Al₂O₃), which is the core mechanism of its corrosion resistance. This layer resists attack by air, water, and a variety of chemicals, making cast aluminum alloys suitable for outdoor and marine environments.

The Necessity of Surface Treatment

- Anodizing: The most effective protective method, significantly improving corrosion resistance by artificially thickening the oxide layer, is particularly suitable for harsh environments.

- Other coatings: such as powder coating, electrophoretic coating (E-Coating), and Teflon coating, can fill microscopic defects and provide an additional barrier.

- Limitations of Untreated Parts: Original castings may fail in humid or salty environments. Surface treatment is key to ensuring long-term corrosion resistance.

Thermal conductivity

- Benchmark Thermal Conductivity Values for Pure Aluminum and Alloys

- Alloying reduces thermal conductivity

- Efficient Heat Dissipation

- Energy Saving and Reliability

- Lightweight and High Thermal Conductivity

Cast aluminum has good thermal conductivity properties, which makes it excellent in radiators and engine components.

Benchmark Thermal Conductivity Values for Pure Aluminum and Alloys

Pure aluminum has a thermal conductivity of 237 W/m·K (approximately 60% that of copper). Due to its low density, its mass thermal conductivity is twice that of copper.

Alloying reduces thermal conductivity

All added alloying elements (such as Si, Cu, Mg, and Zn) reduce the thermal conductivity of pure aluminum.

Efficient Heat Dissipation

Aluminum alloy has a thermal conductivity approximately three times that of steel and four times that of cast iron, making it an ideal choice for heat sinks, electronic housings, and automotive components.

Energy Saving and Reliability

Rapid heat dissipation lowers operating temperatures, extending lifespan and reducing cooling energy consumption for equipment such as motors and communication base stations.

Lightweight and High Thermal Conductivity

Die-cast aluminum heat sinks are lighter than copper or steel and are also corrosion-resistant.

Mechanical properties

- Strength Range

- Elongation and Toughness

- Fatigue and Shear Properties

The mechanical properties of cast aluminum depend on its alloy composition and microstructure. For example, Al-Si alloys are widely used due to their excellent tensile strength and corrosion resistance, while Al-Cu alloys are favored for their high fracture toughness and good welding properties.

Strength Range

- Ultimate tensile strength (UTS) is generally 219–299 MPa (highest for metal mold casting), approximately 253 MPa for sand casting, and as low as 219 MPa for warm mold casting.

- Specific alloys, such as 333.0 (LM24), have an ultimate tensile strength of 230–280 MPa and a yield strength of 130–210 MPa.

Elongation and Toughness

Typical elongation is low, such as 1.0–2.0% for 333.0 alloy. However, heat-treated A356-T6 alloy can improve plasticity by optimizing its microstructure.

Fatigue and Shear Properties

- The fatigue strength of 333.0 alloy is 83–100 MPa, and the shear strength is 190–230 MPa.

- The shear strength of permanent mold casting is generally higher than that of sand casting.

Properties of cast aluminum Limitations

- Lower Strength Than Steel/Titanium Alloys

- Limited Ductility and Toughness

- Low Wear Resistance and Fatigue Strength

- Challenges of Thin Walls and Complex Structures

- Upper Size Limit

Cast aluminum has poor wear resistance and is prone to deformation at high temperatures, which limits its use in some applications.

Cast aluminum is a material with excellent comprehensive properties. Its lightweight and high-strength characteristics make it occupy an important position in modern industry, but it is also necessary to pay attention to its performance limitations under specific conditions.

Lower Strength Than Steel/Titanium Alloys

- Cast aluminum has lower absolute strength than steel, cast iron, or titanium alloys, making it unsuitable for ultra-high load applications (such as heavy load-bearing structures).

- Wrought aluminum has significantly higher tensile and fatigue strength than cast aluminum, which suffers from weaker mechanical properties due to microporosity and a non-uniform grain structure.

Limited Ductility and Toughness

- Impurities (iron and silicon) in high-copper alloys (such as 201.0) reduce ductility; some alloys (such as 520.0-T4) exhibit room-temperature aging instabilities, with elongation potentially dropping by 80%.

- To improve ductility, strict impurity control (e.g., iron ≤ 0.01%) is required, but this increases production costs.

Low Wear Resistance and Fatigue Strength

- Cast aluminum has poor wear resistance and requires additional surface treatment (such as coating) for high-friction applications.

- Fatigue strength is lower than wrought aluminum, making it susceptible to failure under long-term dynamic loads.

Challenges of Thin Walls and Complex Structures

- Minimum wall thickness is typically ≥0.15 inches (4 mm), and in extreme cases, ≥0.04 inches (1.0 mm). Ultra-thin sections are difficult to mold.

- Complex internal cavity structures are limited by core design (which requires a simple, removable shape).

Upper Size Limit

- Die casting is suitable for small and medium-sized parts (typically <50 kg). Large parts are less cost-effective and are better suited to sand casting or forging.

- The mold size of certain processes (such as die casting) limits production scale.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.